Abstract

The reflectivity of homogeneous binary gold alloys of formula AuxM1-x, where M is silver, platinum, and palladium, has been modelled using only the available optical constants of the pure parent metals, gold, silver, platinum, and palladium. The estimated reflectivity curves are compared with experimentally determined reflectivity curves for some of these alloys. It is seen that the great flattening of reflectivity curve in the visible spectrum is instigated by the addition of platinum and palladium. These metals have an almost identical decolorizing effect in gold alloys. The silver addition to gold is much more benign in this respect. The results were shown to give reasonable approximations, suggesting that the method has utility for the estimation of the reflectivity of alloys when no experimental data are available.

Similar content being viewed by others

Introduction

Gold is widely used in applications that require a large degree of chemical inertness, such as in electronic circuits, coins, dentistry, and jewelry. The disadvantageous mechanical properties of gold, especially softness and ductility, have to be offset, and to this end, the pure gold is alloyed with other metals. Unfortunately, an accompanying effect of alloying is to cause the yellow color of gold to be lost, thus “decolorizing” the gold.

As an example, palladium and platinum are usually added to dental noble metal alloys for porcelain-fused-to-metal (PFM) restorations. Among noble metal alloys for porcelain bonding there are three types of gold-based alloys: Au-Pt-Pd, Au-Pd-Ag, and Au-Pd alloys [1]. The Au-Pt-Pd alloys have an Au content ranging up to 88 mass% with varying amounts of Pd, Pt, and small amounts of base metals, such as Fe, In, and Sn, for porcelain bonding [1, 2]. The Au-Pd-Ag alloys contain between 39 and 77 mass% Au, up to 35 mass% Pd, and Ag levels as high as 22 mass% [1]. The Au-Pd alloys have an Au content ranging from 44 to 55 mass% and a Pd level of 35 to 45 mass% [1]. In addition to these traditional Pd-containing Au-based PFM alloys, Pd-free Au-Pt-based alloys for porcelain bonding were developed more than a decade ago and introduced into the dental alloy market.

The primary purposes of the addition of Pd and/or Pt to Au-based PFM alloys are to raise melting temperatures, increase sag resistance at a porcelain firing temperature, and harden the alloys resulting from solid solution hardening, the formation of precipitates, or from the pre-precipitation or zone formation reaction [2–4]. However, it is well known that the addition of Pd and/or Pt accompanies causes decolorizing of gold and as a consequence Au-Pd-Ag and Au-Pd alloys containing considerable amounts of Pd are white-colored [3].

The color of gold is due to the steep change in reflectivity across an absorption edge from low to high that occurs at between approximately 500–600 nm [5–8]. The decolorizing effect of the addition of other metals, especially Pd and/or Pt, is a result of the flattening of spectral reflectance curves over the visible spectrum, thus decreasing the change in reflectivity across the visible [9]. This is especially so in the case of the various white gold alloys [10, 11]. However, the degree of significance of the decolorizing effect of both elements (Pd, Pt) has not been numerically compared.

The primary aim of the present communication attempts to quantify the decolorizing effect of Pd and Pt when these elements are added to Au to form binary alloys. At a fundamental level, it is possible to use density functional theoretical approaches to calculate the electronic ground state of the alloys and then extrapolate these findings to compute the dielectric and optical properties of the materials [12]. However, in this paper, we show that the decolorizing effect can be evaluated by estimating the reflectivity of the alloys using the available optical constants of the parent metals in the alloy. The system Au-Ag was included for comparison as experimental data are readily available and so can be used to assess the reliability of the method. The results of these estimates, taken together, provide a useful guide to alloy reflectivity, not only to dental alloy manufacturers but also to the jewelry and other industries, when measured optical properties of alloys are not available.

