Abstract

This work is aimed at defining a possible solution for sustainable energy development in the Menoua Department, West Cameroon. The purpose of the cooperation between ALA Milano Onlus and the Biomass Energy Efficiency Laboratory of the University of Modena and Reggio Emilia was to analyze the case study in order to propose a solution for energy production capable of meeting the needs of the Cameroonian society while also heading towards a sustainable development. Primary researches suggested that the most viable solution was to integrate the corn food processing with the gasification of the cobs. The thermo-conversion process was modeled with a black-box approach; the results of the model were further compared with the energy required for corn processing, therefore demonstrating the sustainability and virtuosity of the chosen solution. A commercial 20 kW\(_{el}\) gasifier was selected for supplying electrical power to three central buildings: the city hall, the Chaufferie and the school. This solution is a security measure assuring continue power supply to these vital buildings. Furthermore, it will bind the relation between the rural and the city areas through the energy exchange process.

Similar content being viewed by others

Introduction

Sustainable development has become a much-debated concept, perhaps one of the defining ideas for contemporary societies [1]. From international institutions to local government, from high-level discussions and political platforms to organic and sustainable products and labels, sustainable development has conquered the hearts and minds of many all over the world [2]. In the definition given by the European Union in the “Sustainable Development Strategy”, sustainable development stands for meeting the needs of present generations without jeopardizing the ability of futures generations to meet their own needs [3, 4]. It is therefore a process of growth and progress that integrates short- and long-term objectives with regard to social, economic and environmental issues altogether; calling for an integrated vision towards each and every action we carry out to meet the needs of the present. As a matter or fact, sustainable development is about the whole and the possibility to set up holistic systems. The sustainable development paradigm has also shed new light on development patterns in the Global South too, calling for new forms of development cooperation and assistance. In fact, if it is true that one of the biggest sustainable development challenges arises from unsustainable consumption and production patterns in developed countries, it is also true that the same patterns were followed by developing countries too [5]. The ideal sustainable development is aimed to increase human capabilities and opportunities and to supply adequate energy services, with the final goal to reduce the poverty and to foster both social and economic development. It is precisely the relationship between energy and the social, economic and environmental dimensions that implies a straightforward relationship between energy and sustainable development. In all three areas, the way energy is used and produced plays an essential role.

Fongo Tongo social and energy overview

Fongo Tongo is one of the municipality in the Menoua Department, West Cameroon. The area is populated by about 20,000 people. At the Conference “L’électrification rurale au Cameroun”, the Cameroonian Rural Electrical Agency explained that the lack of energy in rural areas in Cameroon is a critical issue impairing development [6]. Statistics revealed that around 10,000 villages over 13,000 are not provided with energy and the Fongo Tongo Municipality is among them. It is even possible that “Dschang”, the main city, receives no energy for 2 or 3 days in a row. As a matter of fact, rural electrification rate in Cameroon is around 20 %. Among the main causes there is the lack of both means and willingness bound to reduce costs and improve services. Moreover, the use of renewable energies (solar, water, biomasses) is very low. The lack of energy supply is one of the main causes of low levels of economic and social development in the region and low living standards [7]. Modern forms of energy empower human beings in countless ways: by easing life, increasing productivity, transforming food, providing illumination, transporting water, fueling transportation, powering industrial and agricultural processes, cooling or heating rooms, and facilitating electronic communications and computer operations, to name just some of them [8]. With high energy costs and insufficient supply in the municipality, households cannot afford electricity while industrial and agricultural businesses cannot grow, expand or develop. Not to mention the fact that the lack of electricity may hinder the success of other social development programs, such as, for example, educational ones. It is then vital to reduce the impact of the energy problem in Fongo Tongo rural municipality by providing solutions to the main social and energy needs of the area. Namely, actions should be addressed in order to foster the decrease of energy costs, to increase electrical supplies, to strengthen the link between energy and social development. However, such energy and social needs of the region can only be pushed forward through the use of renewable resources. In fact, it is now widely acknowledged that access to reliable and cheap energy sources is one of the leading challenges facing economic development in Cameroonian rural areas. In remote locations, distribution of energy from fossil fuels is extremely difficult and expensive. Moreover, while energy for urban areas and for transportation depends mainly on imported fossil fuels, various sources of biomass are already the dominant and cheap sources of energy for the majority of Africans living in rural areas [9]. In particular, the abundance of biomass and renewable energy sources in the Menoua department should be exploited for greater electrification and for productive uses of electricity.

