Abstract

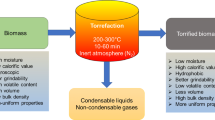

Torrefaction is a thermochemical pretreatment process at 200–300 °C in an inert condition which transforms biomass into a relatively superior handling, milling, co-firing and clean renewable energy into solid biofuel. This increases the energy density, water resistance and grindability of biomass and makes it safe from biological degradation which ultimately makes easy and economical on transportation and storing of the torrefied products. Torrefied biomass is considered as improved version than the current wood pellet products and an environmentally friendly future alternative for coal. Torrefaction carries devolatilisation, depolymerization and carbonization of lignocellulose components and generates a brown to black solid biomass as a productive output with water, organics, lipids, alkalis, SiO2, CO2, CO and CH4. During this process, 70 % of the mass is retained as a solid product, and retains 90 % of the initial energy content. The torrefied product is then shaped into pellets or briquettes that pack much more energy density than regular wood pellets. These properties minimize on the difference in combustion characteristics between biomass and coal that bring a huge possibility of direct firing of biomass in an existing coal-fired plant. Researchers are trying to find a solution to fire/co-fire torrefied biomass instead of coal in an existing coal-fired based boiler with minimum modifications and expenditures. Currently available torrefied technologies are basically designed and tested for woody biomass so further research is required to address on utilization of the agricultural biomass with technically and economically viable. This review covers the torrefaction technologies, its’ applications, current status and future recommendations for further study.

Similar content being viewed by others

Abbreviations

- BO2 :

-

Bio-dioxide (like carbon dioxide)

- CV:

-

Calorific value

- GHG:

-

Green house gas

- LCA:

-

Life cycle analysis

- SCD:

-

Screw conveyors dryers

- TB:

-

Torrefied biomass

- VOC:

-

Volatile organic compounds

References

United Nations (UN). Kyoto protocol to the United Nations framework convention on climate change [Online]. Available at: http://unfccc.int/resource/docs/

Bridgeman TG, Jones JM, Shield I, Williams PT (2008) Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. J Fuels 87:844–856

Bergman, PCA, and Kiel JHA (2005) Torrefaction for biomass upgrading. In: 14th European Biomass Conference & Exhibition, Paris, France, 17–21 October

Paoluccio AJ, Smith RS, Modesto CA (2006) U.S. patent application for “Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and combustible article of manufacture,” Docket no. 60/747,803

Bergman PCA, Boersma AR, Zwart RWH, and Kiel JHA (2005) Torrefaction for biomass co-firing in existing coal-fired power stations. Report ECN-C-05-013, ECN

Kiel JHA (2007) Torrefaction for biomass upgrading into commodity fuels. In: Proceedings of the IEA Bioenergy Task 32 Workshop on Fuel Storage, Handling and Preparation and System Analysis for Biomass Combustion Technologies. Berlin, Germany

Tumuluru JS, Shahab Sokhansanj J, Wright CT, and Boardman RD (2010) Biomass torrefaction process review and moving bed torrefaction system model development. Oak Ridge National Laboratory, INT/EXT-10019569 and INL/CON-10-18636

Chew JJ, Doshi V (2011) Recent advances in biomass pretreatment—torrefaction fundamentals and technology. Renew Sust Energ Rev 15(2011):4212–4222

Tumuluru JS, Sokhansanj S, Hess JR, Wright CT, Boardman RD (2011) A review on biomass torrefaction process and product properties for energy applications. Ind Biotechnol 7:384–401

McKendry P (2002) Energy production from biomass (part1): overview of biomass. Biores Technol 83:37–46

Yang H, Yan R, Chen H, Zheng C, Lee DH, Liang DT (2005) In-depth investigation of biomass pyrolysis based on three major components: hemicellulose, cellulose and lignin. Energy Fuel 20:388–393

Pérez J, Muñoz-Dorado J, Rubia T, Martínez J (2002) Biodegradation and biological treatments of cellulose, hemicellulose and lignin: an overview. Int Microbiol 5(2):53–63

Arias B, Pedida C, Fermoso J, Plaza MG, Rubiera F, Pis JJ (2008) Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process Technol J 89(2):169–175

Bridgeman TG, Jones JM, Williams A, Waldron DJ (2010) An investigation of the grindability of two torrefied energy crops. Fuel J 89(12):3911–3918

Sadaka S, Negi S (2009) Improvements of biomass physical and thermochemical characteristics via torrefaction process. Environ Prog Sustain Energy, AlChE J 28(3):427–434

