Abstract

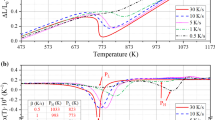

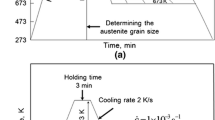

The application of large-size plastic injection molds is continuously increasing in automotive and aerospace industries. Having uniform hardenability over the entire volume of the large forged steel blocks is an important scientific and technological challenge. In the present paper, the influences of chemical composition and cooling rate on the kinetics of phase transformations in three medium carbon low alloy forged steels were investigated. A combination of high-resolution dilatometry, light and electron microscopy, X-ray diffraction analysis, electron backscattered diffraction mapping, and microhardness measurements were employed to accurately determine the critical transformation temperature, identify microstructural constituents (martensite, bainite, pearlite, ferrite, and retained austenite), and quantify the percentages of retained austenite for each experimental condition. Using seven different cooling rates (from 0.003 to 3 °C s−1), the continuous cooling transformation diagrams were constructed for the three investigated steels. The influences of composition and cooling rate on transformation kinetics were analyzed and quantified using the carbon equivalent (CE) notion. The obtained results showed the early formation of bainite at a cooling rate of 0.01 °C s−1 for the steel with higher value of CE. Similarly, it was found that the incubation time for ferrite and pearlite formation is influenced by the CE value, while for some cooling rates martensitic transformation occurred regardless of CE values.

Similar content being viewed by others

References

F. Beaudet, C. Blais, H. Lehuy, B. Voyzelle, G. L’esperance, J.P. Masse, M. Krishnadev, Improvement of hardenability and static mechanical properties of P20 + 0.5Ni mold steel through additions of vanadium and boron. ISIJ Int. 52(3), 424–433 (2012)

C. Maidorn, D. Blind, Solidification and segregation in heavy forging ingots. Nucl. Eng. Design 84, 285–296 (1985)

B.C. Kandpal, A. Chutani, A. Gulia, Harsimran, C. Sadanna, A review on jominy test and determination of effect of alloying elements on hardenability of steel using jominy end quench test. Int. J. Adv. Eng. Technol. 1(3), 65–71 (2011)

A.K. Sinha, in Defects and Distortion in Heat-Treated Parts, ed. by ASM International Handbook committee. ASM Handbook, vol 4 (ASM International, USA, 1991), pp. 601–619

H.D. Merchant, G.S. Murty, S.N. Bahadur, L.T. Dwivedy, Y. Mehrotra, Hardness-temperature relationships in metals. J. Mater. Sci. 8, 437–442 (1973)

D. Aliya, S. Lampman, in Physical Metallurgy Concepts in Interpretation of Microstructures, ed. by G.F. Vander Voort. ASM Handbook, vol 9 (ASM International, USA, 2004), pp. 44–70

Institut de recherches de la sidérurgie française (IRSID): Atlas des courbes de transformation des aciers de fabrication française (1974)

H.S. Fang, Novel hot rolling bainitic steel low carbon Mn-B series engineering steels 12Mn-B and 16Mn-B. Met. Mater. Res. 4(12), 913–923 (1976)

F.Y. Xu, Y.W. Wang, B.Z. Bai, H.S. Fang, CCT curves of low-carbon Mn-Si steels and development of water-cooled bainitic steels. J. Iron Steel Res. Int. 17(3), 46–50 (2010)

M.C. Zhao, K. Yang, F.R. Xiao, Y.Y. Shan, Continuous cooling transformation of undeformed and deformed low carbon pipeline steels. Mater. Sci. Eng. A 335, 126–136 (2003)

W. You, W.H. Xu, Y.X. Liu, B.Z. Bai, H.S. Fang, Effect of chromium on CCT diagrams of novel air-cooled bainite steels analyzed by neutral network. J. Iron Steel Res. Int. 14(4), 39–42 (2007)

D.B. Park, J.W. Lee, Y.S. Lee, K.T. Park, W.J. Nam, The effects of alloying elements on tensile strength and the occurrence of delamination in cold-drawn hyper-eutectoid steel wires. Met. Mater. Int. 15, 197–202 (2009)

K.A. Taylor, S.S. Hansen, Effects of vanadium and processing parameters on the structures and properties of a direct-quenched low-carbon Mo-B steel. Metall. Trans. A 22A, 2359–2374 (1991)

A. Todić, D. Čikara, T. Todić, I. Čamagić, Influence of vanadium on mechanical characteristics of air-hardening steels. FME Trans. 39, 49–54 (2011)

Y.H. Huang, C.J. Liu, M.F. Jiang, Effects and mechanisms of vanadium on structural transformation of BVRE heavy rail steel. Adv. Mater. Res. 146–147, 1216–1221 (2010)

T. Suzuki, Y. Ono, G. Miyamoto, T. Furuhara, Effects of Si and Cr on bainite microstructure of medium carbon steels. ISIJ Int. 50(10), 1476–1482 (2010)

M.M.A. Bepari, K.M. Shorowordi, Effects of molybdenum and nickel additions on the structure and properties of carburized and hardened low carbon steels. J. Mater. Process. Technol. 155–156, 1972–1979 (2004)