Sustainable development

One of the most important factors that contribute to achieving sustainable development is the requirement for a supply of energy resources that is both efficient and fully sustainable [10]. Ideally, a society seeking sustainable development utilizes only energy resources which cause no environmental impact. However, no resource can achieve this ideal condition. These statements have at least two implications:

-

1.

Sustainable development requires a supply of cheap, renewable and readily energy [11],

-

2.

Sustainable development requires an use of resources as efficient as possible.

In this way, society maximizes the benefits deriving from its energy resources, while minimizing the negative impacts (such as environmental damage) associated with their use [10, 12]. The previous concepts, put into effect, discard all the technologies that can negatively affect the rural areas object of this study.

The need for new forms of energy production and electrification in rural areas was first addressed in the 1970s and 1980s, when many development assistance agencies attempted to promote green energy such as: biogas, cooking stoves, wind turbines, and solar heaters. Nevertheless, these projects were mainly a failure because of little technical performance and unsuitability for local environment conditions and final user needs, due to an insufficient involvement of relevant stakeholders [7]. Moreover, they also suffered from poor institutional consensus, as well as lack of expertise, sustainable sources of credit, and too little resources were devoted to maintenance costs and to provide local people with the required technical and managerial skills [13]. Finally, even more important, a review of early programs shows that these projects did not take into account the factors for sustainability and further replication. These findings indicate that, in order to foster the use of energy from renewable resources for sustainable development, successful project design and implementation in developing countries should [8]:

-

1.

Link energy with social aspects.

-

2.

Meet real needs of the population.

-

3.

Use the technology that better suits the characteristics of the territory.

-

4.

Be sustainable.

-

5.

Reliable and economically viable in the medium to long term.

At the same time, sustainable development in developing countries should also take into account the preservation of local ecology and biodiversity, and the relationship between biomass and food security should also be addressed. Being a food-deficit continent, the extensive use of food crops to produce biomass for large scale plants in Africa is hardly ethically acceptable as such as they may shift land use, water use, and human and capital resources away from food production. To keep a sustainable balance between food security and energy production, the latter should be based on smallholders and integrated in rural communities. As a matter of fact, energy plants should be small in scale and village-based, that is to say, specifically tailored to address specific local needs.

Even though the previous concepts narrow the aim of the action to agriculture-based technologies for energy production, it is fundamental to analyze the energy demand and further define it according to its final use. In fact, part of the energy is required for the feedstock processing before energy conversion, while the possible energy surplus could be exploited by the Fongo Tongo community for their energy needs. The concepts discussed in the last two paragraphs were used as background for the definition of the solution proposed in terms of energy production and utilization. This solution is defined here as “kick-start idea”, whose primary objective is to bring about a virtuous process of rural-social mutual development.

The kickstart idea

The general survey on the Fongo Tongo area as well as the theoretical constructs derived from the bibliography review on sustainable development in developing countries put several constraints to the possible solution researched in this work. From the energy production point of view, the winning propose consists in the exploitation of byproducts of food crops production process. In this way, the energy production development will propel the food production and viceversa. The best choice for the energy use was picked after a survey with ALA Milano that selected three buildings as the most important for the development of the community: the city Hall, the Chaufferie (native traditional Authority) and the grade school. The interaction between constrains and energy needs resulted in the following idea.

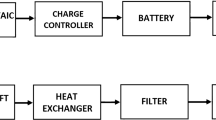

In the Fongo Tongo area will be installed a 20 kW\(_{el}\) commercial gasifier fed with corn cobs. The maize is already cultivated in West Cameroon and there are pre-existing collecting points where the corn is shelled and milled. The byproducts of the process are the corn cobs that did not found a valuable application. The gasifier will be placed in a central point between the three buildings previously chosen, while the mill is about 10 km away. Despite the geographical distance between the cobs collection and energy conversion points, it is fundamental to evaluate if the idea is sustainable from an energy point of view. In particular, the energy produced by cobs gasification has to be higher than the one used for corn processing. The choice of the gasification derives from the high energy conversion efficiency, together with the chance to exploit existing skills on engines to maintain the plant. On the other hand, the gasification of corn cobs is poorly investigated in literature [14–16]. For this reason, the samples of corn cobs were tested in the laboratory while the gasification process was modeled in order to evaluate the overall efficiency and weak points of the proposed solution. Finally, the market offers plants such as the APL Power Pallet [17] that are characterized by low price and simple technology content.

