Abstract

This paper presents an unconventional etching technique to reveal the microstructure in a hypoeutectic lamellar graphite iron that has been quenched after isothermal heat treatment in the proeutectic semi-solid temperature region. A technique for quantifying the dendrite microstructure using the aforementioned etching technique involving a combination of a raster graphics editor and an image analysis software is outlined. The agreement between this quantification technique with regard to volume fraction and surface area per unit volume of the dendritic austenite and corresponding point counting and line intercept techniques is analyzed. The etching technique was found useful but sporadic tinting of martensite was problematic. Some measurements showed significant systematic disagreement which correlated with the coarseness of the measured dendrites. Most systematic disagreement is attributed to difficulties in defining the dendrite boundary in the analogues and much of the random disagreement to easily identified discrepancies between the analogue and the micrograph.

Similar content being viewed by others

Introduction

Austenite Dendrites

It has been noted that free austenite (γ) solidifies as dendrites to some extent in all commercial cast irons, for a wide range of carbon equivalents and regardless of type and shape of the carbon-rich phase [1, 2]. As solidification proceeds, the γ-dendrite structure in graphitic irons becomes enveloped by eutectic colonies of γ and graphite in which the γ has the same crystallographic orientation as the prior γ-dendrites [3]. Moreover, at a lower temperature, the austenite undergoes a solid-state transformation into, e.g., ferrite (α) or pearlite, leaving few traces of the original dendritic microstructure behind. It is likely the lack of visibility of the γ-dendrites using the most widely used characterization techniques that is the main reason why this part of the microstructure is so seldom considered by practitioners and researchers. There are however strong indications that the γ-dendrite structure plays a more important role than given credit for. Elmquist et al. showed that shrinkage porosities in two different lamellar graphite iron (LGI) cylinder heads from different foundries both were connected to locations of the casting surface that featured prolonged solidification time [4]. Lab experiments designed to reproduce these conditions resulted in defects of similar character and indicated that the columnar zone of the γ-dendrites was thinner in the afflicted location leading to increased permeability and that the defects appeared to follow the γ-dendrite grain boundaries inside the casting [5]. Furthermore, research on the dynamic ripening of the γ-dendrite microstructure suggests that prolonged solidification time of such zones leads to significantly coarser γ-dendrite microstructure which further increases permeability [6]. Fourlakidis et al. presented results that indicate that also the ultimate tensile strength is closely related to the shape of the interdendritic space [7]. These discoveries show that there is great potential for improvements in learning more about the dendritic network and that a prerequisite for this is the knowledge of means of studying the γ-dendrite micro- and macrostructure.

Dendritic Austenite in As-cast Graphite Irons

The γ-dendrites can be quite visible in cast irons where the interdendritic matrix features microstructure that is easily distinguished from that of the γ-dendrites, such is the case for white iron or in graphitic irons featuring undercooled graphite. Viewing the dendrites in graphitic cast irons is more complicated, but a number of techniques have been attempted with varying results. Loper et al. [8] etched the specimen with ammonium persulfate followed by brief repolishing; however, the authors only use the technique for a qualitative investigation of the macrostructure using photomacrographs with oblique illumination. They emphasize that a constant extent of the repolishing must be employed for comparable results, indicating the level of polishing is crucial for the apparent amount or morphology of the dendrites. Motz developed a selective color etching technique for as-cast ductile irons that tints the cast iron microstructure on the basis of silicon concentration which has proven to reveal the earlier γ microstructure [9]. Boutorabi and Campbell [10] later present a similar Picric-based reagent for the same purpose that is applied to both Si and Al alloyed ductile iron; however, it appears less frequent in subsequent literature than Motz’s reagent. Rivera, Boeri and Sikora [11] conclude after a quantitative comparison that Motz’s reagent more effectively reveals the early microstructure in ductile iron than both etching with a 2% Nital solution and a heat tinting technique. However, Motz’s reagent has some known setbacks, the most immediate being that it is based on Picric acid which is toxic and potentially explosive. A more practical setback is the difficulties in achieving a uniform and reproducible coloring. Factors like the temperature, the fading effect of the reagent, evaporation of the solvent and the freshness, and cleanliness of the polished surface influence the required duration of the treatment, and the difference between ideal coloring and over-etching can be a matter of seconds. This is further complicated by the specimen being tinted by immersion in the reagent which is practically opaque, meaning that evaluating the result of the etching demands that the etching process is interrupted and the specimen is washed and dried. In case of over- or under-etching, the specimen is repolished and the procedure is started over; however, some success has been reported in resuming the etching in case of under-etching, allowing for step-wise etching until the result is satisfactory [12]. Also, despite a good coloring, some difficulties in measuring the dendrites remain. In as-cast irons, large portions of the dendritic network are commonly obscured by eutectic cells due to their similar silicon concentration. The low reproducibility and non-uniformity of the coloring make the use of conventional color-based image analysis on the raw micrographs difficult. Nevertheless, with this tool at their disposal, cast iron researchers have begun exploring the nature and role of the early microstructure of LGI, CGI, and SGI [4, 6, 11, 13, 14]. Some have started looking into research done on other materials where the dendritic structure has already been studied for decades and have attempted to extend the knowledge to cast iron. Several parameters related to the characteristics of the dendritic structures have been adopted [6], and researchers have begun exploring relations between these parameters and the properties of the material [7]. The technique has also been applied to produce 3D reconstructions of a portion of the dendritic network [15].

