Abstract

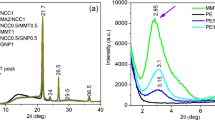

The effects of organo-modified montmorillonite (OMMT) nanoclay and epoxidized natural rubber (ENR) content on the gas barrier, tensile, and the thermal properties of nanocomposite films based on low-density polyethylene (LDPE) are investigated. Linear low-density polyethylene-grafted maleic anhydride (LLDPE-g-MA) is used as a compatibilizer to obtain better dispersion of the nanoclay in the blends. The blends, with various amounts of ENR (0–10) wt%, are melt-compounded and extruded using a blown film extrusion single screw. The tensile properties of films are studied in machine direction (MD). The gas permeability of films is studied via constant pressure and a soap bubble flow meter. The melting and crystallization behaviors of films are examined via differential scanning calorimetry (DSC). Chemical interactions of composite blends are examined via Fourier transform infrared (FTIR) spectroscopy. An addition of 6 wt% nanoclay improved the tensile modulus by about 11 %. It further reduced the oxygen permeability by about 83 %. Although introducing OMMT decreased the percentage of crystallinity (X C), the presence of LLDPE-g-MA in the nanocomposite enhanced the property due to better intercalation between the phases. Incorporation of ENR caused an increase in the Young’s modulus for compatibilized nanocomposite systems, attributed to an interaction among clay, compatibilizer, and ENR, and cross-linking effects of ENR molecules. However, ENR decreased the permeability of the film due to the ability of amorphous regions to form crystallized structures during the blown process, and cross-linking effects of ENR. In addition, ENR reduced the X C of nanocomposites due to an interference that exists in the form of ENR molecular incorporation. The FTIR spectra showed that the maleic anhydride group in LLDPE-g-MA reacted in situ with the epoxy groups of ENR, which was an evidence of grafting reaction.

Similar content being viewed by others

References

Qazvini NT, Mohammadi N, Ghaffarian SR, Assempour H, Haghighatkish M (2002) Quantitative orientational characterization of low-density polyethylene blown films By X-ray and birefringence. Iran Polym J 11:359–364

Arunvisut S, Phummanee S, Somwangthanaroj A (2007) Effect of clay on mechanical and gas barrier properties of blown film LDPE/clay nanocomposites. J Appl Polym Sci 106:2210–2217

Dadbin S, Noferesti M, Frounchi M (2008) Oxygen barrier LDPE/LLDPE/organoclay nano-composite films for food packaging. Macromol Symp 274:22–27

Singh B, Sharma N (2008) Mechanistic implications of plastic degradation. Polym Degrade Stabil 93:561–584

Durmus A, Woo M, Kasgoez A, Macosko CW, Tsapatsis M (2007) Intercalated linear low density polyethylene (LLDPE)/clay nanocomposites prepared with oxidized polyethylene as a new type compatibilizer: structural, mechanical and barrier properties. Eur Polym J 43:3737–3749

Taglialatela Scafati S, Boragno L, Losio S, Limbo S, Castellano M, Sacchi MC, Stagnaro P (2011) Modulation of barrier properties of monolayer films from blends of polyethylene with ethylene-co-norbornene. J Appl Polym Sci 121:3020–3027

Carvalho JWC, Sarantopoulos C, Innocentini-Mei LH (2010) Nanocomposites-based polyolefins as alternative to improve barrier properties. J Appl Polym Sci 118:3695–3700

Azeredo HMC (2009) Nanocomposites for food packaging applications. Food Res Int 42:1240–1253

Durmus A, Kasgoz A, Macosko CW (2008) Mechanical properties of linear low density polyethylene (LLDPE)/clay nanocomposites: estimation of aspect ratio and interfacial strength by composite models. J Macromol Sci B Phys 47:608–619

Khalili S, Masoomi M, Bagheri R (2013) The effect of organo-modified montmorillonite on mechanical and barrier properties of linear low-density polyethylene/low-density polyethylene blend films. J Plast Film Sheet 29:39–55

Razzaghi-Kashani M, Hasankhani H, Kokabi M (2007) Improvement in physical and mechanical properties of butyl rubber with montmorillonite organo-clay. Iran Polym J 16:671–679

Zhong Y, Janes D, Zheng Y, Hetzer M, De Kee D (2007) Mechanical and oxygen barrier properties of organoclay–polyethylene nanocomposite films. Polym Eng Sci 47:1101–1107

Alexandre M, Dubois P, Sun T, Garces JM, Jerome R (2002) Polyethylene-layered silicate nanocomposites prepared by the polymerization-filling technique: synthesis and mechanical properties. Polymer 43:2123–2132

Song L, Hu Y, Wang S, Chen Z, Fan W (2002) Study on the solvothermal preparation of polyethylene/organophilic montmorillonite nanocomposites. J Mater Chem 12:3152–3155

Koo CM, Ham HT, Kim SO, Wang KH, Chung IJ (2002) Morphology evolution and anisotropic phase formation of the maleated polyethylene-layered silicate nanocomposites. Macromolecules 35:5116–5122

