Abstract

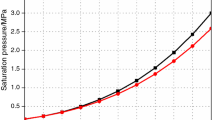

In this paper, cold-room systems in Turkey’s various regions were analyzed as case studies to demonstrate the application of the proposed model. They were also compared with each other in terms of the alteration of alternative refrigerants and insulation thickness and energy and exergy analyses of the cold rooms’ refrigeration system. The coefficients of performance (COP), refrigerant charge rates, volumetric refrigeration capacity and capacities of each component of the refrigeration system for the refrigerants CFC-12, HCFC-22 and their alternatives, such as HFC-134A, HFC-404A, HFC-407C, HFC-410A and HFC-507, were determined by considering the effects of the main parameters of the performance analysis, such as refrigerant type, degree of subcooling, superheating and compressor efficiency. The first law efficiencies, exergy efficiencies and irreversibility rates were also obtained and discussed in this theoretical study. Based on the results of the energy analyses, all the alternative refrigerants have a slightly lower COP and require lower refrigerant charge rates than CFC-12 and HCFC-22 for condensation temperatures ranging from36–47 °C. The investigated large cities in Turkey have an evaporation temperature of −6 °C regarding the preserved product and various ambient temperatures of these largest cities of Turkey range from 31–42 °C in the case studies. Based on the results of the exergy analyses, the compressor has the greatest irreversibility, followed by the expansion valve, condenser and evaporator as the components of the refrigeration system.

Similar content being viewed by others

Abbreviations

- A:

-

Area, m2

- CFCs:

-

Chlorofluorocarbons

- COP:

-

Coefficient of performance

- C p1 :

-

Specific heat for the temperature above the freezing temperature, J kg−1 K−1

- C p3 :

-

Specific heat for the temperature after freezing process, J kg−1 K−1

- E:

-

Exergy rate, kW

- e:

-

Specific exergy, kJ kg−1

- E Q :

-

Rate of exergy of heat input, kW

- E W :

-

Rate of exergy of power output, kW

- F:

-

Defrost factor

- GWP:

-

Global warming potential

- h:

-

Enthalpy, kJ kg−1

- h i :

-

Inner convective heat transfer coefficient, W m−2 K−1

- h d :

-

Outer convective heat transfer coefficient, W m−2 K−1

- H d :

-

Air alteration coefficient

- HCFCs:

-

Hydro chlorofluorocarbons

- HCs:

-

Hydrocarbons

- HFCs:

-

Hydro fluorocarbons

- I:

-

Rate of irreversibility, kW

- k:

-

Thermal conductivity, W m−2 K−1

- K:

-

Total heat transfer coefficient, W m−2 K−1

- L:

-

Length, m

- l:

-

Freezing heat of product, W kg−1

- m:

-

Mass flow rate, kg s−1

- m e :

-

Exergy flow rate of working fluid, kg s−1

- m p :

-

Mass of product, kg

- n eh :

-

Total number of electric heaters in the cold room

- n em :

-

Total number of electric motors in the cold room

- n p :

-

Total number of people in the cold room

- ODP:

-

Ozone depletion potential

- P:

-

Pressure, MPa

- R:

-

Refrigerant

- s:

-

Entropy, kJ kg−1 K−1

- Q:

-

Heat rejection rate, kW

- Q i :

-

Heat generation of a person, kW

- T:

-

Temperature, °C or K

- T 0 :

-

Environmental reference temperature, °C or K

- t 41 :

-

Total working duration of people in the cold room, h

- t 42 :

-

Illumination time for a day, h

- t 43 :

-

Total working time of an electric motor, h

- W:

-

Isentropic compression work, kNm kg−1

- W 1 :

-

Power of illumination, kJ

- W 2 :

-

Power of electric motors, kJ

- W 3 :

-

Power of electric heaters, kJ

- ΔT :

-

Temperature difference, K

- ρ :

-

Density, kg m−3

- η :

-

Efficiency

- δ :

-

Efficiency defects

- afp:

-

After freezing point of product

- cl:

-

Ceiling

- CL:

-

Cooling load

- CR:

-

Cold room

- comp:

-

Compressor

- cond:

-

Condensing/condenser

- E:

-

Exergy

- evap:

-

Evaporating/evaporator

- fl:

-

Floor

- fp:

-

Freezing point

- gen:

-

Generation

- in:

-

Inside

- out:

-

Outside

- T:

-

Total

- tv:

-

Throttling valve

- 1:

-

Evaporator superheat

- 2:

-

Compressorsuperheat

- 3:

-

Condensersaturated liquid

- 4:

