Abstract

Separation of carrier-free iodine from low-level iodine samples and accurate measurement of ultra-low-level 129I in microgram iodine target are essential but a bottleneck in geology and environment research using naturally produced 129I. This article presents a detection technique of accelerator mass spectrometry (AMS) for accurate determination of ultra-low-level 129I in carrier-free AgI-AgCl sputter targets. Copper instead of aluminum was selected as the suitable sample holder material to avoid the reaction of AgI-AgCl powder with aluminum. Niobium powder was selected as thermally and electrically conductive matrix to be mixed with AgI-AgCl powder, in order to obtain and maintain a stable and high iodine ion current intensity, as well as less memory effect and low background level of 129I. The most optimal ratio of the Nb matrix to the AgI-AgCl powder was found to be 5:1 by mass. The typical current of 127I5+ using AgI-AgCl targets with iodine content from 5 to 80 μg was measured to be 5 to 100 nA. Four-year AMS measurements of the 129I/127I ratios in standards of low iodine content and the machine blanks showed a good repeatability and stability.

ᅟ

Similar content being viewed by others

Introduction

The naturally occurring isotopes of iodine are stable 127I and long-lived radioactive 129I with a half-life of 15.7 Ma. 129I is naturally produced mainly through reactions of cosmic rays with xenon in the upper atmosphere, spontaneous fission of 238U, and thermal neutron-induced fission of 235U in the earth. Owing to the strong association of iodine with organic material and the constant production of 129I in the terrestrial environment, 129I is an ideal tracer for environmental processes and geological age dating up to 80 Ma [1–7]. For this purpose, the pre-anthropogenic 129I/127I atomic ratio in geological samples (i.e., the initial value of the 129I/127I ratio in different environmental reservoirs) has to be determined [3, 5, 6, 8]. Investigations have been carried out on terrestrial environmental samples collected before 1940 or on underground samples, but the reported pre-nuclear 129I/127I ratios in terrestrial samples varied considerably from 5 × 10–12 to 1 × 10–9, which probably result from unsuitable analytical methods, sample storage, and treatment processes [1, 9, 10].

Accelerator mass spectrometry (AMS) is the most sensitive technique to detect 129I and the only method for measurement of 129I in pre-nuclear age samples with 129I/127I atomic ratios <10-10 [11, 12]. AMS, as a relative measurement method, can only provide the 129I/127I ratios. The reliable determination of the 129I activity thus also depends on the 127I signal, which related to the amount of stable 127I loaded into the target. Typically, 0.5 to 5 mg iodine (usually in AgI form) are needed to obtain a reliable AMS measurement. Because the concentration of iodine in environmental and geological samples is normally relative low, iodine carrier was often added to be able to obtain a sufficient amount of iodine for AMS measurement. However, as 129I always exists in the 127I carrier, addition of a large amount of carrier will interfere with the determination of low-level 129I in the samples. Separation and AMS measurement of low-level 129I in carrier-free targets will be an ideal solution.

Yiou et al. [13] reported a carrier-free method to separate microgram iodine by adsorption of iodine on fine Ag powder, and used it for analysis of seawater samples from the present environment. Hou et al. reported another method for separation of carrier-free iodine by co-precipitation of AgI with silver chloride (AgCl), the method has been applied for measurement of 129I in various environmental and geological samples, including water, soil, and rock [14]. A satisfactory recovery of iodine (>70%) was obtained for various types of samples. Lu [11] investigated the influence of the iodine mass on the accuracy of the 129I/127I ratio measurement in the AMS system at PRIME Lab at the Purdue University, and claimed that more than 0.1 mg AgI is needed to obtain a reliable 129I/I ratio. Owing to the low iodine concentration in most terrestrial samples, the separated iodine in the final sputter target is typically less than 0.1 mg. Zhang et al. [15] have discussed the detection limit and the analytical uncertainty of this method. The estimated minimum amount of iodine required to obtain reliable analytical results was as small as 5 μg for analyzing samples with 129I/127I > 10−12. This work aims to present some important issues for reliable AMS measurement of 129I in AgI-AgCl targets prepared from low-level iodine samples using the carrier-free preparation method.