γ-Dendrites in Interrupted Gray Irons

The dendritic structure in as-cast irons as revealed using Motz’s reagent does however not necessarily closely resemble the dendritic structure as it was during the earlier stage of solidification, because it is under normal casting conditions extensively ripened [6]. A technique to circumvent this problem is interrupted solidification which relies on promoting white solidification of the interdendritic volume by rapidly quenching the material from a semi-solid state [2, 16]. This technique has played an important role in the studies of solidification of cast irons. Motz’s reagent has also here proven useful, and other similar reagents based on picric acid have also been applied to reveal the early microstructure [17]. However, the same problems of achieving reproducibility and uniformity of the coloring are present for interrupted as for as-cast irons, interfering with the conventional color-based digital image analysis. A solution to this problem has been to assist the image analysis software by producing a more easily interpreted analogue of the microstructure using a raster graphics editor by manually painting over what appears to be dendrites on the micrographs with a single color. It has been reported that a relatively large area must be analyzed to accurately measure the fraction γ-dendrites [15] so this approach can become impractical. Exploration of new techniques for revealing and quantifying the γ-dendrite microstructure in interrupted cast irons is therefore warranted. An early study employing interrupted solidification shows success in revealing the dendritic network in interrupted cast iron using “strong etch” (presumably prolonged Nital etching) [16], producing a contrast between the etched dendrites and the unetched Fe3C. Beraha’s Selenic acid [18] on the other hand tints the Fe3C of the quench ledeburite while leaving the dendrites mostly untouched. However, using any etching technique other than Motz’s reagent for quantification of the dendritic austenite, microstructure with respect to shape independent parameters like volume fraction and surface area per unit volume is to the knowledge of the authors not yet attempted. This paper presents a new etching technique for revealing the γ-dendrites in a hypoeutectic LGI of which solidification has been interrupted by quenching from the proeutectic semi-solid temperature range. A technique for measuring the volume fraction and surface area per unit is demonstrated and analyzed in comparison to point counting and line intercept techniques.

Methods and Material

Material

The characterization techniques presented in this paper are applied to a hypoeutectic LGI with approximate chemical composition as outlined in Table 1. From this base material, four versions (A, B, C, and D) were produced in portions of 400 g using remelting, isothermal heat treatment, and interrupted solidification as described by Hernando [19] resulting in cylindrical specimens of approximate dimensions Ø40 × 40 with dendritic microstructure of varying coarseness. The solidification of material A was interrupted soon after dendrite coherency at 1180 °C, marking the “0” reference point for the isothermal heat treatment. Material B, C, and D underwent a similar procedure, but instead of immediate quenching they were subjected to an isothermal heat treatment at 1168 °C for durations according to Table 2.

Sample Preparation and Etching

The specimens were cut in half perpendicular to the central axis using a wet abrasive cutter and were cold-mounted in Ø50 mm epoxy pieces. Porosities and cracks were filled with the resin as good as possible to facilitate subsequent preparation. After having cured for at least 12 h, the samples were ground individually by manual application to a water-lubricated SiC foil #80 on a rotating disk until planar and subsequently transferred to an advanced sample preparation system where it was ground on a #220 resin bonded diamond disk with water lubrication until deep scratches appeared gone followed by a composite disk with a 9 µm diamond suspension for 2 min and 30 s. The specimen was then polished on a taffeta woven wool cloth disk with a 3 µm diamond suspension for 3 min and finalized on a synthetic short napped cloth with the DiaPro Nap B 1 µm diamond suspension for 2 min and 20 s with 5 N force applied. If the material is similar and the sample preparation so far described is followed (with emphasis on the last polishing step), the surface should at this point already appear etched. If required, additional polishing time with the DiaPro Nap B 1 µm diamond suspension was added in increments of 20 s until the coloration appeared similar to Fig. 1 or the γ-dendrites were otherwise clearly distinguishable. If the martensite in the dendrites were significantly darkened such that it was judged to interfere with the subsequent measurements, it was in this investigation considered overetched and was reprepared for a new trial.

Microscopy and Selection of ROI

Using an optical microscope, the full Ø40 mm surface of the specimen was captured digitally in a systematic manner at 2.5× magnification using at least 1/3 overlap, making a total of about 200 micrographs per specimen that were stitched into a large single panorama image. On each panorama, four 5 mm × 5 mm sample regions were selected for analysis on the basis of avoiding defects and areas where dendrites were less clear.

Measured Microstructural Parameters

The microstructural object of interest in this article is the γ-dendrites, also often referred to as primary γ [10, 20–22] to emphasize that it is mostly known to form prior to the eutectic. This structure is however difficult to quantify directly while the material is still semi-solid and is instead studied at room temperature after rapid quenching. In the process of quenching, the liquid transforms into fine ledeburite termed “quench ledeburite,” while the γ-dendrites transform to martensite. It is in this study assumed that the shape of the martensitic dendrites closely resembles and is representative of the γ-dendrites microstructure before quenching and will from here on be referred to simply as “γ-dendrites.” Two parameters will be considered: the volume fraction V V and the specific surface area S V of the γ-dendrites. These parameters were selected for their importance in modeling of solidification phenomena [23–25] and are sufficient to derive other meaningful parameters such as the modulus of dendrites M D and the hydraulic diameter of interdendritic phases \( D_{\text{IP}}^{\text{Hyd}} \) [6].

Stereology

The microstructural parameters V V and S V are both volumetric properties; however, using stereological relationships, they can be derived from various types of measurements on a cross section of the specimen. Table 3 which has been adopted from Underwood [26] provides an overview of these relations. Studying the table it is realized that the two parameters are not stereologically connected and require separate measurements. V V (volume fraction) can be calculated from P P (point fraction), L L (line fraction) or A A (area fraction) and S V (surface area per unit volume) can be calculated from L A (line length per unit area) or P L (intercept points per line length). This article focuses on a computer-aided A A-based method for measurement of V V and a L A-based method for measurement of S V but a comparison to P P and P L will be made which is further described later in this article. V V, A A, and P P are equivalent \( V_{\text{V}} = A_{\text{A}} = P_{\text{P}} \). S V is however not equal but proportional to L A and P L and must be calculated using

as described in [26].

