Abstract

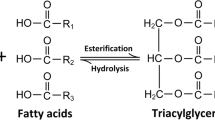

Oil was extracted from the seed of Treculia africana using hexane. The oil was characterized and used in the production of biodiesel. Biodiesel was produced from the seed oil of T. africana using a two-step reaction system. The first step was a pretreatment which involved the use of 2 % sulfuric acid in methanol, and secondly, transesterification reaction using KOH as catalyst. Saponification value of the oil was 201.70 ± 0.20 mg KOH/g, free fatty acid was 8.20 ± 0.50 %, while iodine value was 118.20 ± 0.50 g iodine/100 g. The most dominant fatty acid was C18:2 (44 %). The result of the method applied showed a conversion which has ester content above 98 %, flash point of 131 ± 1.30 °C, and phosphorus content below 1 ppm in the biodiesel. The biodiesel produced exhibited properties that were in agreement with the European standard (EN 14214). This study showed that the high free fatty acid content of T. africana seed oil can be reduced in a one-step pretreatment of esterification reaction using H2SO4 as catalyst.

Similar content being viewed by others

References

Knothe G, Krahl J, Van Gerpen J (2005) The biodiesel handbook. AOCS, Champaign

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Haas MJ, Scott KM, Alleman TL, McCormick RL (2001) Engine performance of biodiesel fuel prepared from soybean soapstock: a high quality renewable fuel produced from a waste feedstock. Energy Fuel 15:1207–1212

Foidl N, Foidl G, Sanchez M, Mittelbach M, Hackel S (1996) Jatropha curcas L. as a source for the production of biofuel in Nicaragua. Bioresour Technol 58:77–82

Zhang Y, Dubé MA, McLean DD, Kates M (2003) Biodiesel production from waste cooking oil: 2. Economic assessment and sensitivity analysis. Bioresour Technol 90:229–240

Akubor PI (1997) Proximate composition and selected functional properties of African breadfruit and sweet potato flour blends. Plant Foods Hum Nutr 51:53–60

Nwokocha LM, Ogunmola GB (2005) Isolation and characterization of starch from Treculia africana, Decne (African breadfruit) seeds. Niger J Sci 39:73–79

Nwokolo E (1987) Nutritional quality of seeds from the African breadfruit (T. africana, Decne). Trop Sci 27:39–47

Ajayi IA (2008) Comparative study of the chemical composition and mineral element content of Artocarpus heterophyllus and Treculia africana. Bioresour Technol 99:5125–5129

Ajiwe VIE, Okeke CA, Agbo HU (1995) Extraction and utilization of breadfruit seed oil. Bioresour Technol 53:183–184

Demirbas A (2003) Biodiesel fuels from vegetable oils via catalytic and noncatalytic supercritical alcohol transesterifications and other methods: a survey. Energy Convers Manag 44:2093–2109

Zhang Y, Dubé MA, McLean DD, Kates M (2003) Biodiesel production from waste cooking oil: 1. Process design and technological assessment. Bioresour Technol 89:1–16

Wang PS, Tat ME, Van Gerpen J (2005) The production of fatty acid isopropyl esters and their use as a diesel engine fuel. J Am Oil Chem Soc 82:845–849

Bryan RM (2009) Biodiesel production, properties, and feedstocks. In Vitro Cell Dev Biol Plant 45:229–266

He DP (2005) Technology of oils and fats refining. Chemical Industry, Beijing

Ajayi IA, Dawodu FA, Adebowale KO, Oderinde RA (2004) A study of the oil content of Nigerian grown Monodora myristica seeds for its nutritional and industrial application. Pak J Ind Res 47:60–65

AOAC (1984) Official methods of analysis, vol 67, 14th edn. Association of Official Analytical Chemist, Arlington

AOCS (2003) American Oil Chemists' Society Official Method Cd 11c-93: quantitative separation of monoglycerides, diglycerides and triglycerides by silica gel column chromatography. p 1–2

American Society for Testing and Material (ASTM) (1998) Standard test method for kinetic viscosity of transparent and opaque liquids. ASTM International, West Conshohocken

AOCS (1997) American Oil Chemists' Society Official Method Ca 14-56: total, free and combined glycerol. p 1–3

American Society for Testing and Material (ASTM) (2004) Copper strip corrosion test D396 specification for fuel oils. p 1–9

AOCS (1997) American Oil Chemists' Society Official Method Cc 9b–55: flash point closed cup method (Modified closed cup method, ASTM designation D 93–80)

AOCS (2002) American Oil Chemists' Society Official Method Ca 12a–02: colorimetric determination of phosphorus content in fats and oils, p 1–4

Ikediobi CO (1981) Amino and fatty acid composition of Pentaclethra macrophyllum and Treculia africana seed. J Am Oil Chem Soc 58:30–31

Gelbard G, Bres O, Vargas RM, Vielfaure F, Schuchardt UF (1995) 1H-Nuclear magnetic resonance determination of the yield of the transesterification of rapeseed oil with methanol. J Am Oil Chem Soc 72:1239–1241

Antolin G, Tinaut FV, Briceno Y, Castano V, Perez C, Ramirez AI (2002) Optimization of biodiesel production by sunflower oil transesterification. Bioresour Technol 83:111–114

Holser RA, O’Kuru RH (2006) Transesterified milkweed (Asclepias) seed oil as a biodiesel fuel. Fuel 85:2106–2110

Ramadhas AS, Jayaraj S, Muraleedharan C (2005) Biodiesel production from high FFA rubber seed oil. Fuel 84:335–340

Hem J, Bryan RM, Joe T, Terry W (2010) Preparation and fuel properties of mixtures of soybean oil methyl and ethyl esters. Biomass Bioenergy 34:14–20

Muhammad T, Saqib A, Fiaz A, Mushtaq A, Muhammad Z, Nasir K, Mir AK (2011) Identification, FT-IR, NMR (1H and 13C) and GC/MS studies of fatty acid methyl esters in biodiesel from rocket seed oil. Fuel Process Technol 92:336–341

Singh SP, Singh D (2010) Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: a review. Renew Sustain Energy Rev 14:200–216

Acknowledgments

The authors are grateful to the Department of Chemistry, University of Ibadan, Nigeria and Indian Institute of Chemical Technology, Hyderabad, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adewuyi, A., Oderinde, R.A. & Ojo, D.F.K. Biodiesel from the seed oil of Treculia africana with high free fatty acid content. Biomass Conv. Bioref. 2, 305–308 (2012). https://doi.org/10.1007/s13399-012-0057-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-012-0057-z