Abstract

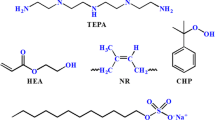

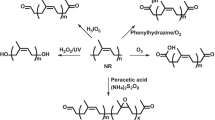

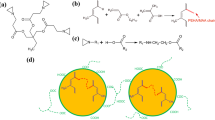

Natural rubber, one of the widely used renewable resources, is susceptible to degradation upon exposure to sunlight, oxygen, heat and ozone due to the presence of double bonds in cis-polyisoprene. This work describes a versatile means to improve the stability of natural rubber by saturating the double bonds through grafting and hydrogenation reactions as a one-pot method. Graft copolymerization of methyl methacrylate onto natural rubber latex was carried out using emulsion polymerization in the presence of cumene hydroperoxide/tetra-ethylene pentamine mixture as initiator whereas hydrogenation of the natural rubber was performed using the diimide reduction method. The effects of initiator concentration, monomer concentration, reaction temperature, and reaction time on reaction efficiency were investigated. In addition, the thermal, mechanical, ozone ageing, and solvent resistance properties of modified natural rubbers were characterized and found to be superior to the unmodified natural rubber. The decomposition temperature of the grafted-hydrogenated natural rubber is almost 30 °C better than that of the unmodified rubber. The mechanical strength was also improved. In order to test the versatility of this one-pot technique, styrene was also used as a monomer to graft onto the natural rubber. These results show that the one-pot method developed in this work is a simple, versatile means for improving the chemical and physical properties of the natural rubber. This work is also a proof-of-concept for other combinations of reactions or other polymers.

Similar content being viewed by others

References

Graves DF (2007) Rubber. In: Kent JA (ed) Handbook of industrial chemistry and biotechnology. Springer, US, pp 689–718

Gamlin C, Markovic MG, Dutta NK, Choudhury NR, Matisons JG (2000) Structural effects on the decomposition kinetics of EPDM elastomers by high-resolution TGA and modulated TGA. J Therm Anal Calorim 59:319–336

dos Santos KAM, Suarez PAZ, Rubim JC (2005) Photo-degradation of synthetic and natural polyisoprenes at specific UV radiations. Polym Degrad Stab 90:34–43

Chaikumpollert O, Sae-Heng K, Wakisaka O, Mase A, Yamamoto Y, Kawahara S (2011) Low temperature degradation and characterization of natural rubber. Polym Degrad Stab 96:1989–1995

Hinchiranan N, Charmondusit K, Prasassarakich P, Rempel GL (2006) Hydrogenation of synthetic cis-1,4-polyisoprene and natural rubber catalyzed by [Ir(COD)py(PCy3)]PF6. J Appl Polym Sci 100:4219–4233

Kongparakul S, Prasassarakich P, Rempel GL (2008) Effect of grafted methyl methacrylate on the catalytic hydrogenation of natural rubber. Eur Polym J 44:1915–1920

Radabutra S, Thanawan S, Amornsakchai T (2009) Chlorination and characterization of natural rubber and its adhesion to nitrile rubber. Eur Polym J 45:2017–2022

Zhong JP, Li SD, Wei YC, Peng Z, Yu HP (1999) Study on preparation of chlorinated natural rubber from latex and its thermal stability. J Appl Polym Sci 73:2863–2867

Xue X, Wu Y, Wang F, Ling J, Fu X (2010) Preparation and thermal stability of brominated natural rubber from latex. J Appl Polym Sci 118:25–29

Lewis C, Bunyung S, Kiatkamjornwong S (2003) Rheological properties and compatibility of NR/EPDM and NR/brominated EPDM blends. J Appl Polym Sci 89:837–847

Kado N, Patjaree S, Akabori K, Yamamoto Y, Kawahara S (2012) A novel proton conductive polymer electrolyte prepared from natural rubber. Kobunshi Ronbunshu 69:228–234

Xavier T, Samuel J, Manjooran KB, Kurian T (2002) New ionic polymer: synthesis and properties of “zinc sulfonated natural rubber”. J Elastomers Plast 34:91–101

Satraphan P, Intasiri A, Tangpasuthadol V, Kiatkamjornwong S (2009) Effects of methyl methacrylate grafting and in situ silica particle formation on the morphology and mechanical properties of natural rubber composite films. Polym Adv Technol 20:473–486

