Abstract

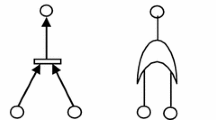

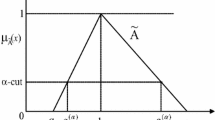

This paper presented a methodology, named as confidence interval based lambda-tau, for analyzing the behavior of complex repairable industrial systems by utilizing vague, uncertain and imprecise data. In this, uncertainties in the data related to each component of the system are estimated with the help of fuzzy and statistical methodology. Triangular fuzzy numbers are used for this purpose as it allows expert opinions, operating conditions, uncertainty and imprecision in reliability information. Various reliability parameters are addressed for analyzing the behavior of the system and their correspondingly obtained results of the proposed approach are compared with the existing fuzzy lambda-tau technique results. The sensitivity as well as performance analysis has also been performed to explore the effect of failure/repair rates of the components on system availability. The approach has been illustrated with an example of synthesis unit of a urea fertilizer plant situated in Northern part of India. The obtained results may be helpful for the plant personnel for analyzing the systems’ behavior and to improve their performance by adopting suitable maintenance strategies.

Similar content being viewed by others

References

Ebeling C (2001) An introduction to reliability and maintainability engineering. Tata McGraw-Hill Company Ltd., New York

Garg H, Rani M, Sharma SP (2013) Predicting uncertain behavior of press unit in a paper industry using artificial bee colony and fuzzy lambda-tau methodology. Appl Soft Comput 13(4):1869–1881

Zadeh LA (1965) Fuzzy sets. Inf Control 8:338–353

Cai KY (1996) System failure engineering and fuzzy methodology: an introductory overview. Fuzzy Sets Syst 83:113–133

Cai KY, Wen CY, Zhang ML (1991) Fuzzy variables as a basis for a theory of fuzzy reliability in the possibility context. Fuzzy Sets Syst 42:145–172

Karwowski W, Mittal A (1986) Applications of fuzzy set theory in human factors. Elsevier, Amsterdam

Chen SM (1994) Fuzzy system reliability analysis using fuzzy number arithmetic operations. Fuzzy Sets Syst 64(1):31–38

Chen SM (1996) New method for fuzzy system reliability analysis. Cyber Syst Int J 27:385–401

Cheng CH, Mon DL (1993) Fuzzy system reliability analysis by interval of confidence. Fuzzy Sets Syst 56(1):29–35

Mon DL, Cheng CH (1994) Fuzzy system reliability analysis for components with different membership functions. Fuzzy Sets Syst 64(2):145–157

Singer D (1990) A fuzzy set approach to fault tree and reliability analysis. Fuzzy Sets Syst 34(2):145–155

Yao JS, Su JS, Shih TS (2008) Fuzzy system reliability analysis using triangular fuzzy numbers based on statistical data. J Inf Sci Eng 24:1521–1535

Jamkhaneh EB, Nozari A (2012) Fuzzy system reliability analysis based on confidence interval. Adv Mat Res 433–440:4908–4914

Jamkhaneh EB, Nozari A, Ghara AN (2011) Analyzing fuzzy system reliability using confidence interval. World Appl Sci J 13(10):2191–2197

Das K (2008) A comparative study of exponential distribution vs Weibull distribution in machine reliability analysis in a CMS design. Comput Indus Eng 54:12–33

Garg H (2013) Performance analysis of complex repairable industrial systems using PSO and fuzzy confidence interval based lambda-tau methodology. ISA Trans 52(2):171–183

Garg H, Sharma SP (2012) Stochastic behavior analysis of industrial systems utilizing uncertain data. ISA Trans 51(6):752–762

Knezevic J, Odoom ER (2001) Reliability modeling of repairable systems using Petri nets and fuzzy lambda-tau methodology. Reliab Eng Syst Saf 73(1):1–17

Sharma SP, Garg H (2011) Behavioral analysis of a urea decomposition system in a fertilizer plant. Int J Ind Syst Eng 8(3):271–297

Bai X, Asgarpoor S (2004) Fuzzy based approaches to substation reliability evaluation. Electr Power Syst Res 69:197–204

Pedrycz W (1994) Why triangular membership functions? Fuzzy Sets Syst 64(1):21–30

Garg H (2013) Reliability analysis of repairable systems using Petri nets and Vague lambda-tau methodology. ISA Trans 52(1):6–18

Ross TJ (2004) Fuzzy logic with engineering applications, 2nd edn. Wiley, New York

Garg H, Sharma SP (2012) Behavior analysis of synthesis unit in fertilizer plant. Int J Qual Reliab Manag 29(2):217–232

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garg, H. Analyzing the Behavior of an Industrial System Using Fuzzy Confidence Interval Based Methodology. Natl. Acad. Sci. Lett. 37, 359–370 (2014). https://doi.org/10.1007/s40009-014-0239-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40009-014-0239-2