Abstract

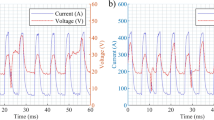

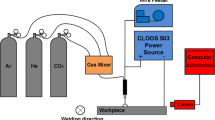

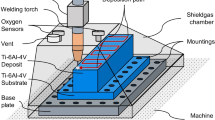

High tensile strength steels (HTSS) are widely used for welded structures, and their strength becomes increasingly high. However, the susceptibility of cold cracking increases as the strength of the steel increases. To avoid cold cracking, low hydrogen welding consumables is used and preheat and interpass temperature is controlled. To lower preheat temperature or to weld without preheat, lower hydrogen welding consumables and process are required. Hydrogen absorption mechanism in gas shielded arc welding is discussed in this paper, and a new developed welding torch for ultra-low hydrogen welding is introduced. Hydrogen in welding wire is present as moisture in flux and lubricating oil at the wire surface. In arc welding, their temperature is increased by Joule heat and then they evaporate into shielding gas. Consequently, shielding gas near welding wire includes much more hydrogen than shielding gas in the gas tanks. This “wet shielding gas” carries hydrogen into arc, and some of hydrogen remains as diffusible hydrogen in the weld metal. “Wet shielding gas” is evacuated and kept away from the arc by using developed torch, resulting in a decrease of the diffusible hydrogen. Evacuating 5 l/min “wet shielding gas” reduces diffusible hydrogen by 50 %.

ᅟ

Similar content being viewed by others

References

Hosoi K et al (2009) Cracking of welded joint. J Japan Welding Soc 78:41–47

Komizo Y (1986) Cracking tendency of steel plates produced by thermo-mechanical control process (TMCP). J Japan Welding Soc 55:153–159

Sato M et al (2009) Welding consumables for 780MPa and 950MPa class high strength steels. J Japan Welding Soc 78:550–554

Kitagawa Y et al (2014) Improvement of cold cracking resistance of weld metal for HT780 class steel, Preprints of the National Meeting of J.W.S 95: 136–137

Kitagawa Y et al (2012) Improvement of resistance for hydrogen cracking of weld metal for HT780 class steel by hydrogen trapping, Preprints of the National Meeting of J.W.S 91: 130–131

Shimizu H et al (2005) Joule heating of solid wires in MAG welding. Quart J Japan Welding Soc 23:25–36

(2004) Edited by The Japan Institute of Metals and Materials: 4th Revised Edition, Metals Data Book, Maruzen Publishing Co., Ltd 14

Nakamura T et al (2002) Wire melting behavior by non-steady heat conduction numerical analysis in gas metal arc welding. Quart J Japan Welding Soc 20:53–62

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Kawabe, N., Maruyama, T., Yamazaki, K. et al. Development of gas shielded arc welding process to achieve a very low diffusible hydrogen content in weld metals. Weld World 60, 383–392 (2016). https://doi.org/10.1007/s40194-016-0305-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0305-0