Abstract

A phenomenological analysis on desorption mechanism of lemon essential oil in semicrystalline polymer nanocomposites is performed. Films were made of polypropylene and talc nanoparticles obtained by blown extrusion were used as a case study due to the high complexity of sorption phenomena in such systems containing a semicrystalline polymer and nucleating particles. In this sense, a systematic analysis combining both morphological effects and intrinsic properties of each component was considered. Talc characteristics, e.g., morphology, surface chemistry, oil absorption properties, mean particle size and its distribution, and impurity presence, were considered in desorption analysis. Regarding semicrystalline matrix, morphological and crystalline changes induced by talc nanoparticles and processing were included in this study. Desorption of lemon essential oil from nanocomposite films with different talc concentrations (0, 1, and 5 wt%) which have distinctive and well characterized morphologies was evaluated through gravimetric and thermogravimetric analysis. Results show that polypropylene film has a desorption rate higher than nanocomposites containing 5 wt%, but lower than those with 1 wt% talc. This behavior is a consequence of the global crystallinity configuration changes produced by nanoparticle concentration and film obtaining process. It is revealed that simplified and conventional approaches that consider tortuosity as unique effect of particle presence in nanocomposite mass transport do not allow to comprehend the desorption mechanism involved in a complex system such as the semicrystalline polymer nanocomposites. The present study gives additional insight into the complex mechanism involved in desorption of strongly swelling oil in nanocomposite films based on semicrystalline polymers and mineral nucleating particles.

Similar content being viewed by others

References

Ebnesajjad S (2013) Plastic films in food packaging: materials, technology and applications. Elsevier, Waltham

Robertson GL (2013) Food packaging: principles and practice. CRC Press, London

Arab-Tehrany E, Gonzalez LS (2015) Transfer phenomena in food/packaging system. Functional polymers in food science: from technology to biology. Wiley, New Jersey. doi:10.1002/9781119109785.ch3

Kilcast D, Subramaniam P (2000) The stability and shelf-life of food: introduction. Woodhead Publishing Ltd., Cambridge

Moreira MR, Alvarez MV, Ponce AG (2016) Essential Oils. Postharvest management approaches for maintaining quality of fresh produce. Springer, Berlin

Maisanaba S, Llana-Ruiz-Cabello M, Gutiérrez-Praena D, Pichardo S, Puerto M, Prieto AI, Jos A, Cameán AM (2016) New advances in active packaging incorporated with essential oils or their main components for food preservation. Food Rev Int. doi:10.1080/87559129.2016.1175010

Quezada Gallo JA, Debeaufort F, Voilley A (1999) Interactions between aroma and edible films. 1. Permeability of methylcellulose and low-density polyethylene films to methyl ketones. J Agric Food Chem 47:108–113

Maier C, Calafut T (1998) Polypropylene. The definitive user’s guide and databook. William Andrew Inc., Norwich

Campos-Requena VH, Rivas BL, Pérez MA, Pereira ED (2016) Short and long-term loss of carvacrol from polymer/clay nanocomposite film—a chemometric approach. Polym Int 65:483–490

Alshabanat M (2013) Characterization and mechanical properties study of intercalated talc/polypropylene nanocomposites. J Am Sci 9:322–326

Ferrage E, Martin F, Boudet A, Petit S, Fourty G, Jouffret F, Micoud P, De Parseval P, Salvi S, Bourgerette C, Ferret J, Saint-Gerard Y, Buratto S, Fortune JP (2002) Talc as nucleating agent of polypropylene: morphology induced by lamellar particle addition and interface mineral-matrix modelization. J Mater Sci 37:1561–1573

Carretero MI, Pozo M (2010) Clay and non-clay minerals in the pharmaceutical and cosmetic industries Part II. Active ingredients. Appl Clay Sci 47:171–181

Casanova H, Orrego JA, Zapata J (2007) Oil absorption of talc minerals and dispersant demand of talc mineral non-aqueous dispersions as a function of talc content: a surface chemistry approach. Colloids Surf A Physicochem Eng Asp 299:38–44

Castillo LA, Barbosa SE, Capiati NJ (2013) Surface-modified talc particles by acetoxy groups grafting: effects on mechanical properties of polypropylene/talc composites. Polym Eng Sci 53:89–95

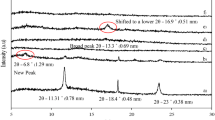

Castillo LA, Barbosa SE, Capiati NJ (2012) Influence of talc genesis and particle surface on the crystallization kinetics of polypropylene/talc composites. J Appl Polym Sci 126:1763–1772

Choudalakis G, Gotsis AD (2009) Permeability of polymer/clay nanocomposites: a review. Eur Polym J 45:967–984

Moaddeb M, Koros WJ (1995) Effect of orientation on the transport of d-limonene in polypropylene. J Appl Polym Sci 57:687–703

Gañán NA (2014) Extracción y fraccionamiento de biocidas de origen natural mediante el uso de fluidos supercríticos. Ph.D. Thesis, Universidad Nacional del Sur, Bahía Blanca, Argentina

Espinosa K, Castillo L, Barbosa S (2016) In: Grumezescu AM (ed) Nanotechnology in agri-food industry (multi-volume SET I–X) volume VII: food packaging, 1st edition, ISBN: 9780128043028. Elsevier (Academic Press), Cambridge, USA. http://store.elsevier.com/Food-Packaging/isbn-9780128043028/

Marinelli AL, Bretas RES (2003) Blends of polypropylene resins with a liquid crystalline polymer. I. Isothermal crystallization. J Appl Polym Sci 87:916–930

Rybnikář F (1989) Orientation in composite of polypropylene and talc. J Appl Polym Sci 38:1479–1490

Zaikov GE, Mikheev YA (2005) Kinetics and mechanisms of chemical reactions. Nova Science Publishers Inc, New York

Anthony Liu C-PS, Nguyen DC, Neogi P (1990) Effects of constrained chain conformations on polymer-solute interactions in semicrystalline polymers. J Macromol Sci Phys B 29:203–220

Kucera M (2013) Industrial minerals and rocks: developments in economic geology. Elsevier Science, New York, p 1984

Koshida T, Kumagai M, Hiwasa S (2015) US Patent US20150209248 A1

DeArmitt C, Hancock M (2003) In: Rothon RN (ed) Particulate-filled polymer composites. Rapra Technology Limited, Shrewsbury

Hancock M, Rothon RN (2003) In: Rothon RN (ed) Particulate-filled polymer composites. Rapra Technology Limited, Shrewsbury

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processes. Prog Polym Sci 28:1539–1641

Manias E, Polizos G, Nakajima H, Heidecker MJ (2007) In: Morgan AB, Wilkie CA (eds) Flame retardant polymer nanocomposites. Wiley-Interscience, Hoboken

Zheng XY, Ding H, Mei FL, Zhu XY, Wang MM (2012) Preparation and property characterization of talc/phthalocyanine blue composite powder. Key Eng Mat 512–515:239–244

Karacan I, Benli H (2011) An X-ray diffraction study for isotactic polypropylene fibres produced with take-up speeds of 2500–4250 m/min. Tekstil ve Konfeksiyon 21:201–209

Addink EJ, Beintema J (1961) Polymorphism of crystalline polypropylene. Polymer 2:185–193

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alonso, Y.N., Grafia, A.L., Castillo, L.A. et al. Lemon essential oil desorption from polypropylene/talc nanocomposite films. Iran Polym J 25, 999–1008 (2016). https://doi.org/10.1007/s13726-016-0485-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-016-0485-x