Abstract

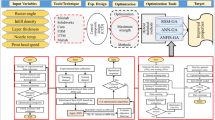

This work aims to optimize the formability and surface roughness of parts formed by the single-point incremental forming process for an Aluminium-6063 alloy. The tests are based on Taguchi’s L18 orthogonal array selected on the basis of DOF. The tests have been carried out on vertical machining center (DMC70V); using CAD/CAM software (SolidWorks V5/MasterCAM). Two levels of tool radius, three levels of sheet thickness, step size, tool rotational speed, feed rate and lubrication have been considered as the input process parameters. Wall angle and surface roughness have been considered process responses. The influential process parameters for the formability and surface roughness have been identified with the help of statistical tool (response table, main effect plot and ANOVA). The parameter that has the utmost influence on formability and surface roughness is lubrication. In the case of formability, lubrication followed by the tool rotational speed, feed rate, sheet thickness, step size and tool radius have the influence in descending order. Whereas in surface roughness, lubrication followed by feed rate, step size, tool radius, sheet thickness and tool rotational speed have the influence in descending order. The predicted optimal values for the wall angle and surface roughness are found to be 88.29° and 1.03225 µm. The confirmation experiments were conducted thrice and the value of wall angle and surface roughness were found to be 85.76° and 1.15 µm respectively.

Similar content being viewed by others

References

M. Ham, J. Jeswiet, Single point incremental forming and the forming criteria for AA3003. CIRP Ann. Manuf. Technol. 55, 241–244 (2006)

J.-J. Park, Y.-H. Kim, Fundamental studies on the incremental sheet metal forming technique. J. Mater. Process. Technol. 140, 447–453 (2003)

R. Crina, Determination of the maximum forming angle of some carbon steel metal sheets. J. Eng. Stud. Res. 17, 71–74 (2011)

W.K.H. Sarraji, J.H. Mohamed, W.X. Ren, An experimental investigation of some relevant process parameters affecting formed thickness in ISMF process. Eng. Technol. J. 28, 925–940 (2010)

A. Blaga, V. Oleksik, O. Bologa, R. Breaz, Experimental studies and FEM analysis regarding the influence of geometric parameters on strain, thickness reduction and forces in incremental forming process. Annals "Eftimie Murgu" Resita Engineering harness. ANUL XVIII NR.3, 43–54 (2011)

S.C. Babu, V.S.S. Kumar, Effect of process variables during incremental forming of deep drawing steel sheets. Eur. J. Sci. Res. 80, 50–56 (2012)

C.C. Cavaler, L. Schaeffer, A.S. Rocha, F. Peruch, Surface roughness in the incremental forming of AISI 304l stainless steel sheets. Far East J. Mech. Eng. Phys. 1, 87–98 (2010)

G. Hussain, L. Gao, A novel method to test the thinning limits of sheet metals in negative incremental forming. Int. J. Mach. Tools Manuf 47, 419–435 (2007)

M. Pohlak, J. Majak, R. Küttner, Manufacturability and limitations in incremental sheet forming. Proc. Estonian Acad. Sci. Eng. 13, 129–139 (2007)

M.L. Alves, M.B. Silva, L.M. Alves, P.A.F. Martins, On the formability, geometrical accuracy and surface quality of sheet metal parts produced by SPIF. Int. Conf. Exp. Mech. 7375, 73750N1–73750N7 (2008)

Rattanachan, Chungchoo, Formability in single point incremental forming of dome geometry. AIJSTPME 2, 57–63 (2009)

G. Hussain, L. Gao, N. Hayat, N.U. Dar, The formability of annealed and pre-aged AA-2024 sheets in single-point incremental forming. Int. J. Adv. Manuf. Technol. 46, 543–549 (2010)

R. de Bruyn, N.F. Treurnicht, An investigation into lubrication strategies for the incremental sheet forming of Ti-6Al-4V. in CIE42 Proceedings (2012), pp. 16–18

I. Cerro, E. Maidagan, J. Arana, A. Rivero, P.P. Rodrıguez, Theoretical and experimental analysis of the dieless incremental sheet forming process. J. Mater. Process. Technol. 177, 404–408 (2006)

P.J. Ross, Taguchi Techniques for Quality Engineering (McGraw Hill Book Company, New York, 1996)

L. Carrino, N. Di Meo, L. Sorrentino, M. Strano, The influence of friction in the negative dieless incremental forming process, in 9th International ESAFORM Conference on Material Forming, Glasgow (UK) (2004)

Y.H. Kim, J.J. Park, Effect of process parameters on formability in incremental forming of sheet metal. J. Mater. Process. Technol. 130–131, 42–46 (2002)

E. Hagan, J. Jeswiet, Analysis of surface roughness for parts formed by computer numerical controlled incremental forming. Proc. Inst. Mech. Eng. J. Eng. Manuf. 218, 1307–1312 (2004)

J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou, J. Allwood, Asymmetric single point incremental forming of sheet metal. CIRP Ann. 54, 623–650 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gulati, V., Aryal, A., Katyal, P. et al. Process Parameters Optimization in Single Point Incremental Forming. J. Inst. Eng. India Ser. C 97, 185–193 (2016). https://doi.org/10.1007/s40032-015-0203-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-015-0203-z