Experimental

Targets Preparation for Evaluating Influence of the Iodine Content on the 129I/127I Measurement

Four sets samples with different but known 129I/127I atomic ratios were prepared to evaluate the influence of iodine content in the target holder on the measurement of the 129I/127I ratio. Each set of samples contains eight types of targets with different iodine content, which were prepared by addition of different amounts of NaCl solution to a certain amount of 129I/127I standard solution to obtain different mass ratios of Cl:I (0.45–100) in the solution. The 129I/127I standard solutions were prepared by dilution of the 129I standard NIST-SRM 4949c (National Institute of Standards and Technology, USA) using 127I– solution prepared from an iodine crystal (Woodward Inc., Oklahoma, USA) in which the 129I/127I is < 2.0 × 10–13). An excess amount of AgNO3 solution was added to the prepared standard solution, the formed AgI-AgCl precipitate was separated by centrifuge, and then dried at 60°C for 3–4 h. After being ground to a fine powder, the precipitate was mixed with metal powder in a mass ratio of 1:5; the mixture was then packed into target holders for the AMS measurement. The 129I/127I ratio and the iodine content in each holder are listed in Table 1. The seventh sample of each set with Cl:I ratio of 1:1 was also used for evaluate the performance of the metal matrix.

The machine blanks were prepared by pressing only Nb powder into the target holders, and they were inserted in the AMS measurement sequence immediately after the targets of high 129I/127I atomic ratio in each batch to monitor the memory effect and the background of the instrument.

Investigation of the Influence of Matrix Materials and Mixture Ratio of Sample to Matrix

Four types of metals were investigated for their performance as matrix materials for AMS measurement of 129I, including niobium powder (325 mesh; 99.99%; Alfa Aesar, GmbH & Co. KG, a Johnson Matthey Company, Karlsruhe, Germany), silver powder (325 mesh; 99.99%; Alfa Aesar, GmbH & Co. KG, a Johnson Matthey Company), copper powder (size <63 μm (>230 mesh ASTM), >99.7%, Merck KGaA, Darmstadt, Germany), and iron powder (325 mesh, 97% purity; Aldrich Chemical, Saint Louis, MO, USA). The AgI-AgCl precipitate with the lowest 129I/127I ratio of <2.0 × 10–13 was mixed with different types of metal matrices in a mass ratio of 1:5, and the mixture was pressed into copper target holders. Performance of each target was investigated by an AMS measurement for 129I and sputtering the target continuously in the ion source for 30 min. The extracted I– current was recorded every 20 s to observe the current intensity and stability. Additional measurements were carried out on targets containing matric metal and AgI-AgCl precipitate of the lowest 129I/127I ratio to check the influence of the matrix on the background level of 129I.

Two sets of AgI-AgCl precipitate with 129I/127I of 9.95 × 10–12 and <2 × 10–13 (both with Cl/I ratio of 1:1) were mixed with different amounts of Nb powder (with mass ratios of metal matrix to sample of 2 to 15), and pressed into copper target holders. A certain volume of Nb and AgI-AgCl precipitate was taken using a capillary tube to a centrifuge tube, which was also weighted using an analytical balance to get the ratio of Nb and AgI-AgCl in volume and mass.

Investigation of the Influence of Materials of Sample Holder

AgI, AgCl, and AgI-AgCl (Cl:I of 1:1 by mass) precipitates were mixed with niobium matrix with a mass ratio of 1:5, the mixtures were then pressed into two types of sample holders made of aluminum and copper. The influence of the holder materials on the stability of the sample target was investigated using a microscope by observing the surface changes with a timeframe from immediately after pressing to 1 week.

Investigation of the Influence of Iodine Mass in Target Holder on the 129I Signal

The mass of the mixture of AgI-AgCl and matrix pressed into the conventional target holder used at the Xi’an AMS center is about 3 mg, and the mass of iodine pressed into the holder is related to both the ratio of AgI-AgCl to matrix and the ratio of Cl/I. When a mass ratio of AgI-AgCl to Nb of 1:5 is applied, the mass of iodine pressed in the targets is about 100 μg for the AgI-AgCl co-precipitate with a Cl/I mass ratio of 1:1. For unknown samples, the mass of carrier Cl– used for co-precipitation is 200 μg. Assuming that the mass ratio Cl/I is between 10:1 and 1:1, the mass in the final target holders are about 10 to 100 μg, depending on the iodine concentration in the raw sample and the sample mass.

129I Measurement Using a 3 MV Tandetron Accelerator Mass Spectrometer in the Xi’an AMS Center

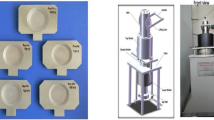

Figure 1 shows a schematic of the Xi’an AMS system; the detailed technical parameters of the instrument have been described elsewhere [16]; the specific features of the instrument for the 129I analysis are presented below.