Ş. Talaş, The assessment of carbon equivalent formulas in predicting the properties of steel weld metals. Mater. Design 31, 2649–2653 (2010)

S.K. Dhua, D. Mukerjee, D.S. Sarma, Weldability and microstructural aspects of shielded metal arc welded HSLA-100 steel plates. ISIJ Int. 42(3), 290–298 (2002)

J.H. Kim, Y.J. Oh, I.S. Hwang, D.J. Kim, J.T. Kim, Fracture behavior of heat-affected zone in low alloy steels. J. Nucl. Mater. 299(2), 132–139 (2001)

T. Mohandas, G.M. Reddy, B.S. Kumar, Heat affected zone softening in high strength low alloy steels. J. Mater. Process. Technol. 88(1–3), 284–294 (1999)

N. Yurioka, T. Kasuya, A chart method to determine necessary preheats in steel welding. Weld. World 35(5), 327–334 + 367–388 (1995)

T. Kasuya, K. Ichikawa, M. Fuji, Derivation of carbon equivalent to assess hardenability of steel. Sci. Technol. Weld. Join. 3(6), 317–320 (1998)

Y.V. Konovalov, Y.V. Furman, A.E. Rudnev, V.G. Nosov, V.N. Fishev, V.M. Shcherbak, N.N. Shkurko, I.E. Pilipenko, N.N. Popov, Optimizing the chemical composition of rolled plate. Metallurgist 30(10), 364–365 (1986)

P. Parhad, S. Umale, A. Likhite, J. Bhatt, Characterization of inoculated low carbon equivalent iron at lower austempering temperature. Trans. Indian Inst. Met. 65(5), 449–458 (2012)

H.K. Sung, S.Y. Shin, B. Hwang, C.G. Lee, N.J. Kim, S. Lee, Effects of carbon equivalent and cooling rate on tensile and Charpy impact properties of high-strength bainitic steels. Mater. Sci. Eng. A 530, 530–538 (2011)

L.J. Habrakan, M. Economopoulos, Bainitic microstructures in low-carbon alloy steels and their mechanical properties. Transform. Hardenabil. Steels 32, 69–107 (1967)

Z.X. Qiao, Y.C. Liu, L.M. Yu, Z.M. Gao, Formation mechanism of granular bainite in a 30CrNi3MoV steel. J. Alloy. Compd. 475, 560–564 (2009)

ASTM Standard E 975-03, Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation. Annual Book of ASTM Standards ((Reapproved) 2008)

S.M.C. Van Bohemen, J. Sietsma, The kinetics of bainite and martensite formation in steels during cooling. Mater. Sci. Eng. A 527, 6672–6676 (2010)

N. Luzginova, L. Zhaoa, J. Sietsma, Evolution and thermal stability of retained austenite in SAE 52100 bainitic steel. Mater. Sci. Eng. A 448, 104–110 (2007)

Z.X. Qiao, Y.C. Liu, L.M. Yu, Z.M. Gao, Incompleted bainitic transformation characteristics in an isochronally annealed 30CrNi3MoV steel. J. Alloy. Compd. 478, 334–440 (2009)

K. Ogawa, T. Sawaguchi, S. Kajiwara, Isothermal fcc/hcp transformation in Fe-Si-C-alloy thermally treated at lower bainitic transformation temperature. Mater. Trans. 50(12), 2778–2784 (2009)

F.G. Caballero, M.K. Miller, C. Garcia-Mateo, J. Cornide, New experimental evidence of the diffusionless transformation nature of bainite. J. Alloy. Compd. (2012). doi:10.1016/j.jallcom.2012.02.130

R.A. Rijkenberg, M.P. Aarnts, F.A. Twisk, M.J. Zuijderwijk, M. Knieps, H. Pfaff, Linking crystallographic, chemical and nano-mechanical properties of phase constituents in DP and TRIP steels. Mater. Sci. Forum 638–642, 3465–3472 (2010)

S. Zaefferer, P. Romano, F. Friedel, EBSD as a tool to identify and quantify bainite and ferrite in low-alloyed Al-TRIP steels. J. Microsc. 230(8), 499–508 (2008)

R. Petrov, L. Kestens, A. Wasilkowska, Y. Houbaert, Microstructure and texture of a lightly deformed TRIP-assisted steel characterized by means of the EBSD technique. Mater. Sci. Eng. A 447, 285–297 (2007)

L. Ryde, Application of EBSD to analysis of microstructures in commercial steels. Mater. Sci. Technol. 22, 1297–1306 (2006)

J. Elmer, T. Palmer, S. Babu, W. Zhang, T. Debroy, Direct observations of austenite, bainite and martensite formation during arc welding of 1045 steel using time resolved X-ray diffraction. Weld. J. 83(9), 244–255 (2004)

Acknowledgments

The authors are very grateful to Mr. Raymond Beauvais, Director Metallurgy at Sorel Forge, Québec, Canada for his technical support in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chentouf, S.M., Jahazi, M., Lapierre-Boire, LP. et al. Characteristics of Austenite Transformation During Post Forge Cooling of Large-Size High Strength Steel Ingots. Metallogr. Microstruct. Anal. 3, 281–297 (2014). https://doi.org/10.1007/s13632-014-0142-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-014-0142-8