Jeffries TW (1994) Biodegradation of lignin and hemicelluloses. In: Ratledge C (ed) Biochemistry of microbial degradation. Kluwer, Dordrecht, pp 233–277

Uslu A, Faaij APC, Bergman PCA (2008) Pre-treatment technologies, and their effect on international bioenergy supply chain logistics. Techno-economic evaluation of torrefaction, fast pyrolysis and pelletization. Elsevier Energy 33:1206–1223

Wang G, Luo Y, Deng J, Kuang J, Zhang Y (2011) Pretreatment of biomass by torrefaction. Chin Sci Bull 56:1442–1448

Kiel JHA, Verhoeff F, Gerhauser H, and Meuleman B (2008) BO2 Technology for biomass upgrading into solid fuel-pilot scale testing and market implementation. Energy Research Centre of the Netherlands (ECN), Petten

Repellin V, Govin A, Rolland M, Guyonne R (2010) Energy requirement for fine grinding of torrefied wood. Biomass Bioenergy J 34(7):923–930

Mani S (2010) Integrating biomass torrefaction with thermo-chemical conversion processes. In: Proceedings of the Annual Meeting of AIChE, Nashville, TN. Nov 8–13, 2009, Paper # 160229, [online materials]. http://www.aicheproceedings.org/2009/Fall/data/papers/Paper160229.pdf

Phanphanich M, Mani S (2010) Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Biores Technol J 102(2):1246–1253

Almeida G, Brito JO, Perre P (2010) Alterations in energy properties of eucalyptus wood and bark subjected to torrefaction: the potential of mass loss as a synthetic indicator. Biores Technol J 101(24):9778–9784

Bergman PCA, Boersma AR, Kiel JHA, Prins MJ, Ptasinski KJ, and Janssen FGGJ (2005) Torrefied biomass for entrained-flow gasification of biomass. Report ECN-C--05-026, ECN

Bioenergy Update (2000) vol. 2 No. 4 https://www.bioenergyupdate.com/magazine/security/NL0400/bioenergy_update_april_2000.htm

Govin A, Repellin V, Rolland M, and Duplan J (1988) Effect of torrefaction on grinding energy requirement for thin wood particle production [online materials]. http://hal.archives-ouvertes.fr/docs/00/46/23/39/PDF/AG-SFGP09.pdf

Rousset P, Davrieux F, Macedo L, Perré P (2011) Characterisation of the torrefaction of beech wood using NIRS: combined effects of temperature and duration. Biomass Bioenergy J 35(3):1219–1226

Chen W, Kuo P (2011) Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy J 36(2):803–811

Prins MJ, Ptasinski KJ, Janssen FJJG (2006) More efficient biomass gasification via torrefaction. Energy Fuels J 31(15):3458–3470

Pimchuai A, Dutta A, Basu P (2010) Torrefaction of agricultural residue to enhance combustible properties. Energy Fuel J 24(9):4638–4645

Jenkins BM, Baxter LL, Miles TR Jr (1998) Combustion properties of biomass. Fuel Process Technol 54:17–46

Yan W, Acharjee TC, Coronella CJ, Vásquez VR (2009) Thermal pretreatment of lignocellulosic biomass. Environ Prog Sustain Energy 28:435–440

Waje SS, Patel AK, Thorat BN, Mujumdar AS (2006) An experimental study of the thermal performance of a screw conveyor dryer. Dry Technol 24(3):293–301

Sule I (2012) Torrefaction behaviour of agricultural biomass and their commercial feasibilities, M.A.Sc. Thesis, University of Guelph

Pipatmanomai S (2011) Overview and experiences of biomass fluidized bed gasification in Thailand. J Sustain Energy Environ Spec Issue 29–11

Koukios EG (1993) Progress in thermochemical, solid state refining of biofuels: from research to commercialization. In: Bridgwater AV (ed) Advances in thermochemical biomass conversion, Proceedings of the International Conference, 11–15 May 1992, Vol. 2. Blackie Academic& Professional, London, pp 1678–1693

Ciolkosz D, Wallace R (2011) A review of torrefaction for bioenergy feedstock production. Biofuels Bioprod Bioref. doi:10.1002/bbb.275

Chen W-H, Hsu H-C, Lu K-M, Lee W-J, Lin T-C (2011) Thermal pretreatment of woo(Lauan) block by torrefaction and its influence on the properties of the biomass. Energy 36:3012–3021

Chen W-H, Cheng W-Y, Lu K-M, Huang Y-PA (2011) In evaluation on improvement of pulverized biomass property for solid fuel through torrefaction. Appl Energy 88:3636–3644

