Abstract

Background

A study was carried out to classify municipal solid waste (MSW) compost produced in Delhi, India for their marketability and use in different area with respect to physico-chemical properties, fertilizing and heavy metal polluting potentials.

Results

The pH of the compost was slightly alkaline (8.4 ± 0.02) and C:N ratio (9.46 ± 0.91) was low as compared to Fertilizer Control Order (FCO) Standard, Government of India, 1985. Sample analysis was carried out using standard methods. The concentrations of some selected heavy metals, e.g., Zn, Cd and Ni were within the permissible limit of FCO standard. However, the concentrations of Cu, Pb and Cr exceeded (66.7 %) the permissible limit of FCO standard. Further, the compost was characterized to know the fertilizing potential and its potential to contaminate the soil. Fertilizing index (FI) was calculated from the values of TOC, TN, TP, TK and C:N ratio and clean index (CI) was also calculated using heavy metal concentrations. FI value of compost was varied from 4.47 to 4.60, whereas CI value of compost was varied from 2.33 to 2.87, respectively.

Conclusions

The study results indicated that majority of MSW compost produced in Delhi failed to achieve quality control guidelines of FCO standard. The compost has fertilizing potential, however, certain risk to the environment. Hence, the prepared compost in Delhi was not suitable for its intended purpose. Post-treatment of compost is required to improve the quality of compost, which can be utilized for agricultural purposes.

Similar content being viewed by others

Introduction

Municipal solid waste (MSW) management is a grave problem in most of the urban cities in India due to generation of its huge quantity and non-availability of suitable and cost-effective technologies for treatment and disposal (Kumar et al. 2009; Bundela et al. 2010). MSW generation varies from place to place which is directly proportional to socio-economic status of urban population. Urban India generates about 48 million tonnes of MSW per annum. The per capita national MSW generation ranges between 200 and 600 g (CPCB 2010). CSIR-National Environmental Engineering Research Institute (NEERI) in collaboration with Central Pollution Control Board (CPCB) conducted a survey in 59 cities of India in the year 2004–2005 to characterize the MSW generated and finally develop a sustainable solution for MSW management system in India. Out of 59 cities, 35 were metro cities, and 24 were state capitals and union territories. The characterization of MSW based on city population is given in Table 1. Approximately 90 % of the total urban MSW was generated in metro cities and Class I cities during the study period. Door-to-door MSW collection efficiency was 74.57 %. Almost 61 % of Indian cities do not adopt for processing and treatment of MSW. The average generation of MSW from urban cities in India estimated to have approximately 40 to 60 % organic matter could be recycled as compost (Rawat et al. 2013).The wastes are dumped in low-lying areas without any precautions and operational controls henceforth creating nuisance to the environment and human health (CPCB 2010).

The most promising strategies to improve the MSW management system include minimization of the amount of solid wastes generated, maximization of waste recycling as well as resource recovery (Mbuligwe et al. 2002). The application of compost to the agricultural land is a low-cost alternative to open landfill disposal or incineration (Bruun et al. 2006). Compost is a good soil conditioner as it contains major plant nutrients (TN, TP and TK), plant micronutrients (Cu, Fe and Zn) and organic matter which improve soil properties by increasing soil aeration and water holding capacity (Ingelmo et al. 2012). The preparation of MSW compost is a key issue for sustainable agricultural and resource management in India. The cost-effective and sustainable solution in India is due to financial issues as the operation and maintenance cost of compost plant is high as compared to open dumping. Moreover, the majority of MSW compost failed to achieve the requisite specification of FCO, Government of India.

Several European countries, North America and India have adopted specific standards mainly for the purpose of regulating the market of desirable quality of composts (Briton 2000; FAI 2007). The maximum permissible limits for heavy metal contents of composts (mg/kg dry compost) are stipulated by various countries (Table 2). The quality control guidelines failed to identify different grades of quality of marketable compost. It is expected by the user to know about the classification of composts, which can be utilized for different applications such as raising of high value crop, food crops, non-food fiber, soil conditioner, establishment of lawns, reclamation/rehabilitations of mining areas etc.