Adobe Photoshop Footnote 1 Quantification (PSQ)

The utilized image analysis software offers many useful tools for quantification of the microstructure. To identify phases, the software allows the user to interactively try to define a color filter such that pixels that are associated with the phase of interest are considered. The software then identifies isolated aggregates that can be considered as separate entities. A second filter can be applied to consider only aggregates that possess certain shape characteristics. It was however not possible to quantify the dendritic microstructure with satisfactory accuracy using these tools. Some researchers have turned to commercial [19, 27] as well as open source [28] raster graphics editors for alternative means of quantifying the microstructure. A popular approach is to draw the microstructural features by hand using, e.g., a mouse or a tablet [6, 19, 28], although some have experimented with a variety of selection tools [27]. In this study, it was attempted to use the Adobe Photoshop software’s more advanced selection tools to find a quicker technique to produce a representative selection. In line with Zhang et al. [27], this method will be referred to as Adobe Photoshop Quantification (PSQ). It has been noted that it is possible to find the number of selected pixels directly from the Adobe Photoshop software making it possible to calculate, e.g., the volume fraction [27], but to measure the perimeter of the selection, a complementary image analysis software is required. In order to combine the selection capabilities of the Adobe Photoshop CS6 software with the quantification capabilities of an image analysis software, the selected areas were filled with a single color that was in clear contrast with the background, producing a more easily interpreted analogue image of the microstructure which will be referred to as microstructure analogue. This process will now be explained in more detail. The selected portions of the panorama micrograph were exported to separate files and opened in the Adobe Photoshop CS6 software. The image was copied to a new layer on top of the original, and the color blending mode of the layer was changed to multiply. A vector mask was added to the layer. Using Color Range in the properties of the vector mask, the dendrites were masked on the basis of color. The fuzziness parameter of the color range was set to zero, meaning the selection will consist exclusively of exactly the colors that have been sampled. The colors included in the selection were defined by panning around the image at high magnification and sampling colors from the dendrites on the micrograph until all the colors that were associated with dendrites had been selected. A selection was then produced using the “Load Selection from Mask” function. Because the colors of the γ-dendrites were also found in other parts of the microstructure, the selection at this point typically looked like Fig. 2(a and b) which is not a satisfactory representation of the structure. The selection was modified using the “Contract Selection” tool which retracts the boundary of the selection by a specified number of pixels. For the finest dendritic structure (specimen A), this corresponded to 3 or 4 pixels. For specimen B, C, D, up to 6 pixels were contracted. After this step, the selection looked like in Fig. 2(c and d). Note how most of the undesired details in the space between the dendrites have been removed, but that the boundary of the dendrites is also contracted. The selection was then restored to the boundary of the dendrites using the “Expand Selection” tool by an equal number of pixels as it was contracted (Fig. 2e and f). Due to the nature of the contraction and expansion procedure, the resulting boundaries are crude. To make the boundary more representative of the dendrites, the “Smooth Selection” tool was applied for 2 pixels (Fig. 2g and h). A new layer was created on top of the others, and the selected area was colored using the fill function.

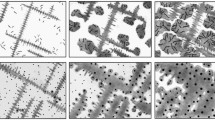

The selection at different stages of the selection process. Figure (a), (c), (e), and (g) are sampled from sample region A4 while (b), (d), (f), and (h) are taken from C3. Selected areas were colored black for clarity. The original micrograph can be seen in the background in (c)–(h), but in (a) and (b), the background was colored white to emphasize the level of detail. These images were reconstructed for the sake of demonstration and were not used for quantification

While the microstructure analogue now appears more representative of the dendritic structure, close inspection reveals discrepancies. To assess the error induced by these residual flaws, another microstructure analogue was produced where the flaws had been manually corrected using the lasso tool. Errors that were corrected included dendrites that had not been selected, selections that did not contain dendrites, separate dendrite arms that had been selected as one, intradendritic particles that were not selected, selection of eutectic cells, selection of the smaller set of dendrites that formed during quenching, and selection boundaries that were obviously offset from the actual dendrite boundaries. In cases where it was not clear whether the selected features were dendrites, no alterations were made. A new layer was created on top of the others, and the selection was colored in the same manner as before, but now with a different color. By changing the layer’s blending option to multiply, it was possible to produce an image where the two selections as well as their intersection could be displayed in one image as can be seen in Fig. 3. This enabled distinction between removed, added, and retained area which would help in later analysis. A plain white layer was created between the colored layers and the masked layer to serve as background. The multi-layer file was saved using the software’s standard PSD format for backup and the JPEG format with maximum quality as input for the image analysis software where the parameters were measured. The image analysis software was set up to measure the full areas and their perimeters. This means that objects on the boundary of the image were included and that no object shape filters were applied. It has been pointed out [27] that if only the area is of interest, the pixel count of a selected area can be counted directly in the Adobe Photoshop software using the histogram with expanded view. Note that to count the true number of selected pixels it may be necessary to make an “Uncached Refresh” using the button found in the top right of the histogram window. All measurements were made in the units of pixels. V V is unitless and in no need of conversion, however, S V is of reciprocal length and needs conversion to a more meaningful unit. An easy way to find the relation between pixels and metric units is to simply produce a micrograph with equivalent magnification that includes a metric ruler, then measure the number of pixels across the ruler. In this study, 1 mm corresponded to 460 pixels.

