Abstract

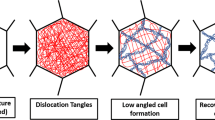

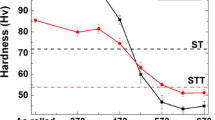

Microstructural evolution, precipitation sequence, and fracture toughness of cryorolled Al 2014 alloy subjected to annealing treatment were investigated in the present work. Al 2014 alloy was solutionized (ST) and subjected to cryorolling (CR) up to effective true strain of 2.3. The CR Al 2014 alloy samples were annealed (AN) at temperatures ranging from 100 to 350 °C for the duration of 45 min. TEM and XRD studies of the CR and CR + AN were made to understand its precipitation kinetics. Fracture toughness tests were performed on CR and CR + AN alloy, and its deformation behavior was correlated with microstructural features. The improvement in fracture toughness K ee (23.06–37.8 MPa √m) of CR Al 2014 alloy was observed as compared to ST alloy. The fracture toughness was retained up to 200 °C for CR alloy, but it started decreasing beyond 200 °C. The improvement in fracture toughness of cryorolled Al 2014 alloy at low-temperature annealing from 100 to 200 °C is attributed to the formation of GP zones and metastable phase θ′. However, beyond temperature 200 °C, fracture toughness has reduced due to combined effect of recovery, recrystallization, and formation of stable coarser phase such as θ and λ.

Similar content being viewed by others

References

M. Gavgali, B. Aksakal, Effects of various homogenisation treatments on the hot workability of ingot aluminium alloy AA2014. Mater. Sci. Eng. A 254(1), 189–199 (1998)

E.A. Starke, J.T. Staley, Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 32(2), 131–172 (1996)

Y.S.D. Shenglong, A glimpse at the development and application of aluminum alloys in aviation industry. Mater. Rev. 2, 022 (2005)

J. Mao, S.B. Kang, J.O. Park, Grain refinement, thermal stability and tensile properties of 2024 aluminum alloy after equal-channel angular pressing. J. Mater. Process. Technol. 159(3), 314–320 (2005)

S.K. Varma, D. Salas, E. Corral, E. Esquivel, K.K. Chawla, R. Mahaptra, Microstructural development during aging of 2014 aluminum alloy composite. J. Mater. Sci. 34(8), 1855–1863 (1999)

Y. Estrin, A. Vinogradov, Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61(3), 782–817 (2013)

R.B. Figueiredo, T.G. Langdon, Using severe plastic deformation for the processing of advanced engineering materials. Mater. Trans. 50(7), 1613–1619 (2009)

V.M. Segal, Severe plastic deformation: simple shear versus pure shear. Mater. Sci. Eng. A 338(1), 331–344 (2002)

Y. Saito, H. Utsunomiya, N. Tsuji, T. Sakai, Novel ultra-high straining process for bulk materials -development of the accumulative roll-bonding (ARB) process. Acta Mater. 47, 579–583 (1999)

A.P. Zhilyaev, T.G. Langdon, Using high-pressure torsion for metal processing: fundamentals and applications. Prog. Mater. Sci. 53(6), 893–979 (2008)

J.Y. Huang, Y.T. Zhu, H. Jiang, T.C. Lowe, Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater. 49(9), 1497–1505 (2001)

R.Z. Valiev, I.V. Alexandrov, R.K. Islamgaliev, Processing and properties of nanostructured materials prepared by severe plastic deformation, in Nanostructured Materials, ed. by G. Chow, N.I. Noskova (Springer, Berlin, 1998), pp. 121–142

S.K. Panigrahi, R. Jayaganthan, V. Pancholi, Effect of plastic deformation conditions on microstructural characteristics and mechanical properties of Al 6063 alloy. Mater. Des. 30(6), 1894–1901 (2009)

S.K. Panigrahi, R. Jayaganthan, V. Chawla, Effect of cryorolling on microstructure of Al–Mg–Si alloy. Mater. Lett. 62(17), 2626–2629 (2008)

N. Rangaraju, T. Raghuram, B.V. Krishna, K.P. Rao, P. Venugopal, Effect of cryo-rolling and annealing on microstructure and properties of commercially pure aluminium. Mater. Sci. Eng. A 398, 246–251 (2005)

Y. Wang, M. Chen, F. Zhou, E. Ma, High tensile ductility in a nanostructured metal. Nature 419, 912–915 (2002)

P.N. Rao, D. Singh, R. Jayaganthan, Effect of annealing on microstructure and mechanical properties of Al 6061 alloy processed by cryorolling. Mater. Sci. Technol. 29(1), 76–82 (2013)

S.K. Panigrahi, R. Jayaganthan, Development of ultrafine grained Al–Mg–Si alloy with enhanced strength and ductility. J. Alloys Compd. 470(1), 285–288 (2009)

S.K. Panigrahi, R. Jayaganthan, A comparative study on mechanical properties of Al 7075 alloy processed by rolling at cryogenic temperature and room temperature. Mater. Sci. Forum 584, 734–740 (2008)

S.K. Panigrahi, R. Jayaganthan, Development of ultrafine grained high strength age hardenable Al 7075 alloy by cryorolling. Mater. Des. 32(6), 3150–3160 (2011)

D. Singh, P.N. Rao, R. Jayaganthan, Microstructures and impact toughness behavior of Al 5083 alloy processed by cryorolling and afterwards annealing. Int. J. Min. Metall. Mater. 20(8), 759–769 (2013)