Method

The optical properties of pure metals are determined by the complex refractive index, N:

where n is the refractive index, k the absorption coefficient, i is the complex operator, (√-1), and n and k are together called the optical constants of the metal. Both n and k vary with the wavelength of the incident electromagnetic radiation. The reflectivity of a pure metal surface depends upon the optical constants appropriate to the wavelength of light and its polarization. For light falling perpendicularly onto a smooth surface, the polarization can be ignored and the reflectivity is then given by:

The color of an alloy will depend critically upon the microstructure of the material. An alloy composed of particles of several phases will possess color properties derived from those of the individual phases, and the color perceived would be anticipated to be dependent upon the grain size, orientation, and relative proportions of the phases present. On the other hand, a homogeneous material would be expected to show color properties dependent only upon the relative proportions of the component atoms present. In this initial study, alloys AuxM1-x, comprising AuxAg1-x, AuxPt1-x, and AuxPd1-x, have been selected. This is because the crystal structure of the alloy (prepared at high temperatures and cooled rapidly) is homogeneous and identical to that of both parents, being the A1 (face-centered cubic) type. In all alloys, the parent atoms, Au, and M are distributed at random over the sites of the face-centered cubic structure [13, 14].

In order to estimate the reflectivity of these homogeneous alloys with respect to composition, it has been assumed that the optical constants of the alloy (and hence the reflectivity) can be obtained by combining the optical constants of the pure metals in proportion to the composition of the alloy. The use of the composition in this way is similar to that used in both organic and inorganic chemistry for the determination of refractive indices of mixtures or complex phases. For example, the refractive index of mixed organic liquids or inorganic glassy solids can be estimated by assuming that the refractive index of the mixture is a linear function of the volume concentration of the components [15]. Similarly, the molar refractivity of an organic molecule can be estimated by the addition of the atomic refractivity of the constituents of the molecule [16], and the refractive index of complex inorganic solids can be estimated by using the Gladstone-Dale equation, which adds together the “refractive coefficients” of the components that make up the compound [17].

As a first-order approximation of the reflectivity of a binary alloy homogeneous solid solution of composition AxB1-x, over the composition range from pure A (x = 1) to pure B (x = 0), it has been assumed that the optical constants of the parent metals A and B contribute to the optical constants of the alloy in proportion to the atomic composition, so that:

This linear dependence on the atom fractions can be thought of as ideal behavior. The ideal reflectivity of the alloy can then be assessed by using:

In these equations, x can be taken as the atom fraction of metal A, which is the same as the composition as written above, and can also be expressed as:

The reflectivity of ternary and quaternary alloys, such as those used to produce white gold alloys [10, 11], can be estimated in a similar way. For a ternary system, AxByCz use:

where the atom fractions are now x, y, and z, and

The real behavior of the alloys, see, i.e., [6, 7, 18], shows that the reflectivity of a homogeneous alloy can fall outside of the range given by Eq. 1. Such deviations can be treated in a second-order approximation by adding a bowing constant to the equations:

where b n is the bowing constant appropriate to the refractive index. Similarly:

where b k is the bowing constant appropriate to the absorption coefficient. The reflectivity of the alloy is now given by:

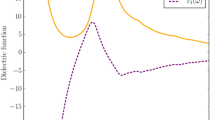

Because the optical constants of the pure metals are strongly wavelength-dependent, it is likely that any bowing constants will also be wavelength-dependent and may also be composition-dependent. It is found that positive values of b n and negative values of b k both bow the ideal curve towards higher reflectivity, while negative values of b n and positive values of b k bow it in the opposite direction, towards lower values of reflectivity (Fig. 1).

For any set of n A , k A , n B , and k B values, appropriate to a particular wavelength, a range of b n and b k values may give rise to a single R alloy value for a composition x. It is thus not possible to derive unique bowing constants as a function of alloy composition x and wavelength λ from reflectivity data alone. However, there are a number of ways in which bowing constants can be empirically assessed when experimental reflectivity data are available.

The form of Eq. 2 can be plotted (preferably in an interactive form), and values of b n and b k varied until a fit between the computed and experimental values of R alloy is achieved. Alternatively, where the reflectivity of the alloy is equal to the reflectivity of either of the pure parent metals, an estimate of empirical bowing constants can be made by setting the unknown optical constants of the alloy as equal to the optical constants of the pure parent phase. For example, if the reflectivity curve for the alloy crosses that of parent A at a wavelength λ:

hence:

and similarly for b k :

If the reflectivity curve for the alloy crosses that of parent B at wavelength λ:

hence:

and similarly for b k :

These empirical bowing constants will, strictly speaking, be relevant for only the alloy composition and wavelength used, but they give an indication of the order of magnitude of these quantities and can be used as a starting point for the refinement of calculated reflectivity curves via Eq. 2 if that degree of detail is desirable.