Corrections of the microstructure analogues. Black areas are unchanged. Red areas were removed. Blue areas were added. (a) and (b) correspond to the same areas as in Fig. 2

Line Intercept and Point Counting Methods

The PSQ measurements were compared to reference measurements acquired using line intercept and point counting methods. These measurements were performed on the raw micrographs of the same sample regions. Underwood’s [26] recommendation to use circular test lines for measurements of PL on highly oriented structures appears reasonable. Three concentric circles of Ø2 mm, Ø3 mm, and Ø4 mm were superposed over the center of each sample region. A cross was placed in the center to divide the circles into four equal quadrants. The number of dendrite boundary intersection points was counted separately in each quadrant. In cases where the line appeared to tangent a boundary but it was unclear whether it crossed or not, it was counted as 1 point (as opposed to both an entry and an exit point). P L was calculated as P L = P Ø /L Ø where P Ø is the number of intercept points and L Ø is the sum of circumferences of the circles superposed over the micrograph. S V was then calculated from P L according to (1) and will be referred to as S PLV . P P was measured using a 22 × 22 square grid (484 points) superposed over the sample regions. Each point was counted as on a dendrite, on its boundary or not on a dendrite. Boundary points were counted separately and weighted as ½ a point in the calculation to reduce subjectivity as recommended by [26]. P P was calculated as \( P_{\text{P}} = (P_{1} + \raise.5ex\hbox{$\scriptstyle 1$}\kern-.1em/ \kern-.15em\lower.25ex\hbox{$\scriptstyle 2$} P_{\raise.5ex\hbox{$\scriptstyle 1$}\kern-.1em/ \kern-.15em\lower.25ex\hbox{$\scriptstyle 2$} } )/P_{\text{T}}, \) where P 1 is the number of points that fell over a dendrite, P ½ is the number of boundary points, and P T is the total number of points in the grid.

Evaluation

The etching technique is evaluated qualitatively by looking at what microstructural components are colored and how representative the revealed patterns are of the γ-dendrite shape and area or how useful it is for quantification of the structure. The evaluation of the PSQ method will concern the accuracy of the produced microstructure analogues with respect to the two considered microstructural parameters V V and S V. The true values of the parameters are unknown, so to evaluate the method, its agreement to a reference method is instead analyzed. In this case, the reference methods for volume fraction and surface area measurements are the point counting and line intercept methods, respectively. The agreement analysis is inspired by Bland and Altman [29] who suggest plotting the differences between the measurements of two methods against their average values. If there is a significant mean difference between the methods, there is a systematic disagreement. The sample standard deviation of the differences on the other hand provides information about scatter or random disagreement. The differences are in this case obtained by \( d = x - x_{\text{ref}}, \) where \( x_{\text{ref}} \) is a reference measurement and \( x \) is the corresponding PSQ measurement. An advantage of this method is that it helps discern between what is actual variation in the properties of the different sample regions and materials and the variation induced by the measurement methods. The mean of the differences is calculated as

where the mean is denoted by bar accent, i is the index of the source micrograph the measurement was performed on, and n is the sample size. The sample standard deviation of the differences \( s \)(\( d \)) is calculated as

The significance of the mean difference is tested by calculating the sample standard deviation of the mean i.e., the standard error \( {\text{SE}}(d) = s\left( d \right)/\sqrt n \) and then calculating the 95% confidence interval for the mean \( {\text{CI}}_{95\% } \left( {\bar{d}} \right) = \bar{d} \mp 1.96*{\text{SE}}(d) \). If CI95% does not contain zero, the mean difference is considered significant meaning there is likely a systematic disagreement. It is also useful to consider the expected scatter of the reference methods. For the point counting method, the sample standard deviation is calculated as

where n is the total number of points, n 1, n ½, n 0,, and n T are the number of points on a dendrite, on its boundary, not on a dendrite, and the total number of points, respectively. Note that since P P is the mean of the 484 points, s(P P) is equivalent to the standard error of the mean of the points leading to Eq. (4). The sample standard deviation of S PLV is calculated from the subtotal S LAV of the four quadrants of the test circles

and the standard error simply \( SE\left( {S_{\text{V}}^{\text{PL}} } \right) = s\left( {S_{\text{V}}^{\text{PL}} } \right)/\sqrt 4 \). The measurements obtained from the manually corrected analogues are compared against PP and S PLV in an identical fashion, and the two analyses are compared side by side to determine the fruitfulness of the corrections. To discern between the two, measurements on the manually corrected analogues are denoted by an asterisk (*). The sample standard deviation of the measurements on the analogue was then estimated as

where x is the PSQ measurement and x ref is the reference measurement.

