Abstract

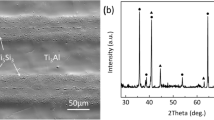

Vacuum brazing of TiAl and Ti3Al was conducted with Ti–Zr–Cu–Ni and Ti–Zr–Fe filler metals. Microstructure and shear strength of TiAl/Ti3Al joints were investigated. The results indicated that the joint mainly consisted of Ti-rich, Ti2Al, and Ti3Al phases and residual filler metal. A columnar structure in all of the brazed seams adjacent to TiAl substrate was found, and it was resulted from the interdiffusion between filler metals and solid-state TiAl substrates. The fracture surface analysis demonstrated that the existence of excessive residual filler metal and the columnar structure was detrimental to joint strength. The joint brazed at 1050 °C for 5 min using Ti–Zr–Fe filler metal presented the maximum shear strength of 196.3 MPa, and the fracture mechanism was characterized by a mixture of cleavage and quasi-cleavage fracture.

Similar content being viewed by others

References

Kim YW (1994) Ordered intermetallic alloys, part III: gamma titanium aluminides. JOM 46:30–39

Suryanarayana C, Froes FH (1994) Nanostructured titanium aluminides. Mater Sci Eng A 179–180:108–111

Ramos AS, Vieira MT, Vieira MF, Viana F (2006) Joining of gamma-based titanium aluminides—a review. Mater Sci Forum 514–516:483–489

Noda T (1998) Application of cast gamma TiAl for automobiles. Intermetallics 12:709–713

Xiong HP, Mao JY, Chen BQ, Wang Q, Wu SB, Li XH (2013) Research advances on the welding and joining technologies of light-mass high-temperature structural materials in aerospace field. J Mater Eng 10:1–12 (In Chinese)

Lee SJ, Wu SK (1999) Infrared joining strength and interfacial microstructures of Ti–48Al–2Nb–2Cr intermetallics using Ti–15Cu–15Ni foil. Intermetallics 7:11–21

Shiue RK, Wu SK, Chen SY (2003) Infrared brazing of TiAl using Al-based braze alloy. Intermetallics 11:661–667

Wallis IC, Ubhi HS, Bacos MP, Josso P, Lindqvist J, Lundstrom D (2004) Brazed joints in γ TiAl sheet: microstructure and properties. Intermetallics 12:303–316

Ye L, Xiong HP, Chen B, Mao W, Cheng YY, Li XH (2010) Microstructures of TiAl joints brazed with CoFe-based and Fe-based high–temperature filler metals. J Mater Eng 10:61–64 (In Chinese)

Shiue RK, Wu SK, Chen YT, Shiue CY (2008) Infrared brazing of Ti50Al50 and Ti–6Al–4V using two Ti-based filler metals. Intermetallics 16:1083–1089

Pan H, Mao W (2009) Key factors effecting on properties of Ti3Al braze joints. J Mater Eng S1:201–215 (In Chinese)

Cadden CH, Yang NYC, Headley TH (1997) Microstructural evolution and mechanical properties of braze joints in Ti–13.4Al–21.2Nb. Weld J Weld Res Suppl 8:316–325

Chen B, Xiong HP, Mao W, Cheng YY, Wu X, Ye L (2010) Microstructure and properties of Ti3Al-based alloy brazing joint when using AgCu-based alloy as filler metal. Weld Join 10:29–32 (In Chinese)

Song XG, Cao J, Chen HY, Wang YF, Feng JC (2012) Brazing TiAl intermetallics using TiNi–V eutectic brazing alloy. Mater Sci Eng A 551:133–139

Xiong HP, Mao W, Xie YH, Guo WL, Li XH, Cheng YY (2007) Brazing of SiC to a wrought nickel-based superalloy using CoFeNi(Si, B)CrTi filler metal. Mater Lett 61:4662–4665

Chang CT, Wu ZY, Shiue RK, Chang CS (2007) Microstructural evolution of infrared brazed Ti–15–3 alloy using Ti–15Cu–15Ni and Ti–15Cu–25Ni fillers. Mater Lett 61:842–845

Yang SJ, Nam SW (2002) Investigation of α2/γ phase transformation mechanism under the interaction of dislocation with lamellar interface in primary creep of lamellar TiAl alloys. Mater Sci Eng A 329–331:898–905

Cao GH, Skrotzki W, Gemming T (2006) Transmission electron microscopy investigation of Ti2Al precipitation in titanium aluminides during high-strain torsion. J Alloys Compd 417:169–172

Xiong HP, Shen Q, Li JG, Zhang LM (2000) Design and microstructures of Ti/TiAl/Al system functionally graded material. J Mater Sci Lett 19:989–993

Herrmann D, Appel F (2009) Diffusion bonding of γ (TiAl) alloys: influence of composition, microstructure, and mechanical properties. Metall Mater Trans A 40:1881–1902

Jung IS, Kim MC, Lee JH, Oh MH, Wee DM (1999) High temperature phase equilibria near Ti–50 at% Al composition in Ti–Al system studied by directional solidification. Intermetallics 7:1247–1253

Lee SJ, Wu SK, Lin RY (1998) Infrared joining of TiAl intermetallics using Ti–15Cu–15Ni foil–I the microstructure morphologies of joint interfaces. Acta Mater 46:1283–1295

Guedes A, Pinto AMP, Vieira MF, Viana F (2003) Joining Ti–47Al–2Cr–2Nb with a Ti/(Cu, Ni)/Ti clad-laminated braze alloy. J Mater Sci 38:2409–2414

Wallis IC, Ubhi HS, Bacos M-P, Josso P, Lindqvist J, Lundstrom D, Wisbey A (2004) Brazed joints in γ TiAl sheet: microstructure and properties. Intermetallics 12:303–316

Lee SJ, Wu SK, Lin RY (1998) Infrared joining of TiAl intermetallics using Ti–15Cu–15Ni foil–II the microstructural evolution at high temperature. Acta Mater 46:1297–1305

Zou GS, Xie EH, Bai HL, Wu AP, Wang Q, Ren JL (2009) A study on transient liquid phase diffusion bonding of Ti–22Al–25Nb alloy. Mater Sci Eng A 499:101–105

Shiue RK, Wub SK, Chen SY (2004) Infrared brazing of TiAl intermetallic using pure silver. Intermetallics 12:929–936

Chen BQ, Xiong HP, Guo SQ, Zhang XJ, Sun BB, Tang SY (2014) Microstructure and mechanical properties of Ti3A1/GH4169 superalloy joints arc welded with NiCuNbCr filler alloy. J Mater Eng 4:13–25 (In Chinese)

Chen BQ, Xiong HP, Sun BB, Tang SY, Guo SQ (2014) Microstructure evolution and tensile properties of Ti3Al/Ni-based superalloy welded joint. J Mater Sci Technol 37(7):715–721

Acknowledgments

This research work was sponsored by Aeronautical Science Foundation of China under grant number 03H21009.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2551, recommended for publication by Commission XVII "Brazing, Soldering, and Diffusion Bonding".

Rights and permissions

About this article

Cite this article

Ren, H.S., Xiong, H.P., Chen, B. et al. Vacuum brazing TiAl to Ti3Al using two Ti-based filler metals. Weld World 59, 639–646 (2015). https://doi.org/10.1007/s40194-015-0239-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0239-y