The values of the optical constants used in this study, listed in Table 1, are those given in references [19, 20], taken to three decimal places.

Results and discussion

Au-Ag

The reflectivity of homogeneous alloys AuxAg1-x, with x taking values of 0 to 1 in steps of 0.1, were determined using Eq. 1 and the optical constants of gold and silver given in Table 1, between the wavelengths of 350 and 750 nm. The reflectivity forms a surface over wavelength and composition (Fig. 2a). It is seen that the steep absorption edge that is the source of the color of gold is reduced and displaced towards the short-wavelength region as the amount of silver in the alloy increases. Qualitatively, it would appear that the color of gold will be suppressed for silver contents equal to or above 50 at.% Ag.

Estimated reflectivity of Au-Ag alloys: a the reflectivity surface; b sections through (a) for Au, Au0.9Ag0.1, Au0.7Ag0.3, Au0.5Ag0.5, Au0.3Ag0.7, and Ag; c modification of the Au0.5Ag0.5 reflectivity curve using empirical bowing constants; d modification of the Au0.3Ag0.7 reflectivity curve using empirical bowing constants

Sections through this surface parallel to the wavelength axis, for any fixed composition x, give reflectivity versus wavelength curves. These are plotted for x = 0.3, 0.5, 0.7, and 0.9 (Fig. 2b). The calculated reflectivity curves for Ag-Au alloys lie between those of the parent metals and are well ordered, with a smooth progression from pure gold to pure silver with no exceptions. The absorption edge moves progressively away from that of pure gold towards the low wavelength end of the visible as the amount of silver in the alloy increases. In addition the change in reflectivity of the alloy, ΔR, across the absorption edge decreases significantly. For pure gold, the calculated change in reflectivity is from 0.842 at 550 nm to 0.386 at 450 nm, giving a value for ΔR of 0.456, while for Au0.9Ag0.1 ΔR = 0.441, for Au0.7Ag0.3 ΔR = 0.393, for Au0.5Ag0.5 ΔR = 0.319, and for Au0.3Ag0.7 ΔR has fallen to 0.221. This would equate to a significant whitening of the alloy compared to the color of pure gold, as is found experimentally.

It would be possible to conclude that even at this level of approximation the optical constants of the alloy are reasonably well represented by Eq. 1 over much of the wavelength interval studied. The calculated curves are in fair agreement with those reported previously [6, 7, 18], with one proviso, discussed below.

The exception to this generalization comes at the low and high wavelength ends of the range. The experimentally determined reflectivity of the alloys Au0.5Ag0.5, Au0.4Ag0.6, Au0.3Ag0.7, and Au0.2Ag0.8 falls below that of pure gold in the wavelength range between 350 and 400 nm. Similarly, the experimentally determined reflectivity of the alloys Au0.5Ag0.5 and Au0.4Ag0.6 falls below that of pure gold in the wavelength range 620–750 nm, (see, i.e., [18], Fig. 10), something not reproduced in the ideal model.

The use of bowing constants is able to correct this. These were estimated, in the first instance, from Eq. 3a, b. The reflectivity of Au0.5Ag0.5 is equal to that of Au at approximately 616 nm [18, Fig. 10]. At this wavelength, the optical constants of the parent metals at 616 nm are [19]:

Hence:

