Abstract

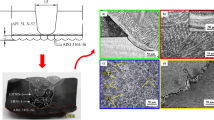

P-91 is modified 9Cr–1Mo steel. Fabricated structures and components of P-91 has a lot of application in power and chemical industry owing to its excellent properties like high temperature stress corrosion resistance, less susceptibility to thermal fatigue at high operating temperatures. The weld quality and surface finish of fabricated structure of P91 is very good when welded by Tungsten Inert Gas welding (TIG). However, the process has its limitation regarding weld penetration. The success of a welding process lies in fabricating with such a combination of parameters that gives maximum weld penetration and minimum weld width. To carry out an investigation on the effect of the autogenous TIG welding parameters on weld penetration and weld width, bead-on-plate welds were carried on P91 plates of thickness 6 mm in accordance to a Taguchi L9 design. Welding current, welding speed and gas flow rate were the three control variables in the investigation. After autogenous (TIG) welding, the dimension of the weld width, weld penetration and weld area were successfully measured by an image analysis technique developed for the study. The maximum error for the measured dimensions of the weld width, penetration and area with the developed image analysis technique was only 2 % compared to the measurements of Leica-Q-Win-V3 software installed in optical microscope. The measurements with the developed software, unlike the measurements under a microscope, required least human intervention. An Analysis of Variance (ANOVA) confirms the significance of the selected parameters. Thereafter, Taguchi’s method was successfully used to trade-off between maximum penetration and minimum weld width while keeping the weld area at a minimum.

Similar content being viewed by others

References

J. Brozda, M. Lomozik, M. Zeman, A welding of P91 steel to other grades of steel for elevated temperature service. Weld. Int. 12(7), 509–518 (1998)

A. Di Gianfrancesco, O. Tassa, S. Matera, G. Cumino, High Alloy Ferritic Steel: Mechanical and Creep Properties and its Microstructural Evolution, in Advanced Heat Resistant Steel for Power Generation, ed. by R. Viswanathan, J. Nutting (The University Press, Cambridge, 1999), pp. 622–632

ASTM, Designation: A387/A387M-06a, Standard Specification for Pressure Vessel Plates, Alloy Steel, Chromium–Molybdenum

Y. Hasegawa, M. Ohgami, Y. Okamura, Creep Properties of Heat Affected Zone of Weld in W Containing 9–12 % Chromium Creep Resistant Martensitic Steels at Elevated Temperature, in Advanced Heat Resistant Steel for Power Generation, ed. by R. Viswanathan, J. Nutting (The University Press, Cambridge, 1999), pp. 655–667

L. Subashini, P. Madhumitha, M. Vasudevan, Optimisation of welding process for modified 9Cr–1Mo steel using genetic algorithm. Int. J. Comput. Mater. Sci. Surf. Eng. 5(1), 1–15 (2012)

V. Maduraimuthu, M. Vasudevan, V. Muthupandi, A.K. Bhaduri, T. Jayakumar, Effect of activated flux on the microstructure, mechanical properties, and residual stresses of modified 9Cr–1Mo steel weld joints. Metal. Mater. Trans. B 43b, 123–132 (2012)

V. Maduraimuthu, M. Vasudevan, V. Muthupondi, T. Jayakumar, Study of the effect of activated flux on the microstructure and mechanical properties of mod. 9Cr–1Mo steel. Metal. Mater. Trans. B 43(1), 123–132 (2012)

V. Arunkumar, M. Vasudevan, V. Maduraimuthu, V. Muthupandi, Effect of activated flux on the microstructure and mechanical properties of 9Cr–1Mo steel weld joint. Mater. Manuf. Processes 27(11), 1171–1177 (2012)

B. Arivazhagan, M. Vasudevan, A study of microstructure and mechanical properties of grade 91 steel A-TIG weld joint. J. Mater. Eng. Perform. 22(12), 3708–3716 (2013)

