Abstract

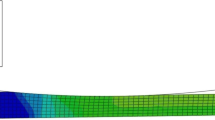

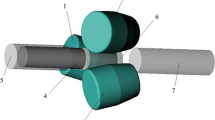

Studies on the effect of strain path during rolling has been carried out for a long time, but the same has not been done using Finite Element Analysis (FEA). Change in strain path affects the state variables in the rolled plate like stress, strain, temperature etc. In the current work, Finite Element Analysis for cross rolling of AISI 304 austenitic stainless steel has been carried out by rotating the plate by 90° in between the passes. To analyze stress and strain fields in the material for cross rolling, a full 3D model of work-roll and plate has been developed using rigid-viscoplastic finite element method. The stress and strain fields, considering von-Mises yield criteria, are calculated by using updated Lagrangian method. In addition to these, the model also calculates the normal pressure and strain rate distribution in the plate during cross rolling. The nature of the variations of stress and strain fields in the plate, predicted by the model, is in good agreement with the previously published works for unidirectional rolling.

Similar content being viewed by others

References

L. Yang et al., Prediction of process parameters on stress and strain fields in hot rolling process using finite element method. Inf. Technol. J. 10(12), 2406–2412 (2011)

C. Vallellano et al., Analysis of deformations and stresses in flat rolling of wire. J. Mater. Process. Technol. 195(1–3), 63–71 (2008)

S. Serajzadeh et al., An investigation on strain inhomogeneity in hot strip rolling process. J. Mater. Process. Technol. 128, 88–99 (2002)

U.S. Dixit, P.M. Dixit, Finite-element analysis of flat rolling with inclusion of anisotropy. Int. J. Mech. Sci. 39(11), 1237–1255 (1997)

X. Duan, T. Sheppard, Three dimensional thermal mechanical coupled simulation during hot rolling of aluminium alloy 3003. Int. J. Mech. Sci. 44, 2155–2172 (2002)

R. Riahifar, S. Serajzadeh, Three-dimensional model for hot rolling of aluminum alloys. Mater. Des. 28(8), 2366–2372 (2007)

Z. Ben, W. Jing, Z. Heng-hua, Numerical simulation of multi-pass rolling force and temperature field of plate steel during hot rolling. J. Shanghai Jiaotong Univ. (Sci.) 16(2), 141–144 (2011)

S.K. Pal et al., Bond graph and finite element analyses of temperature distribution in a hot rolling process: a comparative study. J. Syst. Control Eng. 221, 653–661 (2007)

M. Bagheripoor, H. Bisadi, Effects of rolling parameters on temperature distribution in the hot rolling of aluminum strips. Appl. Therm. Eng. 31(10), 556–1565 (2011). http://dx.doi.org/10.1016/j.applthermaleng.2011.01.005

S. Kobayashi, S.I. Oh, T. Altan, Metal Forming and the Finite-Element Method (Oxford University Press, Oxford, 1989)

G. Li, S. Kobayashi, Rigid-plastic finite-element analysis of plane strain rolling. J. Eng. Ind. 104(1), 55 (1982)

A.R. Shahani et al., Prediction of influence parameters on the hot rolling process using finite element method and neural network. J. Mater. Process. Technol. 209(4), 1920–1935 (2009)

DEFORM material library. Scientific forming technology corporation (SFTC), Columbus, Ohio

Acknowledgments

The present paper is an extended version of the paper titled ‘Finite Element Analysis of Cross Rolling on AISI 304 Stainless Steel: Prediction of Stress and Strain Fields’ presented in 5th International and 26th All India Manufacturing Technology, Design and Research (AIMTDR) Conference held at Indian Institute of Technology Guwahati, India during December 12–14, 2014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rout, M., Pal, S.K. & Singh, S.B. Finite Element Analysis of Cross Rolling on AISI 304 Stainless Steel: Prediction of Stress and Strain Fields. J. Inst. Eng. India Ser. C 98, 27–35 (2017). https://doi.org/10.1007/s40032-016-0239-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0239-8