Abstract

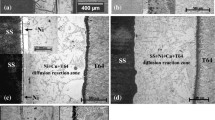

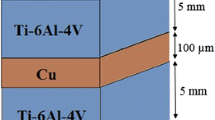

In this work, the diffusion bonding of duplex stainless steel (DSS) and Ti–6Al–4V (Ti64) with and without nickel alloy (NiA) as an interlayer was investigated in the temperature range of 800–950 °C for 30 min in vacuum. Layer wise σ phase and FeTi + λ phase mixture were observed at the DSS | Ti64 bond interface when joints were made at 875 °C and above temperatures; however, when interlayer was used to facilitate the bonding of both DSS and Ti64, layer wise Ni–Ti-based intermetallic was observed at the NiA–Ti64 interface and the bright irregular-shaped Fe5Cr35Ni40Ti15 phase was observed within the Ni3Ti layer, while the DSS–NiA interface was free from any intermetallic. Direct bonded joints (DSS | Ti64) processed at 925 °C achieved the highest tensile strength (∼498.3 MPa) along with substantial ductility, the highest shear strength (∼385.2 MPa), and the highest impact toughness (∼18 J). Usage of interlayer to process the DSS | NiA | Ti64 joints proved to be advantageous than the DSS | Ti64 joints from the point of view of tensile properties, shear strength, and impact toughness of the bonded joints. DSS | Ti64 joints fail either through FeTi + λ phase mixture or σ phase, depending upon the bonding temperature selected, whereas DSS | NiA | Ti64 joints fracture apparently through NiTi2 layer at NiA–Ti64 interface.

Similar content being viewed by others

References

Torun O, Karabulut A, Baksan B, Çelikyürek İ (2008) Diffusion bonding of AZ91 using a silver interlayer. Mater Design 29:2043–2046

Budinski KG, Budinski MK (2010) Engineering materials—properties and selection. PHI Learning, New Delhi

Thirunavukarasu G, Kundu S, Mishra B, Chatterjee S (2014) Effect of bonding temperature on interfacial reaction and mechanical properties of diffusion-bonded joint between Ti-6Al-4V and 304 stainless steel using nickel as an intermediate material. Metall Mater Trans A 45:2067–2077

Thirunavukarasu G, Kundu S, Mishra B, Chatterjee S (2014) Effect of bonding time on interfacial reaction and mechanical properties of diffusion-bonded joint between Ti-6Al-4V and 304 stainless steel using nickel as an intermediate material. Metall Mater Trans A 45:2078–2090

Bai B, Yang HS, Chen N, Mukherjee AK (1999) Anisotropic behavior and constitutive equations of superplastic deformation of a Ti-6Al-4V alloy. Scripta Mater 40:1079–1088

Han W, Zhang K, Wang G (2007) Superplastic forming and diffusion bonding for honeycomb structure of Ti–6Al–4V alloy. J Mater Process Tech 183:450–454

Sheng GM, Huang JW, Qin B, Zhou B, Qiu SY, Li C (2005) An experimental investigation of phase transformation superplastic diffusion bonding of titanium alloy to stainless steel. J Mater Sci 40:6385–6390

Islam MF, Ridley N (1996) Characterisation of diffusion bonds formed between Ti–6Al–4V and titanium aluminide Super Alpha-2. Mater Sci Tech-Lond 12:623–627

Yuan X, Tang K, Deng Y, Luo J, Sheng G (2013) Impulse pressuring diffusion bonding of a copper alloy to a stainless steel with/without a pure nickel interlayer. Mater Design 52:359–366

Zhong Z, Jung H-c, Hinoki T, Kohyama A (2010) Effect of joining temperature on the microstructure and strength of tungsten/ferritic steel joints diffusion bonded with a nickel interlayer. J Mater Process Tech 210:1805–1810

Sabetghadam H, Hanzaki AZ, Araee A (2010) Diffusion bonding of 410 stainless steel to copper using a nickel interlayer. Mater Charact 61:626–634