-

Evaporator saturated mixture

References

Lee Y.S., Su C.C.: Experimental studies of isobutane (R600a) as the refrigerant in domestic refrigeration system. Appl. Thermal Eng. 22, 507–519 (2002)

Devotta S., Gopichand S., Pendyola V.R.: Assessment of HFCs, fluorinated ethers and amine as alternatives to CFC 12. Int. J. Refrig. 16, 84–89 (1993)

Wongwises S., Kamboon A., Orachon B.: Experimental investigation of hydrocarbon mixtures to replace HFC-134a in an automotive air conditioning system. Energy Convers. Manag. 47, 1644–1659 (2006)

Wongwises S., Chimres N.: Experimental study of hydrocarbon mixtures to replace HFC-134a in a domestic refrigerator. Energy Convers. Manag. 46, 85–100 (2005)

Wongwises S., Pirompak W.: Flow characteristics of pure refrigerants and refrigerant mixtures in adiabatic capillary tubes. Appl. Thermal Eng. 21, 845–861 (2001)

Wongwiscs S., Songnetichaovalit T., Lokathada N., Kritsadathikarn P., Suchatawat M., Pirompak W.: A comparison of the flow characteristics of refrigerants flowing through adiabatic capillary tubes. Int. Commun. Heat Mass Transf. 27, 611–621 (2000)

Dalkilic A.S., Wongwises S.: A performance comparison of vapour-compression refrigeration system using various alternative refrigerants. Int. Commun. Heat Mass Transf. 37(9), 1340–1349 (2010)

Dalkilic, A.S.; Wongwises, S.: Comparison of various alternative refrigerants for vapour compression refrigeration systems. In: Proceedings of the ASME/JSME 8th Thermal Engineering Joint Conference, March 13–17, USA (2011)

Dalkilic, A.S.: Theoretical analysis on the prediction of performance coefficient of two-stage cascade refrigeration system using various alternative refrigerants. Isi BilimiveTeknigiDergisi/J. Thermal Sci. Technol. (2012) (in Press)

Dopazo J.A., Fernández-Seara J., Sieres J., Uhía F.J.: Theoretical analysis of a CO2–NH3 cascade refrigeration system for cooling applications at low temperatures. Appl. Thermal Eng. 29, 1577–1583 (2009)

Lee Y.S., Su C.C.: Experimental studies of isobutane (R600a) as the refrigerant in domestic refrigeration system. Appl. Thermal Eng. 22, 507–519 (2002)

Kanoǧlu M.: Exergy analysis of multistage cascade refrigeration cycle used for natural gas liquefaction. Int. J. Energy Res. 26, 763–774 (2002)

Cengel Y., Boles M.A.: Thermodynamics—An Engineering Approach. McGraw-Hill, New York (2010)

REFPROP, Thermodynamic properties of refrigerants and refrigerant mixtures, version 7, Gaithersburg, M.D. National Institute of Standards and Technology (2001)

SOLKANE Refrigerant software, version 7, Hannover, Solvay Fluor Gmbh (2010)

Duruk, A.M.; Sarıbatı, Ş.: Soǧutmatesisatı TMMOB, publication number MMO/295-2 (2002)

Özkol, N.: Uygulamalısoǧutmatekniǧi, TMMOB, publication number MMO/115-7 (1999)

Stegou-Sagia A., Paignigiannis N.: Evaluation of mixtures efficiency in refrigerating systems. Energy Convers. Manag. 46, 2787–2802 (2005)

Arcaklıoglu E., Cavusoglu A., Erisen A.: Thermodynamic analysis of refrigerant mixtures for possible replacements for CFCs by an algorithm compiling property data. Appl. Thermal Eng. 26, 430–439 (2006)

Kopac M., Zehmer B.: Effect of saturation-temperature on the performance of a vapour-compression refrigeration-cycle working on different refrigerants using exergy method. Int. J. Energy Res. 30, 729–740 (2006)

Bejan A.: Advanced Engineering Thermodynamics, 3rd edn. Wiley, Hoboken (2006)

Bejan A.: Entropy Generation Minimization. CRC Press, Boca Raton (1996)

Stegou-Sagia A., Paignigiannia N.: Exergy losses in refrigerating systems. A study for performance comparisons in compressor and condenser. Int. J. Energy Res. 27, 1067–1078 (2003)

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Dalkilic, A.S., Kurekci, N.A., Kincay, O. et al. Fundamental Basis and Application of Cold-Room Project Design: A Turkish Case Study. Arab J Sci Eng 38, 1115–1130 (2013). https://doi.org/10.1007/s13369-012-0534-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-012-0534-5