Gopakumar TG, Lee JA, Kontopoulou M, Parent JS (2002) Influence of clay exfoliation on the physical properties of montmorillonite/polyethylene composites. Polymer 43:5483–5491

Hotta S, Paul DR (2004) Nanocomposites formed from linear low density polyethylene and organoclays. Polymer 45:7639–7654

Ranade A, Nayak K, Fairbrother D, D’Souza NA (2005) Maleated and non-maleated polyethylene-montmorillonite layered silicate blown films: creep, dispersion and crystallinity. Polymer 46:7323–7333

Azlina NH, Sahrim HA, Rozaidi R, Bahri ARS, Yamamoto Y, Kawahara S (2011) Oxygen barrier properties of new thermoplastic natural rubber nanocomposites. Polym Plast Technol Eng 50:1564–1569

Morawiec J, Pawlak A, Slouf M, Galeski A, Piorkowska E, Krasnikowa N (2005) Preparation and properties of compatibilized LDPE/organo-modified montmorillonite nanocomposites. Eur Polym J 41:1115–1122

Lee J-H, Jung D, Hong C-E, Rhee KY, Advani SG (2005) Properties of polyethylene-layered silicate nanocomposites prepared by melt intercalation with a PP-g-MA compatibilizer. Composites Sci Technol 65:1996–2002

Supri AG, Salmah H, Hazwan K (2008) Low density polyethylene-nanoclay composites: the effect of poly(acrylic acid) on mechanical properties, XRD, morphology properties and water absorption. Malay Polym J MPJ 3:39–53

Malucelli G, Ronchetti S, Lak N, Priola A, Dintcheva NT, La Mantia FP (2007) Intercalation effects in LDPE/o-montmorillonites nanocomposites. Eur Polym J 43:328–335

Goritz D, Horst Muller F, Sietz W (1977) Temperature induced and stress—induced crystallization in oriented polymers. In: Fischer EW, Horst Müller F, Kausch HH (eds) Mehrphasige Polymersysteme, vol 62. Progress in Colloid and Polymer Science, Steinkopff, pp 114-116

Mahapram S, Poompradub S (2011) Preparation of natural rubber (NR) latex/low density polyethylene (LDPE) blown film and its properties. Polym Test 30:716–725

Yikmis M, Steinbüchel A (2012) Historical and recent achievements in the field of microbial degradation of natural and synthetic rubber. Appl Environ Microbiol 78:4543–4551

Mooibroek H, Cornish K (2000) Alternative sources of natural rubber. Appl Microbiol Biotechnol 53:355–365

Kalkornsurapranee E, Vennemann N, Kummerlowe C, Nakason C (2012) Novel thermoplastic natural rubber based on thermoplastic polyurethane blends: influence of modified natural rubbers on properties of the blends. Iran Polym J 21:689–700

Pichaiyut S, Nakason C, Vennemann N (2012) Thermoplastic elastomers-based natural rubber and thermoplastic polyurethane blends. Iran Polym J 21:65–79

Ahmad I, Fern LP (2006) Effect of PE-g-MA compatibilizer on the morphology and mechanical properties of 70/30 HDPE/ENR blends. Polym Plast Technol Eng 45:735–739

Nakason C, Jarnthong M, Kaesaman A, Kiatkamjornwong S (2008) Thermoplastic elastomers based on epoxidized natural rubber and high-density polyethylene blends: effect of blend compatibilizers on the mechanical and morphological properties. J Appl Polym Sci 109:2694–2702

Nakason C, Wannavilai P, Kaesaman A (2006) Thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends:effect of epoxide levels in ENR molecules. J Appl Polym Sci 101:3046–3052

Nakason C, Wannavilai P, Kaesaman A (2006) Thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends: effect of compatibilizers and reactive blending. J Appl Polym Sci 100:4729–4740

Sam ST, Ismail H, Ahmad Z (2010) Effect of epoxidized natural rubber on the processing behavior, tensile properties, morphology, and thermal properties of linear-low-density polyethylene/soya powder blends. J Vinyl Add Technol 16:238–245

Chapman AV (2007) Natural rubber and NR-based polymers: renewable materials with unique properties. Paper presented at the 24th Int H.F. Mark-Symposium. ‘Advances in the Field of Elastomers & Thermoplastic Elastomers’, Vienna, 15-16 November

Nampitch T, Magaraphan R (2011) Preparation, characterization and properties of ternary blends with epoxidized natural rubber, poly (lactic acid) and poly (butylene adipate-co-terephthalate). Adv Mat Res 335–336:762–768

Khonakdar HA, Morshedian J, Mehrabzadeh M, Wagenknecht U, Jafari SH (2003) Thermal and shrinkage behaviour of stretched peroxide crosslinked high-density polyethylene. Eur Polym J 39:1729–1734

Persico P, Ambrogi V, Carfagna C, Cerruti P, Ferrocino I, Mauriello G (2009) Nanocomposite polymer films containing carvacrol for antimicrobial active packaging. Polym Eng Sci 49:1447–1455

