Abstract

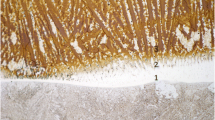

Dissimilar metal weld overlays of nickel base alloys on low alloy steel components are commonly used in the oil and gas, petro-chemical, and power generation industries to provide corrosion and oxidation resistance in a wide range of service environments and temperatures. Traditionally, weld overlays are produced using cold or hot wire gas tungsten arc welding (GTAW). Potential advantages of cold metal transfer (CMT) welding, a low heat input gas metal arc welding process, over the conventional GTAW in production of weld overlays were evaluated. Metallurgical characterization was performed on CMT overlays of Alloy 625 filler metal on Grade 11 and Grade 22 steels. Significant grain refinement was found in the high temperature HAZ compared to the traditional coarse-grained HAZ in arc welding. Evidences of incomplete carbide dissolution, limited carbon diffusion, and incomplete transformation to austenite were also found. These phenomena were related to high heating and cooling rates and short dwell times of the high-temperature HAZ in austenitic state. Tempering effects in the steel HAZ were identified, showing a potential for development of CMT temperbead procedures. Based on the results of this study, the steel HAZ regions in CMT overlays were classified as high-temperature HAZ and intercritical HAZ.

Similar content being viewed by others

Notes

NACE SP0472, Methods and controls to prevent in-service environmental cracking of carbon steel weldments in corrosive petroleum refining environments.

Standard specification for seamless ferritic alloy-steel pipe for high-temperature service

Standard specification for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service

References

M.F. Dodge, H.B. Dong, M. Millititsky, R.P. Barnett, V.F. Marques, M.F. Gittos: Environment-induced cracking in weld joints in subsea oil and gas systems—part 1. 31st International Conference on Ocean, Offshore and Arctic Engineering (OMAE2013).

M.F. Gittos and T.G. Gooch: The interface below stainless steel and nickel-alloy claddings, 1992.

V. Olden, P.E. Kvaale, P.A. Simensen, S. Aaldstedt, J.K. Solberg: The effect of PWHT on the material properties and micro structure in Inconel 625 and Inconel 725 buttered joints. Canun, Mexico, OMAE, 2003. OMAE 2003–37196.

Alexandrov BT, Lippold JC, Sowards JW, Hope AT, Saltzmann DR (2012) Fusion boundary microstructure evolution associated with embrittlement of Ni–base alloy overlays applied to carbon steel. Weld World. doi:10.1007/s40194-012-0007-1

B.T. Alexandrov, J.M. Rodelas, Shu Shi, J.C. Lippold: A new test for evaluation of susceptibility to hydrogen assisted cracking in dissimilar metal welds. NACE International Corrosion Conference and Expo, 51312-01602-SG (2012).AST14 ASTM International: A182/A182M–14: Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service, 2014.

N. McVicker, T. Daniels, B.T. Alexandrov, J.C. Lippold (2014) Application of CMT for dissimilar metal structural weld overlays in nuclear power repair. 11th International EPRI Conference Welding and Repair Technology for Power Plants, Naples, FL, June 2014.

Fronius International, Pettenbach, Austria: Weld and Vision, Welding technology magazine No. 13, 09/2004.

C.F. von Dueren: Formulae for calculating the maximum hardness in the heat affected zone of welded joints, IIW-Doc. IX-1437-86, IIW, 1986.

Easterling K (1992) ‘Introduction to the physical metallurgy of welding’, Butterworth/ Heinemann, Second Edition

Beaugrand VCM, Smith LS,Gittos MF (2009) Subsea dissimilar joints: failure mechanisms and opportunities for mitigation. NACE International Corrosion Conference and Expo, Paper No. 09305

Acknowledgments

This study was supported by ExxonMobil and Fronius International by provision of materials, welding equipment, and technical support, and was performed at the Welding Engineering Laboratory of the Ohio State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Frei, J., Alexandrov, B.T. & Rethmeier, M. Low heat input gas metal arc welding for dissimilar metal weld overlays part I: the heat-affected zone. Weld World 60, 459–473 (2016). https://doi.org/10.1007/s40194-016-0306-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0306-z