Delhi, the capital of India, generates approximately 7,000–8,000 tonnes of MSW per day. The waste consists of 54.42 % compostable matter, 15.52 % recyclable matter and 30.06 % inert material on wet weight basis (NEERI, 2005). However, only 5 % (approximately 400–450 tonnes) of MSW per day is processed for composting in Delhi. Approximately 20 % of MSW usually remained unattended in open areas, which is posing health hazards and also causing ecological imbalances to land, water and air (Kansal 2002). The unattended MSW clogs drains, creating stagnant water for insect breeding and floods during the rainy seasons (Alam and Ahmade 2013). The chemical characteristics of generated MSW in Delhi based on % of dry weight basis are presented (Table 3). The calorific value and moisture content of MSW indicated that MSW is not suitable for incineration on received basis. In Delhi, MSW treatment and disposal facility include three landfill locations, which are located at Bhalswa, Gazipur and Okhla. The collection of MSW per day at landfill locations is approximately 5,700–6,200 tonnes (DPCC Report). The existing landfill locations are required to be immediately closed as depth of the landfill is above 12 m. Two more landfill locations are proposed by Delhi government, i.e., Jaitpur and Bawana in Delhi. However, additional landfill locations will only be able to solve the existing problem instead of providing any sustainable solution. A small fraction of MSW (5 % as mentioned earlier) is used for compost production by collaboration of government and private enterprises.

The objective of the study includes characterization of MSW compost; classification of compost in accordance to its fertilizing potential and magnitude of environmental threats due to heavy metal contamination.

Methods

Materials

Compost samples (total 12 nos) were collected from Okhla Compost Plant, Delhi in the year 2008. The plant is surrounded by a diesel filling station, sewage treatment plant and biomedical waste incinerator. It is aerobic compost plant with open windrow system. It is operated and maintained by M/S IL and FS Waste Management and Urban Services Ltd (IWMUSL). Figure 1 shows the location of Okhla Compost Plant in Delhi, India.

Characterisation

Moisture of samples was analyzed by measuring loss of weight at 70 °C. Bulk density was measured in 100 ml measuring cylinder by tapping from 4 cm height. pH and conductivity were measured after making 10 % aqueous solution of samples. pH was measured as per IS:2720 (Part-26),1987. TOC, TN and TP were measured as per IS:10158-1982. Conductivity and TK were measured as per standard method of APHA, 2005. The samples were dried at 105 °C. Dried samples were digested in nitric acid and perchloric acid mixture (5:1 v/v) and analyzed for heavy metals (Zn, Cu, Cd, Pb, Ni, Cr) by Inductively Coupled Plasma (ICP) Analyzer. The heavy metals were analyzed as per standard method APHA 2005. The results of the sample were expressed on dry weight basis except for bulk density, pH and conductivity.

The criteria for ‘weighing factor’ to fertility parameters and ‘score value’ to compost are presented (Table 4). The weighing factor was 5 (maximum) for TOC due to its important role to improve soil productivity. Other selected fertility parameters’ weighing factor was varied from 1 to 5, depending on the capability to improve soil productivity. The FI values of compost are calculated using the following formula.

Where ‘Si’ is the score value and ‘Wi’ is weighing factor of the ith fertility parameter of analytical data.

The criteria for ‘weighing factor’ to heavy metal parameters and ‘score value’ to compost are presented (Table 5). The weighing factor was 5 (maximum) for Cd due to its high mammalian toxicity, medium to low phytotoxicity potential and as a functional role to the organism. Other selected heavy metals’ weighing factor was varied from 1 to 5. The CI values of compost are calculated using the following formula. The higher value of CI indicated lesser heavy metal contamination.

Where S j is the score value and W j is weighing factor of the jth heavy metal of analytical data.

CI value can be used by regulatory authority to restrict the entry of heavy metals to the environment (such as agricultural land, land and water bodies).