Results and Discussion

The Etching Technique

When specimens after the last polishing step were found etched, it was initially suspected that an impurity had unintentionally been introduced to the specimen during the process. However, after thorough cleaning of the polishing cloth and using a new bottle of the DiaProFootnote 2 Nap B 1 µm diamond suspension, the effect was still present. Since the effect had not been observed before (at least to this extent) either by the author or his colleagues, this was at first perplexing. It was later found that the effect could be reproduced by simply rubbing the same diamond suspension over the surface with a ball of cotton, but immersion of the specimen into the suspension was unsuccessful. Attempts to reproduce the effect on a furnace-cooled material of the same composition were unsuccessful, but after 9 min, colored spots appeared, typically in conjunction with carbides as can be seen in Fig. 4. Based on these observations, it is clear that the substance responsible for the coloring is contained in the DiaPro Nap B 1 µm diamond suspension. It is by the author suggested that the reason the effect has not been reported earlier is because the abrasion of the polishing process normally occurs at a higher rate than the etching, removing all traces of it. Assuming this is correct, the appearance of the coloring in this case can be attributed to an ineffective abrasion caused by a combination of the high hardness of the material, the large specimen area being polished (Ø40 mm in a Ø50 mm epoxy mount), and the low force applied to the specimen during polishing. In fact, the force applied during polishing on the Synthetic short napped cloth when the effect was first noticed was 20 N which corresponds to Struers recommendation for gray iron specimen in a Ø30 mm mount. For Ø30 mm white iron, Struers recommends 30 N and assuming the applied pressure should be independent of specimen size, the force should scale with the specimen area suggesting an appropriate force of 83.3 N. Examining the patterns revealed by the etchant at ×50 magnification, it became clear that the Fe3C in the ledeburite is unaffected by the etching and that the tint occurs only in the γ component (probably martensite after quenching) of the eutectic. The coloration was also found to vary significantly within the colored area and that the color spectrum appears similar to picric etching or what would be expected from a thin film of varying thickness (see Fig. 5). What chemical components of the diamond suspension are responsible for the effect as well as the mechanism by which the thin film is formed are not known. It is speculated that since the coloration occurs in the vicinity of Fe3C both in quenched specimens and furnace-cooled specimens, the thin film forms as a result of a reaction between a component of the diamond suspension and an alloying element that because of its micro segregation behavior is found in elevated concentrations around Fe3C. Another possibility is that the coloring appears in the vicinity of Fe3C simply because it is raised above the surrounding softer phases, producing pockets that are favorable sites for some component of the diamond suspension to become trapped or deposit. An effect of this etching procedure which in this case was undesirable is that martensite is often tinted, reducing the contrast between the dendritic structure and its surroundings (see Fig. 5). While this effect was definitely more common and prominent for longer etching times, its occurrence was rather sporadic and the tint was not strictly proportional to the tint of the quench ledeburite. The patterns that appear as a result of the etching clearly reveal the γ-dendrite microstructure; however, solidification phenomena associated with the interrupted solidification method can make interpretation difficult. First of all, a finer set of γ-dendrites was frequently found in connection with the coarser ones with the same preferred growth directions, especially near the edges of the specimen (Fig. 6). These have previously been identified as an artifact of quenching and are therefore termed quench-γ [2]. They can generally be identified as such based on their scale relative to the γ-dendrites that formed during furnace cooling. However, they could be deceiving by causing small protrusions on the γ-dendrites, distorting the shape of its original interface against the quench ledeburite (see Fig. 5). Tian and Stefanescu [17] also argues, using patterns revealed using color etching, that the dendrites grow epitaxially during quenching, which makes the dendrites appear thicker than they were prior to quenching. Small circular eutectic cells of γ and fine lamellar graphite were frequently found dispersed over the cross section of the specimen (Fig. 7). These were also considered to have formed during quenching due to their size. While this γ was often similarly colored as the γ-dendrites, the fine interspersed graphite generally made it possible to differentiate them from the γ-dendrites. Coarser bodies of Fe3C found in the quench ledeburite (see Fig. 6) could sometimes be confused with γ-dendrites, especially in material A, but were generally distinguished based on shape and the paler tint. The interface between the dendrites and the quench ledeburite appeared rugged at high magnification due to the coarseness of quench ledeburite which could influence the accuracy of the measurements (can be seen in Fig. 5). This was however most apparent in material A where the scale of the dendrites was smaller in relation to the ruggedness of the interface (Fig. 8). As mentioned, the γ-dendrites also transform into martensite which sometimes appears darker for the applied etching technique which may interfere with characterization.

The PSQ Technique for VV

Before the results are discussed, it seems necessary to clarify that while the volume fraction in Fig. 9 can be expressed in terms of percent, it is here expressed in decimal form to avoid confusion with the relative differences which have been normalized by the reference measurement and are in Figs. 10 and 11 denoted by percentages. The general impression of Fig. 9 is that the A A and A A* appears randomly scattered around P P. Calculation of the standard deviation of A A and A A* using Eq. (6) was not possible for material A and C because the standard deviation of the difference was smaller than the standard deviation of the reference method leading to a square root of a negative number. The reason is likely that only four measurements were compared on each material, causing a crude sample standard deviation of the differences which for this reason by chance ended up lower than the more accurate standard deviation of the reference method. However, for both material B and D as well as for all measurements together, the manual corrections reduced the standard of the measurement as can be viewed in Fig. 12. Considering all V V measurements, \( \bar{d}_{\text{PP}}^{\text{AA}} \) is according to Fig. 10 only −1.1% and insignificant. If the measurements on the different materials are instead considered separately, the measurements on material A do however display a systematic disagreement of between −7.5 and −15.5%, while the rest are not. Comparing Figs. 10 and 11, it appears that the manual corrections had surprisingly small impact on the agreement, only reducing the overall mean difference from −1.1 to −2.8% which is still insignificant. Manual corrections did in all cases involve both addition of new γ-dendrite areas that had been missed by the selection scheme as well as removal of areas that had been wrongfully characterized as γ-dendrites which for most measurements lead to a net reduction of A A* compared to A A. Comparing the analogues using the technique demonstrated in Fig. 3, it appears that the major part of the removed area consisted of area between adjacent dendrite arms (particularly for material A) and of similarly colored Fe3C or eutectic cells that had formed during quenching. The majority of the added area consisted of dendrites that had not, or had only partially, been selected, as a consequence of discolored martensite. Another common addition was dark particles found inside the dendrite arms but these generally constituted a small area in relation to the total. The fact that the corrections were small in relation to the differences (particularly in material A) indicates either that the reference values were considerably off or the majority of errors on the analogues were not easily discerned and therefore escaped manual corrections. Precautions were taken to ensure no points were missed by controlling that each row in the grid adds up to 22 points, and that the total adds up to 484 points, reducing the human error. Because of the effectiveness of the etching in revealing the microstructure, it is considered unlikely that a point over the bulk of a dendrite would be mischaracterized as something other than a dendrite, or that a point over a feature that is not a dendrite would be mischaracterized as a dendrite. It is therefore expected that mistakes primarily occur at the boundary. The point counting method deals with this by counting any point that appears to be on or very close to a boundary as half a point, reducing subjectivity. The systematic error of the point counting measurements is therefore considered low. However, even for as many as 484 points, a random error SE(P P) around 0.02 (5.1–8.0% after normalization) is inevitable due to the sheer statistical uncertainty bound to the sample size. Similarly, it is considered unlikely that discrepancies between the corrected analogue and the micrograph would occur in the bulk of the dendrites or interdendritic area. It is therefore entertained that the systematic disagreements of A A* of material A are related to discrepancies in the boundary of the dendrites in the analogues. Indeed, apart from the ruggedness of the boundary, a close examination of the raw micrographs reveals that the dendrite boundaries also appear as diffuse fields of about 3–4 pixels thickness. Contrary to the point counting method, it is up to the operator to define the boundary by the colors he chooses to sample and at what point he judges the boundary to be sufficiently representative. Moreover, the apparent location of the boundary may depend on factors like the lighting, the etching, or the fineness of the γ-dendrites. The problem is perhaps clarified by Fig. 13 where the analogue boundary is colored red against the original micrograph in the background. Note that an offset of the boundary by just one pixel causes an error in the measured area that is approximately equal to the length of the boundary measured in pixels, so a small error in the definition of the boundary can cause large errors for fine microstructures. The perimeter of the corrected analogues ranges from 316,772 pixels in A4 down to 89,445 pixels in material D3 which corresponds to 17.8 and 6.8% of the corrected area, respectively, which demonstrates the potential magnitude of this type of error. This could also explain why A A and A A* deviate significantly from P P in material A but not in B, C, and D.