The negative coefficient of b n and the positive coefficient of b k gives rise to a reduction in the reflectivity of the alloy (Fig. 1). Although these values pertain only to the wavelength 616 nm, they have been assumed to be applicable to all wavelengths in the range 350–750 nm, and because of the inherent inaccuracies in the determination of the constants, values of b n = −0.2 and b k = 1.6 have been used to calculate the reflectivity of the alloy Au0.5Ag0.5 (Fig. 2c). The curve is a reasonable fit to the experimental one, especially close to 350 nm, where the calculated reflectivity is approximately 0.26, close to that determined experimentally, but gives a reflectivity of 0.96 at 750 nm, which is rather too high. Adjusting the bowing constants to b n = −1.0 and b k = 1.6 causes the curve to fall slightly so that the reflectivity at 350 nm is now approximately 0.23, somewhat too low, but at 750 nm is 0.92, in agreement with the experimental curve. Clearly, in order to fit to curve at both ends, the value of b n should vary between −0.2 and −1.0 over the wavelength range 350–750 nm, while b k remains constant at 1.6.

Similarly, the reflectivity of the alloy Au0.3Ag0.7 is equal to that of gold at approximately 680 nm [18]. Using Eq. 3a, b and the optical constants appropriate to 680 nm [19]:

Hence:

Approximating these values to b n = −0.1, b k = 2.4 and taking them to be applicable to all wavelengths in the range 350–750 nm allows the reflectivity of the alloy Au0.3Ag0.7 to be determined (Fig. 2d). The agreement with the experimental data [18] is good, although the calculated reflectivity is slightly higher than that measured. As in the previous example, this is easily corrected by making small changes to the bowing constants.

The results for gold–silver alloys indicate that, if experimental information is available that allows the calculation of a pair of bowing constants, the application of Eq. 2 across the visible will give good values for the reflectivity of the alloy over this wavelength range. The bowing constants can also be used to estimate the optical constants of the alloy across the composition and wavelength range explored.

Au-Pt

New experimental spectral reflectivity curves for the homogeneous alloys Au0.98Pt0.02, Au0.95Pt0.05, and Au0.9Pt0.1 are presented in Fig. 3. These show that the alloys with the lowest concentration of platinum follow the curve for pure gold, but a considerable change occurs when the platinum concentration reaches 10 at.%, at which point a much flatter curve is found, indicating that the sharp absorption edge that gives rise to the color of pure gold is now almost obliterated.

The ideal reflectivity values calculated for AuxPt1-x with x taking values of 0 to 1 in steps of 0.1 were determined using Eq. 1 and the optical constants of gold and platinum given in Table 1, between the wavelengths of 350 and 750 nm. The results are plotted as a reflectivity surface (Fig. 4a), and the reflectivity versus wavelength (sections through this surface) are shown for x = 0.95, 0.9 and 0.5 (Fig. 4b). The curve for Au0.95Pt0.05 and Au0.98Pt0.02 (the latter is not plotted for clarity, but lies between that of pure gold and the Au0.95Pt0.05 curve shown) are close to that for pure gold.

The change in reflectivity, ΔR, between 450 and 550 nm, across the gold absorption edge, is approximately 0.456 for pure gold, while for Au0.95Pt0.05 ΔR = 0.415, for Au0.9Pt0.1 ΔR = 0.337, and for Au0.5Pt0.5 ΔR has fallen to 0.172. The experimental values (Fig. 3) are approximately 0.28 for Au0.95Pt0.05 and 0.16 for Au0.9Pt0.1. These figures indicate that the alloy has flatter reflectance curves and a much reduced absorption edge compared with that predicted by an ideal mixing. Indeed, experimental reflectivity of Au0.9Pt0.1 falls below that of pure gold and platinum for wavelengths between approximately 520 and 650 nm, and the ΔR value is similar to that computed for ideal Au0.5Pt0.5. Thus, although the ideal reflectivity curves mirror the behavior of the real alloys, the decolorizing effect of Pt is much greater than the ideal calculations suggest.

To reproduce this behavior, bowing constants were estimated in the same way as in the case of Au-Ag. Experimental curves (Fig. 3) show that the reflectivity of Au0.9Pt0.1 is equal to that of pure Pt at approximately 650 nm. Using Eq. 3a’, b’ and the data for the optical constants of the parent metals at 650 nm (Table 1) leads to:

The negative coefficient of b n drops the reflectivity considerably, and this is tuned in the opposite direction by the negative value of b k . Although these values pertain only to the wavelength 650 nm, they have been approximated to −22.0 and −11.0, assumed to be applicable to all wavelengths in the range 350–750 nm and used to calculate the reflectivity of the alloy Au0.9Pt0.1 (Fig. 4c). It is clear that the curve is too flat compared with the experimental curve. The change in reflectivity, ΔR, across the wavelength range 550–450 nm, is 0.10 compared with the experimental value of approximately 0.16.