T. Shanmugasundaram, B.S. Murty, V.S. Sarma, Development of ultrafine grained high strength Al–Cu alloy by cryorolling. Scr. Mater. 54, 2013–2017 (2006)

A. Hohenwarter, R. Pippan, Fracture toughness evaluation of ultrafine-grained nickel. Scr. Mater. 64, 982–985 (2011)

A. Hohenwarter, R. Pippan, Anisotropic fracture behavior of ultrafine-grained iron. Mater. Sci. Eng. A 527(10), 2649–2656 (2010)

M. Li, D. Guo, T. Ma, G. Zhang, Y. Shi, X. Zhang, High fracture toughness in a hierarchical nanostructured zirconium. Mater. Sci. Eng. A 606, 330–333 (2014)

H. Darban, B. Mohammadi, F. Djavanroodi, Effect of equal channel angular pressing on fracture toughness of Al-7075. Eng. Fail. Anal. 65, 1–10 (2016)

P. Das, R. Jayaganthan, T. Chowdhury, I. Singh, Improvement of fracture toughness (K1c) of 7075 Al alloy by cryorolling process. Mater. Sci. Forum 683, 81–94 (2011)

C.C. Koch, Optimization of strength and ductility in nanocrystalline and ultrafine grained metals. Scr. Mater. 49(7), 657–662 (2003)

S.K. Panigrahi, R. Jayaganthan, Effect of annealing on thermal stability, precipitate evolution, and mechanical properties of cryorolled Al 7075 Alloy. Metall. Mater. Trans. A 42(10), 3208–3217 (2011)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, Influence of annealing on stain hardening behaviour and fracture properties of a cryorolled Al 2014 alloy. Mater. Sci. Eng. A 645, 383–392 (2015)

A. Rollett, F.J. Humphreys, G.S. Rohrer, M. Hatherly, Recrystallization and Related Annealing Phenomena (Elsevier, Pergamon, 2004)

A. Hohenwarter, R. Pippan, An overview on the fracture behavior of metals processed by high pressure torsion. Mater. Sci. Forum 667, 671–676 (2010)

W.F. Brown, Review of Developments in Plane Strain Fracture Toughness Testing, vol. 463 (ASTM International, West Conshohocken, 1970)

T.L. Anderson, T.L. Anderson, Fracture Mechanics: Fundamentals and Applications (CRC Press, Boca Raton, 2005)

D. Broek, Elementary Engineering Fracture Mechanics (Springer, Berin, 2012)

F.I. Baratta, L.M. Barker. Comparisons of fracture toughness measurements by the short rod and ASTM standard method of test for plane-strain fracture toughness of metallic materials (E 399-78). J. Test. Eval. 8(3) 97-102(1980)

E.B. Tochaee, H.R.M. Hosseini, S.M.S. Reihani, On the fracture toughness behavior of in-situ Al–Ti composites produced via mechanical alloying and hot extrusion. J. Alloys Compd. 681, 12–21 (2016)

A. E992, Standard practice for determination of a fracture toughness of steels using equivalent energy methodology (1984)

J.R. Rice, A path independent integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 35(2), 379–386 (1968)

E.E. Gdoutos, Fracture Mechanics: An Introduction, vol. 123 (Springer, Berlin, 2006)

G.H.B. Donato, C. Ruggieri. Estimation procedures for J and CTOD fracture parameters using three-point bend specimens. in International Pipeline Conference (American Society of Mechanical Engineers, 2006)

C.P. Harper, Effect of alumina particle additions on the aging kinetics of 2014-aluminum matrix composites (1991)

P. Bassani, E. Gariboldi, G. Vimercati, Calorimetric analyses on aged Al–4.4Cu–0.5Mg–0.9Si–0.8Mn alloy (AA2014 grade). J. Therm. Anal. Calorim. 87(1), 247–253 (2007)

S. Abis, M. Massazza, P. Mengucci, G. Riontino, Early ageing mechanisms in a high-copper AlCuMg alloy. Scr. Mater. 45(6), 685–691 (2001)

D.J. Chakrabarti, D.E. Laughlin, Phase relations and precipitation in Al–Mg–Si alloys with Cu additions. Prog. Mater. Sci. 49(3), 389–410 (2004)

I. Dutta, C.P. Harper, G. Dutta, Role of Al2O3 particulate reinforcements on precipitation in 2014 Al-matrix composites. Metall. Mater. Trans. A 25(8), 1591–1602 (1994)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment. J. Alloys Compd. 649, 229–238 (2015)

G.E. Dieter, Mechanical Metallurgy 2nd edn. (McGraw-Hill, New York, NY, 1976)

ASM Handbook, Volume 12: Fractography (2nd printing) (ASM International, Materials Park, 1987), p. 2217

B. Li, X. Wang, H. Chen, J. Hu, C. Huang, G. Gou, Influence of heat treatment on the strength and fracture toughness of 7N01 aluminum alloy. J. Alloys Compd. 678, 160–166 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joshi, A., Yogesha, K.K., Kumar, N. et al. Influence of Annealing on Microstructural Evolution, Precipitation Sequence, and Fracture Toughness of Cryorolled Al–Cu–Si Alloy. Metallogr. Microstruct. Anal. 5, 540–556 (2016). https://doi.org/10.1007/s13632-016-0313-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-016-0313-x