B. Arivazhagan, M. Vasudevan, A comparative study on the effect of GTAW processes on the microstructure and mechanical properties of P91 steel weld joints. J. Manuf. Processes 16, 305–311 (2014)

V. Maduraimuthu, M. Vasudevan, P. Parameswaran, Studies on Improvement of Toughness in Modified 9Cr–1Mo Steel A-TIG Weld Joint. Trans. Indian Inst. Met. 68(2), 181–189 (2015)

K.H. Dhandha, V.J. Badheka, Effect of activating fluxes on weld bead morphology of P91 steel bead-on-plate welds by flux assisted tungsten inert gas welding process. J. Manuf. Processes 17, 48–57 (2015)

T.B. Jefferson, The Welding Encyclopedia, 13th edn. (McGraw-Hill, New York, 1951). 491

E.T. Gill, E.N. Simons, Modern Welding Techniques (Sir Issac Pitman and sons Ltd., London, 1950). 120

C.E. Jackson, The science of arc welding—Part III. Weld. J. 39(6), 25s–230s (1960)

Indian Standard Institution, IS: 812 (1957)

A. Shumovsky, Controlling welding shrinkage and distortion. Can. Weld. 192, 179–180 (1952)

C. Cookson, Quench welding process for joining cast-iron. Weld. Met. Fabr. 38(8), 319–323 (1970)

C.F. Meitzner, R.D. Stout, Micro-cracking and delayed cracking in welded quenched and tempered steels. Weld. J. 45(9), 381s–386s (1966)

A.K. Singh, T. Debnath, V. Dey, R.N. Rai, A Study on effect of preheating and post weld heat treatment (PWHT) of grade P91 steel. J. Mater. Sci. Mecha. Eng. 2(8), 57–62 (2015)

W. Chen, B.A. Chin, Monitoring joint penetration using infrared sensing techniques. Weld. J. 67, 181–185 (1988)

H.C. Wikle, S. Kottilingam, R.H. Zee, B.A. Chin, Infrared sensing techniques for penetration depth control of the submerged arc welding process. J. Mater. Process. Technol. 113, 228–233 (2001)

M. Menaka, M. Vasudevan, B. Venkatraman, B. Raj, Estimating bead width and depth of penetration during welding by infrared thermal imaging. J. British Inst. NDT 47(9), 564–568 (2005)

H.S. Song, Y.M. Zhang, Measurement and analysis of three-dimensional specular gas tungsten arc weld pool surface. Welding Research, Supplement to the Welding Journal, Sponsored by the American Welding Society and the Welding Research Council (2008)

Y. Xu, H. Yu, J. Zhong, T. Lin, S. Chen, Real-time seam tracking control technology during welding robot GTAW process based on passive vision sensor. J. Mater. Process. Technol. 212, 1654–1662 (2012)

M. Fidali, W. Jamrozik, Diagnostic method of welding process based on fused infrared and vision images. Infrared Phys. Technol. 61, 241–253 (2013)

Y. Xu, G. Fang, N. Lv, S. Chen, J.J. Zou, Computer vision technology for seam tracking in robotic GTAW and GMAW. Robot. Compu. Integr. Manuf. 32, 25–36 (2015)

M. El. Rayes, C. Walz, G. Sepold, The influence of various hybrid welding parameters on bead geometry. Welding Research, Supplement to the Welding Journal (2004)

D.S. Nagesh, G.L. Datta, Prediction of weld bead geometry and penetration in shielded metal-arc welding using artificial neural networks. J. Mater. Process. Technol. 123, 303–312 (2002)

K.M. Kanti, P.S. Rao, Prediction of bead geometry in pulsed GMA welding using back propagation neural network. J. Mater. Process. Technol. 200, 300–305 (2008)

P. Ghanty, M. Vasudevan, N. Chandrasekhar, D. Mukherjee, V. Maduraimuthu, R.N. Pal, A.K. Bhaduri, P. Bharat, B. Raj, An artificial neural network approach for estimating weld bead width and depth of penetration from infrared thermal image of weld pool. Sci. Technol. Weld. Joining 13(4), 395–401 (2008)