To attempt to improve on this result, it is possible to use the fact that the experimental reflectivity curve for Au0.9Pt0.1 crosses the curve for pure gold at 515 nm. Using Eq. 3a, b and the optical constants appropriate to 515 nm [19]:

Hence:

Approximating these values to b n = 1.55, b k = 1.59 and taking them to be applicable to all wavelengths in the range 350–750 nm allows the reflectivity of the alloy to be calculated. The values of b n and b k almost cancel each other, and the curve that results is very close to the ideal curve with b n = b k = 0. The reflectivity change is similar to that for the ideal curves given above.

In view of these results, approximately average values of the two sets of bowing constants were used, that is, b n = −10.0 and b k = −5.0. The agreement with the experimental data is now good, especially close to 750 nm, where the calculated and experimental reflectivity are both close to 0.82. The change in reflectivity, ΔR, is now 0.2 compared with 0.16 experimental and the steep absorption edge characteristic of gold has now been suppressed, in agreement with the observed decolorizing effect of Pt (Fig. 4d).

The fit of the calculated reflectivity near to 350 nm is not as good as at 750 nm, as the calculated reflectivity is equal to 0.44 while the experimental reflectivity is approximately 0.38. However, the experimental reflectivity is equal to the calculated ideal reflectivity, indicating that the calculated reflectivity would fit the experimental data if b n and b k are set to 0. An improved correlation between the experimental and calculated reflectivity values will be obtained if the bowing constants are assumed to vary systematically across the wavelength range from b n = b k = 0 at 350 nm to b n = −10.0, b k = −5.0 at 750 nm.

Broadly speaking, these results indicate that, if any experimental results allow empirical bowing constants to be estimated, it is possible to reproduce the reflectivity of these alloys. In addition, the bowing constants allow the optical constants of the alloy to be estimated.

Au-Pd

The reflectivity of homogeneous alloys AuxPd1-x, with x taking values of 0 to 1 in steps of 0.1, were determined using Eq. 1 and the optical constants of gold and palladium given in Table 1, between the wavelengths of 350 and 750 nm. The reflectivity forms a surface over wavelength and composition (Fig. 5a). It is seen that the steep absorption edge that is the source of the color of gold is significantly reduced as the amount of palladium in the alloy increases. Sections through this surface parallel to the wavelength axis for Au0.9Pd0.1, Au0.5Pd0.5, and Au0.3Pd0.7 are given in Fig. 5b.

These curves are very similar to those for platinum in that the absorption edge of the Au component is greatly reduced compared with that for pure gold. For example, the calculated change in reflectivity, ΔR, from 550 to 450 nm, is 0.456 for pure gold, while for Au0.9Pd0.1 ΔR = 0.388, Au0.5Pd0.5 ΔR = 0.189, and for Au0.3Pd0.7 ΔR = 0.120. This would equate to a significant whitening of the alloy compared with the color of pure gold, and as the ideal curves for platinum and palladium are very similar, it is possible to conclude that these metals have an almost identical decolorizing effect in alloys.

The only experimental data that have been located for Au-Pd alloys are given in the reference [6, Fig. 3]. This shows that the reflectivity curves of the Au-Pd alloys studied and the pure metals cross at approximately 515 nm (~2.4 eV), in good agreement with the ideal curves (Fig. 5b). The experimental curves also fall below the curve for pure gold at wavelengths close to 350 nm (~3.5 eV), as is the case with Au-Ag alloys. Once again, this can be modelled by extracting empirical bowing constants from the experimental results as for Au-Ag and Au-Pt if required.