The relative differences between the PSQ measurements and the reference point counting method before manual corrections had been employed. The dashed lines are the 95% confidence interval of PP as calculated using Eq. (4). Whiskers represent the 95% confidence intervals of the measurements

The relative differences between the PSQ measurements and the point counting method after manual corrections had been employed. The dashed lines are the 95% confidence interval of PP as calculated using Eq. (4). Whiskers represent the 95% confidence intervals of the measurements

The relative standard deviation of A A and A A* as calculated using Eq. (6). Material A and B are excluded because it was not possible to make the calculations

The PSQ Technique for SV

The calculations of the standard deviation of S LAV and S LA*V suffered the same problems as for the volume fraction, probably for the same reasons, meaning it was not possible to make the calculation for A, B, and C. It was however possible to make the calculation for material D and for all materials as displayed in Fig. 17 which both indicated a drop in standard deviation. It must however be emphasized that the estimation of the standard deviation of the line intercept method was crude so this can be a coincidence. Interestingly, studying Fig. 14, the measurements of S V display a different pattern compared to V V in Fig. 9. This is even more clear in Fig. 15, where \( \bar{d}_{\text{PL}}^{\text{LA}} \) is significantly positive in material B, C, and D, while slightly negative in material A. All measurements considered, S LAV was overestimated by between 4.8 and 13.2% relative to S PLV . By comparing Figs. 15 and 16, we can see that after the manual corrections, \( \bar{d}_{\text{PL}}^{\text{LA*}} \) was reduced by about 1% overall. In fact, \( \bar{d}_{\text{PL}}^{\text{LA*}} \) was on average reduced in material B, C, and D but only in D was the reduction sufficient to bring \( \bar{d}_{\text{PL}}^{\text{LA*}} \) down to insignificance. In material A, the manual corrections instead produced an increase of \( \bar{d}_{\text{PL}}^{\text{LA*}} \) though still insignificant. The estimations of s(S PLV ) based on quadrants proved to be crude and showed large variation. A line-fit of the confidence interval is added to Figs. 15 and 16 but these should only be viewed as a rough approximation. The influence of the various corrections on the measured A A is intuitive since added area increases A A and removed area increases it. The influence of corrections on S LA*V is however more complex since perimeter can either be added or removed by either adding or removing area (Fig. 17). Corrections made on material A were dominated by the addition of dendrite arms that had not been selected and removal of area between adjacent dendrite arms. While the prior adds and the latter removes area, both corrections increase S AA*V by adding perimeter which explains the net positive contribution to S AA*V of manual corrections in A. In the coarser specimens, B, C, and D corrections were dominated by removal of similarly colored eutectic cells and large Fe3C details which reduced S AA*V . Moreover, dendrites were typically not wholly missed in B, C, and D but partially selected which after correction often also lead to a lower S AA*V by removal of internal details of the arms and by drawing a new smoother dendrite boundary. It is considered unlikely that errors are committed and go unnoticed in the bulk of the dendrites or interdendritic. It is therefore suggested that the residual positive systematic disagreement of S AA*V is most likely caused by irregularities of the boundaries in the analogues, which remain after the “Smooth Selection” tool has been applied. The reason this error is not as prominent in specimen A is likely because a smoothing radius of 2 pixels is in that case enough to produce a more representative boundary while for the coarser structures which feature smoother γ-dendrite boundaries it is insufficient, leaving a relatively irregular boundary. Compare the smoothness of the dendrite boundaries to the boundaries of the analogue in Fig. 13.