Sreeraj P, Kannan T, Maji S (2013) Genetic algorithm for optimization of welding variables for percentage of dilution and application of ANN for prediction of weld bead geometry in GMAW process. Mechanica Confab 2(1) (2013)

P. Sreeraj, T. Kannan, S. Maji, Prediction and control of weld bead geometry in gas metal arc welding process using simulated annealing algorithm. Int. J. Comput. Eng. Res. 3, 213–222 (2013)

V. Dey, D.K. Pratihar, G.L. Datta, M.N. Jha, T.K. Saha, A.V. Bapat, Optimization of bead geometry in electron beam welding using a genetic algorithm. J. Mater. Process. Technol. 209, 1151–1157 (2009)

E.B. Dasgupta, S. Mukherjee, Optimisation of weld bead parameters of nickel based overlay deposited by plasma transferred arc surfacing. Int. J. Mod. Eng. Res. 3, 1330–1335 (2013)

P. Sreeraj, T. Kannan, S. Maji, Optimization of weld bead geometry for stainless steel cladding deposited by GMAW. Am. J. Eng. Res. 2, 178–187 (2013)

V. Dey, D.K. Pratihar, G.L. Datta, M.N. Jha, T.K. Saha, A.V. Bapat, Optimization and prediction of weldment profile in bead-on-plate welding of Al-1100 plates using electron beam. Int. J. Adv. Manuf. Technol. 48, 513–515 (2010)

Dey V, Pratihar DK, Datta GL (2010) Hybrid Optimization Scheme for Radial Basis Function Neural Network. Springer-Verlag, Berlin, Heidelberg, K. Deb et al. (eds.) SEAL 2010, LNCS 6457, 613–622 (2010)

M. Manikandan, M.N. Rao, R. Ramanujam, D. Ramkumar, N. Arivazhagan, G.M. Reddy, Optimization of the pulsed current gas tungsten arc welding process parameters for alloy C-276 using the Taguchi method. Procedia Eng. 97, 767–774 (2014)

G. Magudeeswaran, S.R. Nair, L. Sundar, N. Harikannan, Optimization of process parameters of the activated tungsten inert gas welding for aspect ratio of UNS S32205 duplex stainless steel weld. Def. Technol. 10, 251–260 (2014)

S.C. Juang, Y.S. Tarng, Process parameter selection for optimizing the weld pool geometry in the tungsten inert gas welding of stainless steel. J. Mater. Process. Technol. 122, 33–37 (2002)

Y.S. Tarng, W.H. Yang, Optimisation of the weld bead geometry in gas tungsten arc welding by the Taguchi method. Int. J. Adv. Manuf. Technol. 14, 549–554 (1998)

S. Datta, A. Bandyopadhyay, P.K. Pal, Application of Taguchi philosophy for parametric optimization of bead geometry and HAZ width in submerged arc welding using a mixture of fresh flux and fused flux. Int. J. Adv. Manuf. Technol. 36(7–8), 689–698 (2008)

M. Yousefieh, M. Shamanian, A. Saatchi, Optimization of experimental conditions of the pulsed current GTAW parameters for mechanical properties of SDSS UNS S32760 welds based on the Taguchi design method. JMEPEG 21, 1978–1988 (2012)

R.C. Gonzalez, R.E. Woods, S.L. Eddins, Digital Image Processing Using MATLAB, 2nd edn. (Tata McGraw Hill Education Private Limited, New Delhi, 2010)

Acknowledgments

The authors acknowledge the financial assistance provided by TEQIP phase II at National Institute of Technology Agartala India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A.K., Debnath, T., Dey, V. et al. An Approach to Maximize Weld Penetration During TIG Welding of P91 Steel Plates by Utilizing Image Processing and Taguchi Orthogonal Array. J. Inst. Eng. India Ser. C 98, 541–551 (2017). https://doi.org/10.1007/s40032-016-0268-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0268-3