Mehrabzadeh M, Kamal MR, Quintanar G (2009) Maleic anhydride grafting onto HDPE by in situ reactive extrusion and its effect on intercalation and mechanical properties of HDPE/clay nanocomposites. Iran Polym J 18:833–842

Naderi G, Lafleur PG, Dubois C (2007) Dynamically vulcanized nanocomposite thermoplastic elastomers based on EPDM/PP (rheology and morphology). Int Polym Proc 22:284–292

Kim DH, Fasulo PD, Rodgers WR, Paul DR (2007) Effect of the ratio of maleated polypropylene to organoclay on the structure and properties of TPO-based nanocomposites. Part I: morphology and mechanical properties. Polymer 48:5960–5978

Razmjooei F, Naderi G, Bakhshandeh G (2012) Preparation of dynamically vulcanized thermoplastic elastomer nanocomposites based on LLDPE/reclaimed rubber. J Appl Polym Sci 124:4864–4873

Wang SF, Hu Y, Qu ZK, Wang ZZ, Chen ZY, Fan WC (2003) Preparation and flammability properties of polyethylene/clay nanocomposites by melt intercalation method from Na+ montmorillonite. Mater Lett 57:2675–2678

Cho TW, Kim SW (2011) Morphologies and properties of nanocomposite films based on a biodegradable poly(Ester)urethane elastomer. J Appl Polym Sci 121:1622–1630

Jaafar J, Ismail AF, Matsuura T (2009) Preparation and barrier properties of SPEEK/Cloisite 15A (R)/TAP nanocomposite membrane for DMFC application. J Membr Sci 345:119–127

Mittal V (2008) Mechanical and gas permeation properties of compatibilized polypropylene-layered silicate nanocomposites. J Appl Polym Sci 107:1350–1361

Ugel E, Giuliano G, Modesti M (2011) Poly(ethylene-co-vinyl acetate)/clay nanocomposites: effect of clay nature and compatibilising agents on morphological thermal and mechanical properties. Soft Nanosci Lett 1:105–119

Zhang L, Wan C, Zhang Y (2009) Investigation on morphology and mechanical properties of polyamide 6/maleated ethylene-propylene-diene rubber/organoclay composites. Polym Eng Sci 49:209–216

Chiu FC, Lai SM, Chen YL, Lee TH (2005) Investigation on the polyamide 6/organoclay nanocomposites with or without a maleated polyolefin elastomer as a toughener. Polymer 46:11600–11609

Wahit MU, Hassan A, Ishak ZAM, Czigany T (2009) Ethylene-octene copolymer (POE) toughened polyamide 6/polypropylene nanocomposites: effect of POE maleation. Express Polym Lett 3:309–319

Balakrishnan H, Nematzadeh N, Wahit MU, Hassan A, Imran M (2012) Epoxidized natural rubber toughened polyamide6/organically modified montmorillonite nanocomposites. J Thermoplast Compos Mater 26:1–18

Kilwon C, Fengkui L, Jaesung C (1999) Crystallization and melting behaviour of blends polypropylene and maleated polypropylene blends. Polymer 40:1719–1729

Dahlan HM, Zaman MDK, Ibrahim A (2002) The morphology and thermal properties of liquid natural rubber (LNR)-compatibilized 60/40 NR/LLDPE blends. Polym Test 21:905–911

Ismaeel MA, Azman H (2013) The effects of magnesium oxide on the thermal, morphological, and crystallinity properties of metallocene linear low-density polyethylene/rubbers composite. J Polym Eng 33:229–238

Tjong SC, Bao SP, Liang GD (2005) Polypropylene/montmorillonite nanocomposites toughened with SEBS-g-MA: structure-property relationship. J Polym Sci B Polym Phys 43:3112–3126

Nakason C, Saiwari S, Kaesaman A (2006) Rheological properties of maleated natural rubber/polypropylene blends with phenolic modified polypropylene and polypropylene-g-maleic anhydride compatibilizers. Polym Test 25:413–423

Nakason C, Kaesaman A, Supasanthitikul P (2004) The grafting of maleic anhydride onto natural rubber. Polym Test 23:35–41

Silvestre C, Duraccio D, Cimmino S (2011) Food packaging based on polymer nanomaterials. Prog Polym Sci 36:1766–1782

Chinellato AC, Vidotti SE, Hu GH, Pessan LA (2010) Compatibilizing effect of acrylic acid modified polypropylene on the morphology and permeability properties of polypropylene/organoclay nanocomposites. Composite Sci Technol 70:458–465

Tosaka M, Murakami S, Poompradub S, Kohjiya S (2004) Orientation and crystallization of natural rubber network as revealed by WAXD using synchrotron radiation. Macromolecules 37:3299–3309

Acknowledgments

The authors would like to acknowledge the Universiti Teknologi Malaysia (UTM) for providing facilities and equipment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Attaran, S.A., Hassan, A. & Wahit, M.U. Effects of ENR and OMMT on barrier and tensile properties of LDPE nanocomposite film. Iran Polym J 24, 367–378 (2015). https://doi.org/10.1007/s13726-015-0329-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0329-0