Abstract

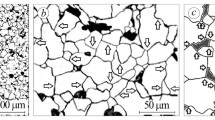

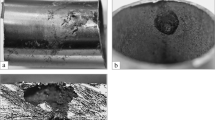

Various steel grades used in the piping system of a waste heat recovery system at a petrochemical plant producing hydrogen by the steam–methane process are shown to be degraded by different modes. Pipes made of low-alloy steel (grade C-1/2Mo) have developed two problems: (1) pitting and formation of a blackish powdery deposit at the internal surface of the pipe adjacent to the inlet of the reboiler, and (2) an oxide at the internal surface of the bypass pipe fitted into a 304 stainless steel pipe. Furthermore, a welded elbow made of 304 stainless steel has developed a crack in the weld seam by a fatigue mechanism. Although the results suggest that metal dusting may be related to leakage of the reformed carbonaceous gas into the piping system, a steel resistant to metal dusting with a composition defined by %Cr + 2%Si > 24 wt% may be considered for the application. On the other hand, a steel with better fatigue resistance such as one with a tempered martensitic structure may be considered as a replacement for the 304 stainless steel.

Similar content being viewed by others

References

L. Garverick, Corrosion in the Petrochemical Industry (ASM International, Materials Park, 2011)

E. Martelli, L.O. Nord, O. Bolland, Design criteria and optimization of heat recovery steam cycles for integrated reforming combined cycles with CO2 capture. Appl. Energy 92, 255–268 (2012)

V. Ganapathy, Industrial Boilers and Heat Recovery Steam Generators: Design, Applications and Calculations (Marcel Dekker, New York, 2003)

A. Steinfeld, Overview of hydrogen production, in Handbook of Hydrogen Energy, ed. by S.A. Sherif, D.Y. Goswami, E.K. Stefanakos, A. Steinfeld (CRC, Boca Raton, 2014), p. 19

G.Y. Lai, High Temperature Corrosion and Materials Applications (ASM International, Materials Park, 2007)

H.J. Grabke, Corrosion by Carbon and Nitrogen: Metal Dusting, Carburization and Nitridation (CRC, New York, 2007)

M. Szkodo, G. Gajowiec, Studies of the mechanism of metal dusting of 10CrMo9-10 steel after 10 years of operation in the semi-regenerative catalytic reformer. Corros. Sci. 102, 279–290 (2016)

H.M. Tawancy, Degradation of C-1/2Mo steel pipe by metal dusting in a steam reforming process. J. Fail. Anal. Prev. 13, 643–650 (2013)

H.J. Grabke, Metal dusting. Mater. Corros. 54, 736–764 (2003)

H.J. Grabke, E.M. Muller-Lorenz, A. Schneidem, Review: Metal dusting on iron. ISU Int. 41, s1–s8 (2001)

H.M. Tawancy, Correlation between resistance to oxidation and resistance to carburization of selected high-temperature alloys. Oxid. Met. 83, 417–440 (2014)

A. Hascalik, E. Unal, N. Ozdemir, Fatigue behavior of AISI 304 steel to AISI 4340 steel welded by friction welding. J. Mater. Sci. 41, 3233–3239 (2006)

B. Boardman, Fatigue resistance of steels, ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High Performance Alloys (ASM International, Materials Park, 1990), p. 673

Acknowledgment

It is pleasure to acknowledge the continued support provided by King Fahd University of Petroleum and Minerals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tawancy, H.M. On the Degradation Modes of Various Steel Grades Used in Heat Recovery Systems: An Application from the Petrochemical Industry. Metallogr. Microstruct. Anal. 6, 36–43 (2017). https://doi.org/10.1007/s13632-016-0329-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-016-0329-2