Zhong Z, Hinoki T, Nozawa T, Park Y-H, Kohyama A (2010) Microstructure and mechanical properties of diffusion bonded joints between tungsten and F82H steel using a titanium interlayer. J Alloy Compd 489:545–551

Chehtov T, Aktaa J, Kraft O (2007) Mechanical characterization and modeling of brazed EUROFER-tungsten-joints. J Nucl Mater 367–370:1228–1232

Özdemir N, Bilgin B (2009) Interfacial properties of diffusion bonded Ti-6Al-4V to AISI 304 stainless steel by inserting a Cu interlayer. Int J Adv Manuf Tech 41:519–526

Boiko NV, Khazov IA, Selezneva LV, Bushmin BV, Semenov AN, Novozhilov SN, Plyshevskii MI, Uvarov AA (2013) Diffusion welding of a titanium alloy to an austenitic steel through intermediate coatings. Weld Int 27:537–539

ASTM (2015) E8/E8M-15a—Standard test methods for tension testing of metallic materials. ASTM, West Conshohocken, PA, www.astm.org

ASTM (2012) E23-12c—Standard test methods for notched bar impact testing of metallic materials. ASTM, West Conshohocken, PA, www.astm.org

He P, Yue X, Zhang JH (2008) Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mat Sci Eng A-Struct 486:171–176

He P, Zhang J, Zhou R, Li X (1999) Diffusion bonding technology of a titanium alloy to a stainless steel web with an Ni interlayer. Mater Charact 43:287–292

Kundu S, Chatterjee S (2008) Characterization of diffusion bonded joint between titanium and 304 stainless steel using a Ni interlayer. Mater Charact 59:631–637

Orhan N, Khan TI, Eroğlu M (2001) Diffusion bonding of a microduplex stainless steel to Ti–6Al–4V. Scripta Mater 45:441–446

Villars P, Prince A, Okamoto H (1995) Handbook of ternary alloy phase diagrams. ASM, Materials Park, Ohio

Kundu S, Sam S, Chatterjee S (2011) Evaluation of interface microstructure and mechanical properties of the diffusion bonded joints of Ti–6Al–4V alloy to micro-duplex stainless steel. Mat Sci Eng A-Struct 528:4910–4916

Alemán B, Gutiérrez I, Urcola JJ (1993) Interface microstructures in diffusion bonding of titanium alloys to stainless and low alloy steels. Mater Sci Tech-Lond 9:633–641

Orhan N, Aksoy M, Eroglu M (1999) A new model for diffusion bonding and its application to duplex alloys. Mat Sci Eng A-Struct 271:458–468

Massalski TB, Okamoto H, Subramanian PR, Kacprzak L (1990) Binary alloy phase diagrams. ASM, Materials Park, Ohio

Yuan XJ, Sheng GM, Qin B, Huang WZ, Zhou B (2008) Impulse pressuring diffusion bonding of titanium alloy to stainless steel. Mater Charact 59:930–936

Laeng J, Xiu Z, Xu X, Sun X, Ru H, Liu Y (2007) Phase formation of Ni–Ti via solid state reaction. Phys Scripta T129:250–254

He P, Zhang J-H, Li X-Q (2001) Diffusion bonding of titanium alloy to stainless steel wire mesh. Mater Sci Tech-Lond 17:1158–1162

Kale GB, Patil RV, Gawade PS (1998) Interdiffusion studies in titanium–304 stainless steel system. J Nucl Mater 257:44–50

Kundu S, Chatterjee S (2006) Effect of bonding temperature on interface microstructure and properties of titanium–304 stainless steel diffusion bonded joints with Ni interlayer. Mater Sci Tech-Lond 22:1201–1207

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Kundu, S., Thirunavukarasu, G. Structure and properties correlation of diffusion bonded joint of duplex stainless steel and Ti–6Al–4V with and without Ni–17Cr–9Fe alloy interlayer. Weld World 60, 793–811 (2016). https://doi.org/10.1007/s40194-016-0327-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0327-7