Abstract

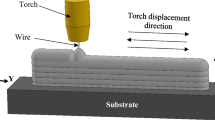

Additive manufacturing (AM) using PBF (powder bed fusion) is widely applied in industry with many advantages but also some drawbacks such as productivity rates and limited dimensions. Future implementations of AM will require a re-design of components in order to reserve AM for the particular complex geometries, to join AM subassemblies or to connect with conventional components. It brings the aspect of weldability of AM parts in the picture. This study is investigating the weldability of AM 316L components using common welding processes such as manual GTAW. Bead-on-plate tests were started as a first step to examine weldability. After satisfactory results, two AM pipe components were fabricated (PBF) in the same built to be welded to conventional 316L parts. One AM pipe component was used to characterize the mechanical properties while the other test coupon was welded to conventional pipe by manual GTAW. The test welds were submitted to a mechanical and corrosion testing program including creep rupture testing. It was decided to start the weldability analysis in the worst condition, i.e., As Build/As Welded (AB/AW) without any heat treatment nor post-processing. Based upon the results obtained for the conditions tested, it could be concluded that AM (PBF) components are weldable.

Similar content being viewed by others

References

Gerhards B, Schleser M, Otten C, Schwarz A, Gebhardt A Innovative laser beam joining technology for additive manufactured parts – 72nd IIW Annual Assembly and Conference, July 2019, proceedings [4970]

Matilanen V-P, Pekkarinen J, Salminen A (2016) Weldability of additive manufactured stainless steel. Phys Procedia 83:807–817 [5030]

Järvinen J-P Welding of additively manufactured stainless steel parts: comparative study between sheet metal and selective laser melted parts – Lappeenranta University of Technology [5031]

Laitinen V Weldability of powder bed fusion fabricated stainless steel 316L sheets to cold-rolled sheet metal - Lappeenranta University of Technology [5032]

Casalino G, Campanelli SL, Ludovico AD (2013) Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int J Adv Manuf Technol 68:209–216 [5034]

Montero Sistiaga ML, Nardone S, Hautfenne C, Van Humbeek J (2016) Effect of heat treatment of 316L stainless steel produced by Selective Laser Melting – 27th Annual International Solid Freedom Fabrication Symposium, proceedings [5039]

De Bruycker E, Montero Sistiaga ML, Thielemans F, Vanmeensel K (2017) Corrosion Testing of a Heat Treated 316L Functional Part produced by Selective Laser Melting. Mater Sci Appl 8:223–233 [5040]

Kujunpää V, Suutala N, Takalo T, Moisio T (1979) Correlation between solidification cracking and microstructure in austenitic and austenitic-ferritic stainless steel welds. Weld Res Int 9(2):55–76 [5193]

Eriksson P Evaluation of mechanical and microstructural properties for laser powder-bed fusion 316L – Uppsala Universitet, Examensarbete 30 hp, Juni 2018 [5095]

Read DT, McHenry HI, Steinmeyer PA, Thomas RD Jr (1980) Metallurgical factors affecting the toughness of 316L SMA weldments at cryogenic temperatures. AWS Weld J 104-s–113-s [5106]

Antony K, Murugan SP (2015) A comparison of corrosion resistance of stainless steel fabricated with selective laser melting and conventional processing. Int J ChemTech Res 7(6):2632–2635 [5038]

Örnek C (2018) Corrosion engineering. Sci Technol 53:531–535 [5101]

Kazemipour M, Nasiri A, Mohammadi M On microstructure and corrosion properties of selective laser melted 316L stainless steel – CSME International Congress 2018 proceedings [5099]

Shaw B, Sikora E, Palmer T, Wang D Impact of nitrogen on pitting and crevice corrosion mechanisms in additively manufactured stainless steels – Penn State University College of Engineering [5098]

Lohdhi MJK, Deen KM, Greenlee-Wacker MC, Haider W (2019) Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications. Addit Manuf 27:8–19 [5097]

Valent EH, Christiansen Thomas L, Somers Marcel AJ The effect of heat treatment and surface hardening of 3D printed austenitic stainless steel AISI 316L on corrosion and wear properties – DTU Library [5100]

Acknowledgements

The authors would like to thank Engie for the financial support of this research project. Also, the industrial partners Engie Fabricom and Element are gratefully acknowledged for support in welding and testing. Special thanks to Ms. E. Peeters, co-author and student at KUL University Leuven-MSc Welding Engineering, for the work performed during her Master Thesis which supplied valuable input for the project. Also special thanks to Mr. P. Alifierakis for demonstrating his superior welding skill during test welding and Mr. L. De Laet for conducting test welding follow-up.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huysmans, S., Peeters, E., De Bruycker, E. et al. Weldability study of additive manufactured 316L austenitic stainless steel components—welding of AM with conventional 316L components. Weld World 65, 1415–1427 (2021). https://doi.org/10.1007/s40194-021-01098-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01098-z