Ciolkosz D, Wallace R (2011) A review of torrefaction for bioenergy feedstock production. Biofuels, Bioprod Biorefin 5(3):317–329

Prins MJ, Ptasinski KJ, Janssen FJJG (2006) Torrefaction of wood: part 1. Weight loss kinetics. J Anal Appl Pyrolysis 77:28–34

Van der Stelt MJC, Gerhauser H, Kiel JHA, Ptasinski KJ (2011) Biomass upgrading by torrefaction for the production of biofuels: a review. Biomass Bioenergy 35:3748–e3762

Acharjee TC, Coronella CJ, Vasquez VR (2011) Effect of thermal pretreatment on equilibrium moisture content of lignocellulosic biomass. Biores Technol J 102(7):4849–4854

Bourgeois J, Bartholin MC, Guyonnet R (1989) Thermal treatment of wood: analysis of the obtained product. Wood Sci Technol 23:303–310

Deng J, Wang G-J, Kuang J-H, Zhang Y-L, Luo Y (2009) Pretreatment of agricultural residues for co-gasification via torrefaction. J Anal Appl Pyrolysis 86:331–337

Ferro DT, Vigouroux V, Grimm A, Zanzi R (2004) Torrefaction of agricultural and forest residues. Cubasolar 2004. Guantánamo, Cuba

Felfli FF, Luengo CA, Soler PB, Rocha JD (2004) Mathematical modelling of woods and briquettes torrefaction. In: Proceedings of the 5th Encontro de Energia no Meio Rural, Campinas, Spain, October 19–2. http://www.feagri.unicamp.br/energia/agre2004/Fscommand/PDF/Agrener/Trabalho%205.pdf

Leonelli C, Mason TJ (2010) Microwave and ultrasonic processing: now a realistic option for industry. Chem Eng Process J 49(9):885–900

Amos WA (1998) Report on biomass drying technology. National Renewable Energy Laboratory, report no. NREL/TP-570-25885. http://www.nrel.gov/docs/fy99osti/25885.pdf

Kudra T, Mujumdar AS (2002) Advanced drying technologies. Marcel Dekker, New York, pp 69–70, 81–83, and 335–336

Chandran AN, Rao SS, Varma YBG (1990) Fluidized bed drying of solids. AlChE J 36(1):29–38

Marb CM, Vortmeyer D (1988) Multiple steady states of a cross flow moving bed reactor. Chem Eng Sci 43(4):811–819

Linghong Z, Chunbao CX, Pascale C (2010) Overview of recent advances in thermo-chemical conversion of biomass. Energy 51:969–982

Barrozo MAS, Murata VV, Assis AJ, Freire JT (2006) Modeling of drying in moving bed. Drying Technology 24:269–279

Waje SS, Patel AK, Thorat BN, Mujumdar AS (2007) Study of residence time distribution in a pilot-scale screw conveyor dryer. Dry Technol 25(1):249–259

Tsamba AJ, Yang W, Blasiak W (2006) Pyrolysis characteristics and global kinetics of coconut and cashew nut shells. Fuel Process Technol 87:523–530

Shafizadeh F, Chin Peter PS (1977) Thermal deterioration of wood. Wood technology: chemical aspects. American Chemical Society, Washington, DC, pp 57–81

Shu-de Q, Fang-Zhen G, Dong-li Z (1996) The study on performance of twin screw conveyor. Dry Technol 14(7and 8):1859–1870

De la Hoz A, Díaz-Ortiz A, Moreno A (2005) Microwaves in organic synthesis. Thermal and non-thermal microwave effects. Chem Soc Rev 34:164–178

Miura M, Kaga H, Sakurai A, Kakuchi T, Takahashi K (2004) Rapid pyrolysis of wood block by microwave heating. J Anal Appl Pyrolysis 71:187–199

Salem AA, Ani FN (2011) Microwave induced pyrolysis of oil palm biomass. Biosource Technol J 102(3):3388–3395

Dangtran KY, Mullen JF and Mayrose DT (2000) A comparison of fluid bed and multiple hearth biosolids incineration. In: The 14th Annual Residuals & Sludge Management Conference

FGC Group (2010) http://www.fgcgroupllc.com/multiple_hearth_furnaces.html. Accessed 30 May 2011

Kleinschmidt CP (2011) Overview of international developments in torrefaction. Bio-energy Trade, Torrefaction workshop, http://www.bioenergytrade.org/downloads/grazkleinschmidtpaper2011.pdf

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M et al (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

IEA Bioenergy (2010) Technology roadmaps. International Energy Agency (IEA), Paris