The relative standard deviation of S LA V and S LA* V as calculated using (6). Material A, B, and C are excluded because it was not possible to make the calculations

Wrapping Up

The volume fraction measurements using the PSQ method tended to underestimate A A for the finest γ-dendrites in relation to P P but no significant disagreement was found for the coarser γ-dendrites. The manual corrections provided no clear improvement with regard to systematic disagreement. The surface area measurements S LAV on the other hand were overestimated relative to S PLV for the coarser γ-dendrites but slightly underestimated for the finest, and manual corrections tended to reduce disagreement. After a close inspection, the disagreements seem to be consistent with observed discrepancies between the boundaries of the microstructure analogues and the raw micrographs, and most of the errors appear to have remained after correcting the more obvious flaws, so it seems reasonable to at least partially attribute the biases to the poorly represented dendrite boundary of the microstructure analogues. One approach to improving the method would be to further manipulate the selection with the Adobe Photoshop software’s tools at hand until a more representative boundary is achieved, such as increasing the smoothing radius for the coarser γ-dendrites to iron out irregularities, or expanding or contracting the selection to reduce offset, or increasing the level of detail considered for manual corrections. This would however introduce more variables and subjectivity and demand more skill of the operator, and it must be kept in mind that at some point the work-load of these corrections may become greater than point counting and line intercept methods [26] or wholly manually drawn microstructure analogues [19] for the same level of accuracy which would defeat its purpose. A wiser approach is perhaps to focus on eliminating the reasons why these secondary steps are needed in the first place. If there was no need for the contract-expand-smooth selection scheme, it would perhaps be possible to reduce the difficulty and labor while at the same time increasing accuracy. Much is still unknown about the mechanism of the presented etching technique and there is certainly room for improvements. By isolating the active components of the diamond suspension which cause the desired coloring, it may be possible to prevent undesired effects such as the discoloration of the martensite and increase the contrast between the quench ledeburite and dendrites and thereby reduce the need for corrections. Also, as mentioned in the introduction, other promising etching methods exist that have so far not been used for quantification of the γ-dendrite microstructure, such as Beraha’s Selenic Acid reagent [18]. Perhaps these can even be combined with the presented etching technique to color both components of the ledeburite. The problem of distinguishing dendrite arms from quench eutectic cells is due to their similar chemical and phase composition likely difficult to solve through etching. The quench eutectic cells can however be regarded as artifacts of ineffective quenching, so it may be better to focus on improving the quenching conditions. This could potentially also reduce the ruggedness of the interface between the quench ledeburite and the γ-dendrites by reducing its scale. The problem of defining a definite boundary on a not-so sharp micrograph can however be difficult to overcome. One could assume that simply increasing the magnification would solve the problem, but this is done at the cost of the total measured area, demanding more micrographs for the same representativeness. Also, even if an equal area is covered, increasing the magnification will likely reveal more Fe3C details in the ledeburite which become accidentally selected due to its similar color. Increasing the magnification would therefore only be fruitful combined with an improved means of distinguishing the Fe3C from the γ-dendrites.

Conclusions

A hypoeutectic lamellar graphite iron has been quenched after various durations of isothermal heat treatment in the semi-solid proeutectic temperature range. A new color etching technique has been presented and demonstrated useful for quantification of γ-dendrite microstructure. A procedure for measuring V V and S V of the γ-dendrites on these micrographs was presented, involving the construction of analogues of the micrographs using the Adobe Photoshop CS6 software followed by a combination of an image analysis software and stereological relations. The agreement between said measurements and measurements obtained using point counting and line intercept methods was analyzed. From the results, the following was concluded:

-

The presented etching technique was found useful for quantification of the γ-dendrites due to the relatively uniform coloring and good contrast between the dendrites and the quench ledeburite. The martensite was however sporadically tinted which made it more difficult to define the γ-dendrites on the basis of color.

-

The agreement between the measurements depended on the coarseness of the measured dendritic microstructure. Disagreement was the largest for A A relative to P P for material A A with 7.5–15.5% significant disagreement but was insignificant for material B, C, and D. Agreement between S LAV and S PLV on the other hand was best for material A and disagreed significantly for material B, C, and D.

-

Manual corrections had small influence on the systematic agreement between the methods for both S V and V V meaning that most systematic error cannot be attributed to obvious discrepancies between the microstructure analogue and the micrograph. Using qualitative evidence, it is deduced that residual bias is likely related to the difficulties and subjectivity of defining the location and shape of the boundary of the dendrites.

-

Calculation of the standard deviation for the measurements of A A, A A*, S LAV , and S LA*V failed in some cases due to the poor approximation of the standard deviation of the differences \( s(d_{\text{PP}}^{\text{AA}} ), s(d_{\text{PP}}^{\text{AA*}} ), s(d_{\text{PL}}^{\text{LA}} ) \) and \( s\left( {d_{\text{PL}}^{\text{LA*}} } \right) \). However, in the cases it was possible to calculate the standard deviation, it was every time smaller after manual corrections. This indicates that some random error can be attributed to discrepancies between the microstructure analogue and the micrograph that are easily identified by an operator. Moreover, the majority of these discrepancies can be attributed to either an inadequately rapid quenching process resulting in quench eutectic cells and coarse quench ledeburite or to undesired tinting of the martensite in the dendrites.

Future Work

The results of this paper indicate that improvements in characterization of γ-dendrites can be made by improving the experimental and sample preparation techniques. It is therefore suggested that future work includes

-

An evaluation of suitability of other available etching techniques for the purpose of quantification of γ-dendrites in interrupted gray irons is warranted.

-

A deeper investigation on the mechanism behind the etching technique presented in this paper and how it can be improved to more clearly reveal the dendrites.

Notes

Adobe Systems Incorporated, 345 Park Avanue, San Jose, CA 95110-2704, USA.

Struers A/S, Pederstrupvej 84, 2750 Ballerup, Denmark.