Material and methods

Characterization of cobs feedstock

The first step to take for the correct evaluation of corn cob energy conversion potential is to completely characterize the feedstock. The true density of the cobs was obtained with a helium gas pycnometer. The average value derived from this measurement is 1.36 g/cm\(^{3}\). Instead, the bulk density of the sample is equal to 0.1072 g/cm\(^{3}\). The geometrical properties of the cob pieces were obtained with a series of 45 measurements using a caliper. The average diameter is 20.93 × 10\(^{-3}\) m, the average length is 56.13 × 10\(^{-3}\) m. With these values, the average volume is 198.79 × 10\(^{-7}\)m. Further analyses were made on the sample for the evaluation of the moisture content, ash content and the composition. Finally, the higher heating value of the corn cobs \({\rm HHV_{bio}}\) has been calculated by Eq. 1 starting from the moisture of the biomass \(M\) and the higher heating value of the dry biomass \({\rm HHV_{bio,dry}}\) estimated by Mahler bomb calorimeter [18]:

The results of the characterization measurements are reported in Table 1. These parameters were used as input for the mathematical model of the gasifier, furthermore they can influence the logistic of the power plant affecting the storage volumes [19].

Gasification process modeling

The gasification process was modeled using a black-box model based on Barman’s work [20]. The model generally works for downdraft gasifiers and it is based on the following reaction:

where \({\rm CH}_x {\rm O}_y {\rm N}_z\) is the equivalent chemical formula of “as-received” biomass; \({\rm CH}_p {\rm O}_q\) is the equivalent chemical formula of tar [21]; \(w\) [\({\rm mol/mol}_{\rm bio}\)] in the specific molar amount of the biomass moisture; \(m\) [\({\rm mol/mol}_{\rm bio}\)] in the specific molar amount of oxygen in the inlet air; \(n_{\rm {H_2}},n_{\rm {CO}},n_{\rm {CO_2}},n_{\rm {H_2O}},n_{\rm {CH_4}}\), \(n_{\rm tar}\) [\({\rm mol/mol}_{\rm bio}\)] are the specific molar amount of \({\rm H_2,CO,CO_2,H_2O,CH_4,tar}\) of the syngas. The values of the inputs \(w\) and \(m\) are given by Eqs. 3 and 4.

where \(M\) (%) is the total moisture; \({\rm ER}\) (ad) is the equivalence ratio; \({\rm MW_{bio}}\) (g/mol) is the molecular weight of biomass. The reaction 2 can be multiplied by the molar biomass flow in “daf” conditions \(\dot{n}_{\rm {bio,daf}}\) [\({\rm mol}_{\rm bio}/s\)] in order to assess the molar flow of each component of the syngas as well as the syngas composition in wet and dry conditions. The molar flow of tar is given by Eq. 5, the tar production versus the “daf” biomass input \(x_{\rm tar}\) (% wt. “daf” biomass) is calculated by Eq. 6. Furthermore, Eq. 7 can be used to evaluate the volumetric tar amount \(m_{\rm {tar,vol}}\) (g/Nm\(^3\)) in the syngas.

Moreover, assuming the syngas components as ideal gases it is possible to calculate the normal volumetric flow of wet and dry syngas. Equations 8 and 9 allow us to estimate the “cold gas” efficiency of the gasifier and the \({\rm HHV}\) of the dry syngas.

where \(x_{\rm {H_2}}\), \(x_{\rm {CO}}\), \(x_{\rm {CH_4}}\) (% vol) are the volumetric fraction of \({\rm H_2}\), \({\rm CO}\), \({\rm CH_4}\) in the dry syngas and \({\rm HHV}_{\rm {H_2}}\), \({\rm HHV}_{\rm {CO}}\), \({\rm HHV}_{\rm {CH4}}\) (MJ/Nm\(^3\)) are the Higher Heating Values of \({\rm H_2}\), \({\rm CO}\) and \({\rm CH_4}\).