Helwig T, Jannasch R, Samson R, DeMaio A, Caumartin D (2010) Agricultural biomass residue inventories and conversion systems for energy production in Eastern Canada. Prepared for Natural Resources—Canada [online material]. http://www.reapCanada.com/online_library/feedstockbiomass/7Agricultural%20Biomass%20Residue%20Inventories%20and%20Conversion..Samson%20et%20al.%202002.pdf

Dana Mitchell, Tom Elder (2010) Fueling the future. In: 2010 Council on Forest Engineering Annual Meeting June 6–9; Devall Drive, Auburn, Alabama

White RH, Dietenberger MA (2001) Wood products: thermal degradation and fire. In: The encyclopedia of materials: science and technology. Elsevier Applied Science, Amsterdam

Twidell J, Weir T (2005) Biomass and biofuels. In: Renewable energy resources, 2nd edn. Spon, London, pp 351–99

Hakansson K (2007) Torrefaction and gasification of hydrolysis residue. MSc thesis, Umea Institute of Technology

Prins MJ, Ptasinski KJ, Janssen FJJG (2003). Thermodynamics of gas-char reactions: first and second law analysis. Chem Eng Sci 58 (13–16):1003–1011

Josheph J James (2010) Creating power from biomass: torrefaction a key facilitating technology. http://www1.eere.energy.gov/biomass/biomass2010/pdfs/biomass2010_plenary2_james.pdf

Kaliyan N, Vance Morey R (2009) Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 33:337–359

Kumar A, Cameron JB, Flynn PC (2003) Biomass power cost and optimum plant size in Western Canada. Biomass Bioenergy J 24(6):445–464

Nalladurai KR, Vance M (2009) Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 33(3):337–359

Holley CA (1983) The densification of biomass by roll briquetting. In: Proceedings of the Institute for Briquetting and Agglomeration (IBA), Vol. 18, No., pp 95–102

Obernberger I, Thek G (2004) Physical characterization and chemical composition of densified biomass fuels with regard to their combustion behavior. Biomass Bioenergy 27(6):653–669

McMullen J, Fasina OO, Wood CW, Feng Y (2005) Storage and handling characteristics of pellets from poultry litter. Appl Eng Agric 21(4):645–651

Couhert C, Salvador S, Commandré JM (2009) Impact of torrefaction on syngas production from wood. Fuel 88:2286–2290

Kuang X, Tumuluru JS, Bi XT, Lim CJ, Sokhansanj S, Melin S (2009) Rate and peak concentrations of off-gas emissions in stored wood pellets—sensitivities to temperature, relative humidity, and headspace volume. Ann Occup Hyg 53(8):789–796

Zwart RWJ, Boerrigter H, Drift AVD (2006) The impact of biomass pretreatment on the feasibility of overseas biomass conversion to Fischer-Tropsch products. Energy Fuel J 20(5):2192–2197

Svoboda K, Pohořelý M, Hartman M, Martinec J (2009) Pretreatment and feeding of biomass for pressurized entrained flow gasification. Fuel Process Technol J 90(5):629–635

Douglas B (2010) Canada report on bioenergy [Online Material]. http://www.canbio.ca/documents/publications/canadacountryreport2009.pdf

Felfli FF, Luengo CA, Suárez JA, Beatón PA (2005) Wood briquette torrefaction. Energy Sustain Dev 9:19–22

Gilbert P, Ryu C, Sharifi V, Swithenbank J (2009) Effect of process parameters on pelletization of herbaceous crops. Fuel 88:1491–1497

UNEP (2010) Global trends in green energy 2009: new power capacity from renewable sources tops fossil fuels again in US, Europe. REN 21

Lam PS, Sokhansanj S, Bi XT, Lim CJ (2012) Colorimetry applied to steam-treated biomass and pellets made from western Douglas Fir (Pseudotsuga menziesii, L.). Trans ASABE 55(2):673–678

Magalhaes A, Petrovic D, Rodriguez A, Putra Z, Thielemans G (2009) Techno economic assessment of biomass pre-conversion processes as a part of biomass-to-liquids line-up. Biofuels, Bioprod Bioref 3:584–600

Rosillo-Calle F (2007) Biomass assessment handbook—bioenergy for a sustainable environment, 1st edn. Earthscan, London

Rousset P, Turner I, Donnot A, Perré P (2006) The choice of a low temperature pyrolysis model at the microscopic level for use in amacroscopic formulation. Ann For Sci 63:213–229

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Acharya, B., Sule, I. & Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Conv. Bioref. 2, 349–369 (2012). https://doi.org/10.1007/s13399-012-0058-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-012-0058-y