References

R.W. Heine, C.R. Loper, On dendrites and eutectic cells in gray iron. AFS Trans. 77, 185–191 (1969)

K.R. Olen, R.W. Heine, A revision of the Fe-C-Si system. Cast Met. Res. J. 4(1), 28–43 (1968)

G.L. Rivera et al., Examination of the solidification macrostructure of spheroidal and flake graphite cast irons using DAAS and EBSD. Mater. Charact. 59, 1342–1348 (2008)

A. Diószegi, L. Elmquist, S. Adolfsson, Characterizing shrinkage porosity in gray cast iron using microstructure investigation. AFS Trans. 105, 691–703 (2008)

L. Elmquist, A. Diószegi, On the problems of a migrating hot spot. Mater. Sci. Forum 649, 443–448 (2010)

R. Lora, A. Diószegi, Dynamic coarsening of 3.3C–1.9Si gray cast iron. Metall. Mater. Trans. A 43(13), 5165–5172 (2012)

V. Fourlakidis, A. Diószegi, A generic model to predict the ultimate tensile strength in pearlitic lamellar graphite iron. Mater. Sci. Eng. A 618, 161–167 (2014)

P.K. Basutkar, S.A. Yew, C.R. Loper, Effect of certain additions to the melt on the as-cast dendritic microstructure of gray cast iron. AFS Trans. 77, 321–328 (1969)

J.M. Motz, Microsegregation an easily unnoticed influencing variable in the structural description of cast materials. Pract. Metallogr. 25, 285–293 (1988)

S.M.A. Boutorabi, J. Campbell, An etching technique for primary austenite dendrites in ductile cast iron. Mater. Charact. 31, 127–132 (1993)

G.L. Rivera, R.E. Boeri, J.A. Sikora, Revealing the solidification structure of cast iron. Cast Met. 8(1), 1–5 (1995)

S. Vazehrad, Study of microstructure and silicon segregation in cast iron using color etching and electron microprobe analysis. Mater. Charact. 104, 132–138 (2015)

R. Lora, A. Diószegi, L. Elmquist, Solidification study of gray cast iron in a resistance furnace. Key Eng. Mater. 457, 108–113 (2010)

S. Vazehrad, J. Elfsberg, A. Diószegi, On factors influencing macro shrinkage porosity formation in compacted graphite iron. Mater. Sci. Forum. 740, 429–434 (2014)

A. Diószegi, V. Fourlakidis, R. Lora, Austenite dendrite morphology in lamellar graphite iron. Int. J. Cast Met. Res. (2015). doi:10.1179/1743133615Y.0000000018

A. Hultgren, Y. Lindblom, E. Rudberg, Eutectic solidification in grey, white, and mottled hypo-eutectic cast irons. J. Iron Steel Inst. 176, 365–374 (1954)

H. Tian, D.M. Stefanescu, Application of a coloration etching method to the study of microstructures in primary and eutectic. Mater. Charact. 29(3), 329–333 (1992)

E. Beraha, B. Shpigler, Color Metallography (American Society for Metals, Metals Park, OH, 1977)

J.C. Hernando, A. Diószegi, An overview of isothermal coarsening in hypoeutectic lamellar cast iron, in Advances in the Science and Engineering of Casting Solidification, ed. by L. Nastac, B. Liu, et al. (Wiley, New York, 2015), pp. 295–302

C.R. Loper, R.W. Heine, Graphite formation during solidification of cast iron. AFS Trans. 69, 583–600 (1962)

A. Diószegi, K.Z. Liu, I.L. Svensson, Inoculation of primary austenite in grey cast iron. Int. J. Cast Met. Res. 20(2), 68–72 (2007)

L. Elmquist, P.A. Sonawane, On the relation between primary and eutectic solidification structures in gray iron. IOP Conf. Ser. 27, 012060 (2012)

G. Lesoult, M. Castro, J. Lacaze, Solidification of spheroidal graphite cast irons—I. Phys. Model. Acta Mater. 46(3), 983–995 (1998)

Mampaey, F. and Z.A. Xu, A model for austenite dendrite growth in cast iron, in 62nd World Foundry Congress, Philadelphia, Pennsylvania, 1996, p. 1–11

S.P. Marsh, M.E. Glicksman, Overview of geometric effects on coarsening of mushy zones. Metall. Mater. Trans. A 27A, 557–567 (1996)

E.E. Underwood, Quantitative Stereology. Metallurgy and Materials (Addison-Wesley Publishing Company, Reading, MA, 1970), p. 274

X. Zhang et al., Adobe photoshop quantification (PSQ) rather than point-counting: a rapid and precise method for quantifying rock textural data and porosities. Comput. Geosci. 69, 62–71 (2014)

A. Diószegi, R. Lora, V. Fourlakidis, Dynamic coarsening of austenite dendrite in lamellar cast iron part 1—investigation based on interrupted solidification. Mater. Sci. Forum 790–791, 205–210 (2014)

J.M. Bland, D.G. Altman, Statistical methods for assessing agreement between two methods of clinical measurement. Int. J. Nurs. Stud. 47(8), 931–936 (2010)

Acknowledgments

The present work is part of a research project “SPOFIC II” within the Swedish Casting Innovation Center (CIC), financed by VINNOVA_Swedish Governmental Agency for Innovation Systems (2013-04720). The project is a collaboration between Scania CV AB, Volvo Powertrain Production Gjuteriet AB, Swerea SWECAST and Jönköping University. All participating personnel from these institutions/companies are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s13632-017-0362-9.

Rights and permissions

About this article

Cite this article

Domeij, B., Hernando, J.C. & Diószegi, A. Quantification of Dendritic Austenite After Interrupted Solidification in a Hypoeutectic Lamellar Graphite Iron. Metallogr. Microstruct. Anal. 5, 28–42 (2016). https://doi.org/10.1007/s13632-015-0250-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0250-0