Results and Discussion

The characterization of MSW compost and its comparison with FCO standard prescribed by Ministry of Agriculture and Rural Development, Govt. of India is presented (Table 6). The color of the compost was dark brown and had foul odor (NEERI 2009). The particle size of samples was less than 4 mm as against FCO value of minimum 90 %. The moisture content of the sample was 19.3 ± 1.4 %, which is within the permissible limit of FCO standard as recommended value of FCO ranges within 15–25 %. The moisture and oxygen content of the compost is required to be optimum. High moisture content reduces air spaces and hence compost becomes clumpy. However, clumpy compost increases storage and transportation cost. On the other hand, the frequent air ventilation through compost makes the compost dusty causing ambient air pollution within the surrounding areas. The bulk density of the compost was 0.67 g/cm3 against FCO Standard value of 0.7–0.9 g/cm3. The low bulk density of compost is always desirable, which increases water holding capacity of soil, when applied continuously over a longer period of time. The average pH of the compost was 8.4 ± 0.02, which was varied from almost neutral to slightly alkaline as FCO Standard recommended value of 6.5–7.5. High pH accelerates ammonia gas emission from the compost pile to the ambient air. The temperature of the compost pile during the preparation of compost increases due to microbial activity (mesophilic and thermophilic bacteria). The gradual increasing trends of ammonia gas emission (>27 ppm) to ambient air correspond to an increase of compost pile temperature (35–60 °C) and alkaline pH value (7–8.8) (Omrani et al. 2004).The harmful pathogenic bacteria might exist in MSW compost as mixed waste was processed to prepare the compost. The pathogenic bacteria cause illness to the person handling MSW during waste segregation and transportation. However, the analyzed compost samples were not contaminated with pathogenic bacteria. Due to the rise of temperature during composting, pathogens are usually destroyed as they reach to their death point (Day and Shaw 2001). Average EC concentration was within the permissible limit of FCO standard. The average concentrations of TOC, TN, TP and TK of compost were 16.13 ± 0.69, 1.71 ± 0.09, 1.67 ± 0.11 and 0.88 ± 0.27 mg/kg, respectively. The C:N ratio was varied from 8.89 to 10.51 with an average of 9.46 ± 0.91. The C:N ratio was low as compared to FCO Standard as recommended value is 20 (maximum). The survey of MSW characterisation in 59 cities in India indicated that several Indian cities have high C:N ratio (>50) (CPCB 2005). The average concentrations of some selected heavy metal of compost, e.g., Zn, Cu, Cd, Pb. Ni and Cr were 389 ± 42, 326 ± 42.3, 3.95 ± 1.15, 112.6 ± 15, 18.5 ± 7.4 and 85.3 ± 58.7 mg/kg, respectively. The average concentrations of Cu, Pb and Cr exceeded the permissible limit (66.7 %) of FCO Standard. Solid wastes generated in bigger cities were found to contain higher metals as compared to smaller cities (NEERI 1995). The excess heavy metal contents restrict the use of compost to the agricultural land. The effect of compost contaminated with heavy metals in the environment varies according to soil type, plant species and compost quality (Zhao et al. 2011).

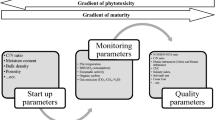

The classification of MSW compost based on marketability and use in different area in accordance to FI and CI value is presented (Table 7). MSW compost is classified to suitable classes A, B, C and D, which are representing good quality compost and allowed to the market for application to agricultural soil. The class of RU-1, 2 and 3 has restricted usage and generally used as soil conditioner or to develop lawns/gardens. Class A and C have maximum FI value and applicable to high value crop. Class A and B have maximum CI value, which indicates minimum heavy metal levels and causes minimum pollution threat to the environment. The FI and CI values of compost of Delhi are shown in Fig. 2. The FI value of compost was varied from 4.47 to 4.60, whereas CI value of compost was varied from 2.33 to 2.87. The prepared MSW compost in Delhi has fertilizing potential (FI value >4) but also has heavy metal polluting potentials (CI value < desired value) due to excess heavy metal concentrations. Hence, the present study indicated that production of MSW compost in Delhi was not suitable for any kind of use.

Conclusions

The classification of compost on the basis of fertilizing potential (FI) and pollution potential (CI) can be used as the tool to identify different grades of quality of marketable compost. It also provides the information about the extent of treatment required before its application to different kinds of use. FI values of MSW compost produced in Delhi achieved the guidelines of quality control compliance, whereas CI values were much below the desired value. This might be due to excess heavy metals in the compost. There are many sources through which heavy metals (majority from electronic and electrical waste) might reach to the compost. The chances of availability of heavy metals in compost are increased when mixed waste/partially segregated waste is processed in the compost plants. The average concentrations of Zn, Cd and Ni of compost of Delhi were within the permissible limit of FCO standard, whereas the average concentrations of Cu, Pb and Cr exceeded (66.7 %) the permissible limit of FCO standard. The soil washing techniques using batch mode are the most suitable techniques for removal of heavy metals from compost, as contaminants are transferred into the liquid phase by desorption and solubilization. The treatment of compost with mixture of Na2S2O5 (reducing reagent) and Na2EDTA (chelating reagent) with different concentrations may increase the removal efficiency of heavy metals from compost. The post-treatment characterization of compost will further determine the quality of compost, which can be utilized for agricultural application.