However, the molar specific amount of the syngas components has to be estimated. An algorithm similar to the one suggested in [22] is adopted here. The first step is to choose an initial temperature \(T\) [K] and calculate the equilibrium constant of the following reactions:

-

K1: Water-gas shift \({\rm CO+H_{2}O \leftrightarrow CO_2 + H_2}\)

-

K2: Hydrogasification \({\rm C+2H_{2} \leftrightarrow CH_{4}}\)

-

K3: Methane steam reforming \({\rm CH_4+H_2O \leftrightarrow CO+3H_2}\)

Equations 10 and 11 are used to calculate \(K_1\) and \(K_2\) [23] and Eq. 12 is used to evaluate \(K_3\) [24]:

Subsequently, the System 13 is solved with the Newton-Raphson method.

Once the molar specific amount of the syngas species is obtained, it is possible to solve the thermodynamic energy balance of the system, reported in Eq. 14, assuming adiabatic conditions in order to find the equilibrium temperature \(T_{\rm {new}}\) with and the Newton-Raphson method.

As reported in [22], if \({\rm abs}(T-T_{\rm {new}})<0.1\) K then the calculated equilibrium temperature and molar specific gases amounts are the final results; instead, a new iteration is done in order to satisfy the previous condition.

where \(n_j\) (moles) and \({\rm HF}_j^0\) (kJ/kmol) are the specific moles amount and standard heat of formation of the jth reagent (biomass, air and moisture); \(n_i\) (moles) and \({\rm HF}_i^0\) (kJ/kmol) are the specific moles amount and the standard heat of formation of the ith product (\({\rm H_2}\), \({\rm CO}\), \({\rm CO_2}\), \({\rm H_2O}\) ,\({\rm CH_4}\) and \({\rm N_2}\)) and \(\Delta H_{T,i}\) is the enthalpy difference between any given state and the standard state for the i-th product. \(\Delta H_{T,i}\) can be calculated starting from the specific heat of the product:

where the coefficients a, b, c and d are tabulated of each gas in [22]. The model was implemented in Python language. In this way once the biomass equivalent molecule is defined, the model works with the only definition of a Equivalence Ratio and a temperature. The temperature input is used only as a starting point for the iterating system, after few cycles the temperature converges to the ones that satisfy both the chemical and thermal sub-systems. The model was tested under several conditions, varying the ER. Table 2 resumes the major results obtained considering a wet flow of syngas. Due to the composition of the feedstock, a working point characterized by low tar content was found with an ER slightly higher than the value suggested for woodchips gasification [25, 26].

Results

Chemical and physical analyses

The feedstock chosen has the major advantage of being a byproduct of the farming process, in fact a research on the population showed that there was not a specific use for the cobs. Furthermore, this particular fuel is characterized by low ash content that is a fundamental feature for low maintenance gasification processes [26]. On the other hand, the major disadvantages are the size of the cobs, the high porosity and the low lignin content [14, 15, 27]. These two factors may influence the behavior of the cobs in the gasifier. First of all, the cobs need to be broken into pieces in order to match the requirements of the gasification system [17], furthermore, due to the porous structure, the dust content in the gas can be higher than the usual values for woodchips gasifiers [14, 15].

System modeling and sustainability

The model was tested with several ERs in order to find a condition were the HHV of the gas was high enough to be efficiently used into a IC engine while the the tar content was low enough to not affect the engine run [25]. The final condition, reported in Table 2, was set with an \({\rm ER}\) of 0.365 that produced a gas with HHV of 4.68 MJ/Nm\(^{3}\) that is perfectly in agreement with the values reported by the fundamental manuals about fixed bed gasifiers [25, 26, 28]. On the other hand, the tar content resulted to be 1.3 g/Nm\(^{3}\). This value is higher than usual for Imbert gasifiers. Nevertheless, even if the cobs produce a non-negligible tar amount, in these plants the syngas is filtered before feeding the engine. The gasification facility chosen in this work uses a biofilter filled with the same biomass used for the gasification process. Here, the corn cobs can counterbalance the not excellent gasification performance with a high filtering capacity.

The system sustainability was evaluated starting form the energy required for corn processing compared to the energy produced by the gasification process. According to CRPA [27, 29], the dried corncob at 9–14 % of moisture content is the 10–11 % of the corn ear. This means that 100 kg of corn is composed of 10–11 kg of dried cobs and 89 kg of grains.

The evaluation of the energy consumption of the sheller and milling process is based on data about a commercial machine able to carry out both the process. The sheller/mill “Nuovo Uni-Bloc” [30] has an average productivity of 260 kg/h of grains with a power consumption of 1.5 kW. This means that the energy required for processing 89 kg of grain is 0.515 kWh.