Suksawad P, Yamamoto Y, Kawahara S (2011) Preparation of thermoplastic elastomer from natural rubber grafted with polystyrene. Eur Polym J 47:330–337

Mahittikul A, Prasassarakich P, Rempel GL (2007) Diimide hydrogenation of natural rubber latex. J Appl Polym Sci 105:1188–1199

Arayapranee W, Rempel GL (2009) Synthesis and mechanical properties of diimide-hydrogenated natural rubber vulcanizates. J Appl Polym Sci 114:4066–4075

Simma K, Rempel GL, Prasassarakich P (2009) Improving thermal and ozone stability of skim natural rubber by diimide reduction. Polym Degrad Stab 94:1914–1923

Radabutra S, Thanawan S, Amornsakchai T (2009) Chlorination and characterization of natural rubber and its adhesion to nitrile rubber. Eur Polym J 45:2017–2022

H-p Yu, S-d Li, Zhong JP, Xu K (2004) Studies of thermooxidative degradation process of chlorinated natural rubber from latex. Thermochim Acta 410:119–124

Suksawad P, Kosugi K, Yamamoto Y, Akabori K, Kuroda H, Kawahara S (2011) Polymer electrolyte membrane with nanomatrix channel prepared by sulfonation of natural rubber grafted with polystyrene. J Appl Polym Sci 122:2403–2414

El Sayed AM (2007) Evaluation of new conducting polymeric membrane based on sulfonation of compatibilized NR/EPDM blend. J Appl Polym Sci 104:3804–3812

Kochthongrasamee T, Prasassarakich P, Kiatkamjornwong S (2006) Effects of redox initiator on graft copolymerization of methyl methacrylate onto natural rubber. J Appl Polym Sci 101:2587–2601

Zhang S, Cao L, Shao F, Chen L, Jiao J, Gao W (2008) Grafting of methyl methacrylate onto natural rubber in supercritical carbon dioxide. Polym Adv Technol 19:54–59

Arayapranee W, Rempel GL (2008) Morphology and mechanical properties of natural rubber and styrene-grafted natural rubber latex compounds. J Appl Polym Sci 109:1395–1402

Pukkate N, Kitai T, Yamamoto Y, Kawazura T, Sakdapipanich J, Kawahara S (2007) Nano-matrix structure formed by graft-copolymerization of styrene onto natural rubber. Eur Polym J 43:3208–3214

Amnuaypanich S, Ratpolsan P (2009) Pervaporation membranes from natural rubber latex grafted with poly(2-hydroxyethyl methacrylate) (NR-g-PHEMA) for the separation of water-acetone mixtures. J Appl Polym Sci 113:3313–3321

Nakason C, Kaesaman A, Supasanthitikul P (2004) The grafting of maleic anhydride onto natural rubber. Polym Test 23:35–41

Arayapranee W, Prasassarakich P, Rempel GL (2004) Blends of poly(vinyl chloride) PVQ/natural rubber-g-(styrene-co-methyl methacrylate) for improved impact resistance of PVC. J Appl Polym Sci 93:1666–1672

Afifi H, El-Wakil AA (2008) Study of the effect of natural rubber-graft-maleic anhydride (NR-g-MA) on the compatibility of NR-NBR blends using the ultrasonic technique. Polym-Plast Technol Eng 47:1032–1039

Pisuttisap A, Hinchiranan N, Rempel GL, Prasassarakich P (2013) ABS modified with hydrogenated polystyrene-grafted-natural rubber. J Appl Polym Sci 129:94–104

Kangwansupamonkon W, Gilbert RG, Kiatkamjornwong S (2005) Modification of natural rubber by grafting with hydrophilic vinyl monomers. Macromol Chem Phys 206:2450–2460

Juntuek P, Ruksakulpiwat C, Chumsamrong P, Ruksakulpiwat Y (2011) Glycidyl methacrylate grafted natural rubber: synthesis, characterization, and mechanical property. J Appl Polym Sci 122:3152–3159

Acknowledgments

This work is funded by the 2013 Science & Technology Research Grant by the Thailand Toray Science Foundation. The authors acknowledge the Department of Chemistry, Faculty of Science and Technology, Thammasat University. In addition, the authors would like to thank the reviewers and journal editors for useful comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kookarinrat, C., Paoprasert, P. Versatile one-pot synthesis of grafted-hydrogenated natural rubber. Iran Polym J 24, 123–133 (2015). https://doi.org/10.1007/s13726-014-0306-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-014-0306-z