Abstract

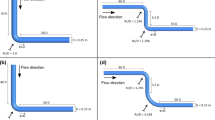

Sudden change in geometry of pressure vessel due to nozzle cutout, leads to local stress concentration and deformation, decreasing its strength. Elastic plastic analysis of cylindrical pressure vessels with different inclination angles of nozzle is important to estimate plastic limit load. In the present study, cylindrical pressure vessels with combined inclination of nozzles (i.e. in longitudinal and radial plane) are considered for elastic plastic limit load analysis. Three dimensional static nonlinear finite element analyses of cylindrical pressure vessels with nozzle are performed for incremental pressure loading. The von Mises stress distribution on pressure vessel shows higher stress zones at shell–nozzle junction. Approximate plastic limit load is obtained by twice elastic slope method. Variation in limit pressure with different combined inclination angle of nozzle is analyzed and found to be distinct in nature. Reported results can be helpful in optimizing pressure vessel design.

Similar content being viewed by others

Abbreviations

- d :

-

Nozzle diameter (mm)

- D :

-

Shell diameter (mm)

- l :

-

Nozzle length (mm)

- L :

-

Shell length (mm)

- P l :

-

Limit pressure (MPa)

- P A :

-

Allowable pressure (MPa)

- P Φ :

-

Plastic limit pressure by TESM (MPa)

- P TIM :

-

Plastic limit pressure by TIM (MPa)

- o :

-

Height of nozzle head (mm)

- O :

-

Height of vessel head (mm)

- r :

-

Nozzle radius (mm)

- t :

-

Nozzle thickness (mm)

- R :

-

Shell radius (mm)

- T :

-

Shell thickness (mm)

- α :

-

Nozzle inclination angle in section XX (°)

- β :

-

Nozzle inclination angle (°)

References

S.S. Gill, The limit pressure for a flush cylindrical nozzle in a spherical pressure vessel. Int. J. Mech. Sci. 6, 105–115 (1964)

J.L. Mershon, Interpretive report on oblique nozzle connections in pressure vessel heads and shells under internal pressure loading. Weld. Res. Counc. Bull. 153, 1–3 (1970)

A.T. Junker, Finite element determination of limit load for a nozzle in a cylinder vessel under internal pressure. ASME Paper No. 82-PVP-10 (1980)

J. Schroeder, Limit and burst pressures of fabricated branch connections. ASME Paper No. 82-PVP-16 (1982)

Z. Sanal, Nonlinear analysis of pressure vessels: some examples. Int. J. Press. Vessel Pip. 77, 705–709 (2000)

Z.F. Sang, Y. Lin, L.P. Xue, G.E.O. Widera, Limit and burst pressures for a cylindrical shell intersection with intermediate diameter ratio. Int. J. Press. Vessel Pip. 79(5), 341–349 (2002)

M. Muscat, D. Mackenzie, R. Hamilton, A work criterion of plastic collapse. Int. J. Press. Vessel Pip. 80, 49–58 (2003)

Z.F. Sang, Y.J. Lin, L.P. Xue, G.E.O. Widera, Limit and burst pressures for a cylindrical vessel with a 30 deg—lateral (d/D ≥ 0.5). J. Press. Vessel Technol. 127(1), 61–69 (2005)

Z.F. Sang, Z.L. Wanga, L.P. Xue, G.E.O. Widera, Plastic limit loads of nozzles in cylindrical vessels under out-of-plane moment loading. Int. J. Press. Vessel Pip. 82, 638–648 (2005)

Z.F. Sang, H.F. Wang, L.P. Xue, G.E.O. Widera, Plastic limit loads of pad reinforced cylindrical vessels under out-of-plane moment of nozzle. J. Press. Vessel Technol. 128(1), 49–56 (2006)

G.C. Slagis, ASME section III design-by-analysis criteria concepts and limits. J. Press. Vessel Technol. 128(1), 25–32 (2006)

G.H. Rahimi, R.A. Alashti, Lower bound to plastic load of cylinders with opening under combined loading. Thin Walled Struct. 45, 363–370 (2007)

R.A. Alasti, G.H. Rahiib, E. Poursaeidic, Plastic limit load of cylindrical shells with cut-outs subject to pure bending moment. Int. J. Press. Vessel Pip. 85, 498–506 (2008)

N. Li, Z.F. Sang, G.E.O. Widera, Study of plastic limit load on pressurized cylinders with lateral nozzle. J. Press. Vessel Technol. 130(4), 041210 (2008)

P. Gao, N. Li, Z.F. Sang, G.E.O. Widera, Elastic behavior of cylindrical vessels with lateral nozzle under internal pressure. J. Press. Vessel Technol. 131(5), 051207 (2009)

P. Yang, Y. Liu, Y. Ohtake, H. Yuan, Z. Cen, Limit analysis based on a modified elastic compensation method for nozzle-to-cylinder junctions. Int. J. Press. Vessel Pip. 82(10), 770–776 (2005)

ASME boiler and pressure vessel code. Section VIII, Division 2 (2004)

G.E.O. Widera, Z. Wei, Parametric finite element analysis of large diameter shell intersection (internal pressure). Weld. Res. Counc. Bull. 497, 10–45 (2004)

ASME Boiler and Pressure Vessel Code. Section II, Part A (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prakash, A., Raval, H.K., Gandhi, A. et al. Plastic Limit Load Analysis of Cylindrical Pressure Vessels with Different Nozzle Inclination. J. Inst. Eng. India Ser. C 97, 163–174 (2016). https://doi.org/10.1007/s40032-015-0210-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-015-0210-0