The model output suggests, for a biomass consumption of 20 kg/h, the production of 47 Nm\(^{3}\)/h of syngas with a HHV of about 4.68 MJ/Nm\(^{3}\). This is equal to 61 kW of syngas chemical power for a consumption of 20 kg/h of corn cobs. Considering the engine conversion efficiency around 25 % for small engines [16, 26], the electrical power output is about 15.24 kW. This means that 10.4 kg of corn cobs produces 7.64 kWh of electrical energy. The electrical energy produced by the gasification of corn cobs is almost 15 times the energy consumed for processing the related amount of grain. Summing up, 100 kg of corn ears can be converted into 89 kg of corn and about 7 kWh of electrical energy which can be easily used to supply local electrical loads. The energy comparison described here is reported in Fig. 1.

Expected effects on rural and city areas

This way, by encouraging farmers to grow biomass crops together with their food crops, they would become the drivers of socially responsible development. As a matter of fact, the local production of energy from the processing of renewable resources, will gradually replace imported conventional fossil fuels (i.e. kerosene). The introduction of the gasification system in the village economy would allow to integrate the ongoing projects on agricultural development with energy production, thus leading to a closed productive cycle. The improvement of the corn agriculture provided by other development projects will allow the increasing of food products on the local market. Overall, the production of energy through the gasification process would have many positive externalizations. For example, increase in agricultural production will lead to an improvement of the employment rates, especially in rural areas such as Fongo Tongo, where the per capita agricultural growth and the rising farm incomes are the real drivers of economic development. Moreover, increase in food production will lead to energy production so that rising farm incomes can be coupled with other economic activities in the medium to long term. In fact productive uses of energy are directly connected to agriculture, small industry, commercial services, and social services like drinking water, education, and health care. These activities will in turn increase incomes and, as incomes increase, rural populations are better able to afford greater levels of energy service, which can allow even greater use of renewable energy. Energy could also empower education, as the School of Fongo Tongo would not be subject to energy cuts, rather, it would benefit from constant energy supply. Finally, social inclusion would be fostered, as women would play a fundamental role in working together to cultivate corn and picking it up. Their role is then very important as they would be actor of all the agricultural activities leading to increase food production and collecting and processing corn cobs. Their direct involvement together with their role within their households and for children’s education, would make women a knowledge hub with regard to sustainable development issues. This would eventually increase the awareness towards environmental issues and amplify the resonance of the whole project. Of course, such externalizations cannot be the result of only one gasifier. The idea behind this study is that energy demand will increase over time. However, this increase, if addressed following the principles of sustainable development, will take into account both the needs of the population and the problems that energy may cause in the long run.

Conclusions

This work laid the foundations of a promising solution for sustainable development in West Cameroon. After an overview of the case study, the efforts were focused on the gasification of corn cobs disposed by the grain shelling process. From a scientific point of view, the energy conversion process was modeled on the basis of the tests run on some cobs samples. The first results are encouraging the research because the corn cobs can be gasified with good efficiency, producing much more energy than the one required for grain processing. In addition, from a sociological point of view, this solution can propel the farming because it gives new valuable outcomes. The facility chosen is capable to power three essential buildings for the Fongo Tongo community: the city hall, the Chaufferie and the school, where the administration, the high places and the future of Fongo Tongo are placed. Asking ourselves to whom is addressed development and with which resources it can be realized is an imperative question. If we forget it, we push the main objective of development itself toward a failure.

References

Sharachchandra, M.: Lele. Sustainable development: a critical review. World Dev. 19(6), 607–621 (1991)

Najam, A., Cleveland, C.J.: Energy and sustainable development at global environmental summits: an evolving agenda. Environ. Dev. Sustain. 5, 117–138 (2003)

EU-SDS.: Review of the european union strategy for sustainable development. Technical report, European Union Strategy for Sustainable Development (2009)

Eurostat.: Sustainable development in the european union, : monitoring report of the eu sustainable development strategy, p. 2011. Publications Office of the European Union, Luxembourg (2011)

(UNDESA). World economic and social survey 2013. Technical report, Department of Economic and Social Affairs of the United Nations Secretariat. United Nations Publications, New York (2013)

Cameroonian Rural Electrical Agency.: L’electrification rurale au cameroun. In: L’electrification rurale au Cameroun, May 27, Doula, Cameroon (2013)