References

Alam P, Ahmade K (2013) Impact of solid waste on health and the environment. Int J Sustain Develop Green Econ (Special Issue) V-2,1-1,2

APHA (2005) American public health association. Standard methods for examination of waters and wastewaters, Washington, DC, USA. 21st Edn

Briton WF (2000) Compost Quality Standards and Guidelines, Final Report. Woods End Research Laboratory, Inc., USA. http://compost.css.cornell.edu/Brinton.pdf

Bruun JM, Hansen TL, Christensen TH, Magid J, Jensena LS (2006) Application of processed organic municipal solid waste on agricultural land––scenario analysis. Environ Model Assess 11:251–265

Bundela PS, Gautam SP, Pandey AK, Awasthi MK, Sarsaiya S (2010) Municipal solid waste management in Indian cities-A review. Int J Environ Sci 1:4

CPCB (2010) Urban Waste Profile. Parivesh Bhavan, Delhi. Central Pollution Control Board, Ministry of Environment and Forests, Government of India, New Delhi. December, Newsletter. http://cpcb.nic

Day M, Shaw K (2001) Biological, chemical and physical processes of composting in: Stoffella PJ, Kahn BA (eds), Compost Utilization in Horticultural Cropping Systems. Lewis Publishers, Boca Raton, Florida, 17 50

DPCC Report http://dpcc.delhigovt.nic.in/waste.msw.html

ECN. 2008. European Compost Network, http://www.compostnetwork.info/?id=10

FAI (2007) The Fertiliser (Control) Order 1985. The Fertiliser Association of India, 10, Shaheed Jit Singh Marg, New Delhi, India

Ingelmo F, José Molina M, Desamparados Soriano M, Gallardo A, Lapeña L (2012) Influence of organic matter transformations on the bioavailability of heavy metals in a sludge based compost. J. Environment. Manage. 95:104–109

Kansal A (2002) Solid waste management strategies for India: Indian J Environ Protect 22(4):444–448

Kumar S, Bhattacharyya JK, Vaidya AN, Chakrabarti T, Devotta S, Akolkar AB (2009) Assessment of the status of municipal solid waste management in metro cities, state capitals, class I cities, and class II towns in India: an insight. Waste Manag 29:883–895

Mbuligwe SE, Kassenga GR, Kaseva ME, Chaggu EJ (2002) Potential and constraints of composting domestic solid waste in developing countries: findings from a pilot study in Dar es Salaam, Tanzania. Resour Conserv Recycl 36:45–59

NEERI (2005) Strategy paper on SWM in India. Natl Environ Eng Res Inst, Nagpur

NEERI (2009) Assessment of Quality of Compost from Waste Processing Plants of Calicut Delhi and Jalandhar. Environ Eng Res Inst, Nagpur

Omrani G, Safa M, Ghafghazy L (2004) Utilization of biofilter for ammonia elimination in composting plant. Pak J Biol Sci 30:192–201

Rawat M, Ramanathan AL, Kuriakose T (2013) Characterisation of Municipal Solid Waste Compost (MSWC) from selected Indian Cities-A case study for its sustainable utilization. J Environ Prot 4:163–171

Saha JK, Panwar N, Singh MV (2010) An assessment of municipal solid waste compost quality produced in different cities of India in the perspective of developing quality control indices. Waste Manag 7(11):2009–2013

Zhao S, Lian F, Duo L (2011) EDTA-assisted phytoextraction of heavy metals by turfgrass from municipal solid waste compost using permeable barriers and associated potential leaching risk. Bioresour Tech 102:621–626

Acknowledgments

The authors acknowledge the IL and FS Waste Management and Urban Services Ltd, Delhi in facilitating and supporting the project activities. The authors are also thankful to the Director NEERI for giving permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Mandal, P., Chaturvedi, M.K., Bassin, J.K. et al. Qualitative assessment of municipal solid waste compost by indexing method. Int J Recycl Org Waste Agricult 3, 133–139 (2014). https://doi.org/10.1007/s40093-014-0075-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40093-014-0075-x