Conclusions

Although the ideal results do not exactly mimic the experimental reflectivity curves where these are available, a comparison between them (Figs. 2a, b; 4a, b; and 5a, b) gives an internally consistent overview of relative alloy reflectivity. The addition of all three metals (silver, platinum, palladium) to gold significantly changes reflectivity curves near the gold absorption edge and indicates that a decolorizing effect occurs. The extent to which the alloy will (subjectively) appear white to the eye will depend upon the flatness of the reflectivity curves and the steepness in the 450–550 nm range. It is seen that the great flattening of reflectivity curve in the visible spectrum is instigated by the addition of platinum and palladium. These metals have an almost identical decolorizing effect in gold alloys. Silver is much more benign in this respect, as can be seen by comparing especially the Au0.5 M0.5 reflectivity curves for the three metals.

These results suggest that it is possible to obtain reasonable (ideal) estimates for the relative reflectivity of homogeneous alloys from the readily available optical constants of the parent metals, even in the absence of any experimental data. As such, this is useful because the optical constants of many alloys are unknown. When experimental reflectivity information is available, it is possible to improve the fit between calculated and experimental data by the estimation of empirical bowing constants that describe the deviation of the optical constants of the alloy from the ideal values obtained from the parent metals. In addition, it is possible to use the results to obtain optical constants of the alloys in the absence of any measurements.

References

Phillips RW (1991) Skinner’s science of dental materials, 9th edn. Saunders WB, Philadelphia, p 365

German RM (1982) Precious-metal dental casting alloys. Int Metals Rev 27:260–288

Powers JM, Sakaguchi RL (eds) (2006) Craig’s restorative dental materials, 12th edn. Mosby Elsevier, St. Louis, pp 470–472

Shiraishi T, Ohta M (2002) Age-hardening behaviors and grain boundary discontinuous precipitation in a Pd-free gold alloy for porcelain bonding. J Mater Sci Mater Med 13:979–983

Loebich O (1972) The optical properties of gold. Gold Bull 5:2–10

Saeger KE, Rodies J (1977) The colour of gold and its alloys. Gold Bull 10:10–14

Roberts EFI, Clarke KM (1979) The colour characteristics of gold alloys. Gold Bull 12:9–19

Roberts EFI, Clarke KM, Hunt R (1980) Optical properties of alloys. Mater Sci Eng 42:71–80

Shiraishi T, Geis-Gerstorfer J (2006) Optical properties of Au-Pt-Pd-based high noble dental alloys. Gold Bull 39:9–15

Normandeau G (1992) White golds: a review of commercial material characteristics and alloy design alternatives. Gold Bull 25:94–103

Corti CW (2005) What is a white gold? Progress on the issues! in Bell E ed. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, p 103–119

Lozano XL, Mottet C, Weissker H-C (2013) Effect of alloying on the optical properties of Ag-Au nanoparticles. J Phys Chem C 117:3062–3068

Massalski TB ed. in chief (1992) Binary alloy phase diagrams, 2nd edn. ASM International, Materials Park, Ohio

Villars P, Prince A, Okamoto H (eds) (1996) Handbook of ternary alloy phase diagrams. ASM International, Materials Park

Bunn CW (1961) Chemical crystallography, 2nd edn. Oxford University Press, Oxford, p 451

Dean JA (ed) (1985) Lange’s handbook of chemistry, 13th edn. McGraw-Hill, New York, pp 10.93–10.94

Tilley RJD (2011) Colour and the optical properties of materials, 2nd edn. John Wiley & Sons, Chichester, pp 60–63

Shiraishi T, Takuma Y, Fujita T, Miura E, Hisatsune K (2009) Optical properties and microstructures of Pd-free Ag-Au-Pt-Cu dental alloys. J Mater Sci 44:2796–2804

Palik ED (1985) Handbook of optical constants of solids. Academic Press, Orlando

Refractive index database http://refractiveindex.info. Accessed 1 August 2013

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Shiraishi, T., Tilley, R.J.D. An estimation of the reflectivity of some monophasic binary gold alloys. Gold Bull 47, 75–82 (2014). https://doi.org/10.1007/s13404-013-0124-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-013-0124-7