Molteni, M., Masi, A.: Green technology implementation in developing countries: Pursuing environmental-social-economic sustainability. In: ISIRC 2009—International Social Innovation Research Conference, Oxford (UK), September (2009)

AusAID.: Annual report 2001–2002. Technical report, Australian Agency for International Development, (2001)

Wolde-Georgis, T., Glantz, M.H.: Biofuels in africa: A pathway to development. Technical Report 43, International Research Center for Energy and Economic Development Occasional Papers (2009)

Dincerb, Ibrahim, Rosen, Marc A.: Energy, environment and sustainable development. Appl. Energy 64, 427–440 (1999)

Rosen, Marc A., Dincerb, Ibrahim: Exergy as the confluence of energy, environment and sustainable development. Exergy Int. J. 1(1), 3–13 (2001)

Johansson, T.B., Goldemberg, J.: Energy for sustainable development: a policy agenda. Technical report, United Nations Development Programme (2002)

Martinot, Eric, Chaurey, Akanksha, Lew, Debra, Moreira, J.R., Wamukonya, N.: Renewable energy markets in developing countries. Ann. Rev. Energy Environ. 27, 309–348 (2002)

Groeneveld, M.J., Van-Swaaij, W.P.M.: Gasification of solid waste—potential and application of co-current moving bed gasifiers. Appl. Energy 5(3), 165–178 (1979)

Zijp, T., Stassen, H.E.M.: The gasification by partial combustion project in tanzania. Twente University of Technology Report, Enschede, The Netherlands, Technical report (1980)

FAO Forestry Department Mechanical Wood Products Branch.: Woodgas as engine fuel, vol. ISBN 92-5-102436-7. F.A.O. (1986)

All-Power-Labs.: Gasifier experimental kit (2014)

ASTM.: Astm d240–09 standard test method for heat of combustion of liquid hydrocarbon fuels by bomb calorimeter. Technical report, ASTM International (2007)

Anderson, G.A., Bern, C.J.: Dynamic angle of repose of corncobs placed by three mechanical means. Technical report, Agricultural and Biosystems Engineering Pubblications and Paper (1984)

Barman, N.S., Ghosh, S., De, S.: Gasification of biomass in a fixed bed downdraft gasifier—a realistic model including tar. Bioresour. Technol. 107, 505–511 (2012)

Yamazaki, Takashi, Kozu, Hirokazu, Yamagata, Sadamu, Murao, Naoto, Ohta, Sachio, Shiya, Satoru, Ohba, Tatsuo: Effect of superficial velocity on tar from downdraft gasification of biomass. Energy Fuels 19, 1186–1191 (2005)

Jarungthammachote, S., Dutta, A.: Thermodynamic equilibrium model and second law analysis of a downdraft waste gasifier. Energy 32(9), 1660–1669 (2007)

Zainal, Z.A., Ali, R., Lean, C.H., Seetharamu, K.N.: Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers. Manag. 42(12), 1499–1515 (2001)

Bottino, A., Comite, A., Capannelli, G., Di Felice, R., Pinacci, P.: Steam reforming of methane in equilibrium membrane reactors for integration in power cycles. Catal. Today 118, 218–222 (2006)

Basu, P.: Biomass Gasification and Pyrolysis: Practical Design and Theory. Academic Press, Elsevier, Burlington, MA, USA (2010)

Thomas, B.: Reed and Agua Das. The biomass energy foundation press, Handbook of Biomass Downdraft Gasifier Engine Systems (1988)

Blandino, M., Calcagno, M., Ferrero, C., Fabbri, C., Vanzetti, C., Reyneri, A.: Tutolo, sottoprodotto del mais per uso energetico. L’informatore Agrario, Supplemento(43), pp. 11–15 (2013)

Knoef, H.A.M.: Handbook of Biomass Gasification. BTG (2005)

Fabbri, C., Soldano, M., Vanzetti, C., Oddenino, A.: Dal tutolo nel digestore rese in metano molto buone. L’informatore Agrario, Supplemento(43), pp. 16–22 (2013)

Novital.: Catalogo molini e sgranatori (2011). www.novital.it.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the Special Issue "8th AIGE Conference (Italian Association for Energy Management)".

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Allesina, G., Pedrazzi, S., Sgarbi, F. et al. Approaching sustainable development through energy management, the case of Fongo Tongo, Cameroon. Int J Energy Environ Eng 6, 121–127 (2015). https://doi.org/10.1007/s40095-014-0156-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-014-0156-7