Schematic of the Xi’an AMS system consisting of four parts. (a) Bouncer injector assembly with SO110 Cs-sputter negative ion source, 54° electrostatic deflector, 90° analyzing magnet with bouncing system, beam-blanking unit etc. (b) Electronic pack, control cabinet, and computer system. (c) Tandetron accelerator assembly with Q-snout, Ar gas stripper, and high energy Q-pole. (d) High energy mass spectrometer assembly with: (1) Steerers assembly; (2) 115° analyzer magnet and Faraday cups with slit-stabilization function for the measurement of stable isotopes; (3) 65° electrostatic deflector assembly; (4) detection table assembly

The iodine isotopes together with other isotopes are ionized and extracted in the Cs-sputter negative ion source [17] with an energy of 35 keV. The negative ion beam is first filtered by an electrostatic deflector to select ions according to their energy, and then by an injector magnet to select ions according to their magnetic rigidity. The selected ions with masses of 129 and 127 are injected sequentially into the accelerator system by switching the bouncer voltage [18] at a frequency of 100 Hz. The injection time of ions with mass 129 (9 ms) is 90 times longer than that of ions with mass 127 (100 μs).

The tandetron accelerator consists of two accelerating sections with a positive high voltage terminal in the middle, which contains argon as stripper gas [19]. For 129I measurements, a voltage of 2.5 MeV is applied. After acceleration in the low-energy end of the accelerator, some shell electrons of the iodine ions are stripped off in the terminal canal. Negative I– is converted into multiply charged positive ions, and all potential interfering polyatomic molecules are broken and removed. The resulting positive iodine ions are accelerated again in the second part of the accelerator.

A magnetic-electrostatic-magnetic high-resolution mass spectrometer following the accelerator provides a high selectivity of ions regarding E/q (energy/charge) and M/q (mass/charge) [16, 20]. The ion beam from the accelerator is first focused using a quadrupole doublet lens to form an object for further separation using a 115° double-focusing magnet with the maximum magnetic field intensity of about 1.14 T. The corresponding mass resolution M/ΔM is 820 for analyzing 129I with all slits adjusted to 4 mm. The charge state +5 is chosen for 129I measurements. The stripping yield of I+5 is measured to be 3.6% to 3.8% in the Xi’an AMS system. After separation in the analyzing magnet, the purified 127I5+ is measured by an off-axis Faraday cup, which is gated and synchronized with the isotope injection time. The usually utilized measurement ranges of the iodine ion current in the Faraday cup are 0–100 nA for AgI-AgCl co-precipitation targets and 0–1 μA for AgI targets. The 129I5+ ion is further filtered using a 65° cylindrical electrostatic analyzer with an energy resolution E/ΔE of 750 and an additional 30° deflection magnet with a mass resolution M/ΔM of 175. The 129I5+ beam is focused by a quadrupole doublet before the 30° magnet, and finally counted by a gas ionization detector.

Results and Discussion

Selection of Cathode Material for AgI-AgCl Co-Precipitate Target

Aluminum material is often used to manufacture target holder for AMS measurements of 14C and 10Be [21, 22]. The aluminum holder has also been used for the AMS measurement of 129I for AgI targets in many laboratories [23, 24]. However our experiment showed that an unstable iodine ion current was observed and the vacuum of the ion source fluctuated dramatically during the AMS measurement of 129I when AgI-AgCl targets were sputtered, which were made by mixing the AgI-AgCl co-precipitate with Nb powder and packed into an aluminum holder. It has been reported that the AgI precipitate deliquesces in air in a few hours after pressing in such holders. Because such samples could not be properly measured or even no beam current could be observed at all, it is suggested that the AgI target should be prepared in a short time before measurement, and the prepared target has to be stored in a desiccator before AMS measurement [23, 24]. For investigation of the stability of AgI and AgI-AgCl precipitate in different target holders, the surface features of the targets were observed under a microscope, after the mixture of precipitate and Nb was pressed into the aluminum and copper holders. A violent reaction (bubbles) was observed shortly (less than 10 min) after AgI-AgCl was pressed into the aluminum holder and exposed to air (Figure 2a). A similar but much weaker reaction was observed for AgI precipitate when it was mixed with Nb powder and pressed into an aluminum holder. Liquid bubbles on the surface of the sample were observed 1 d later for the AgI target (Figure 2b). No visible reaction was observed when they were pressed in holders made of copper for both AgI and AgI-AgCl precipitate, even after exposure to air for more than 7 d (Figure 2c, d). Evidently, copper is a more suitable cathode material for AMS measurements of 129I than aluminum. This result also implies that the unstable feature of AgI-AgCl targets is not attributed to the deliquescence of AgI-AgCl or AgI, but a reaction between AgI-AgCl or AgI with the aluminum holder.

Image of pressed sputter target surfaces of different mixtures observed under the microscope. (a) AgI-AgCl (AgI:AgCl:Nb = 1:1:5 by mass) target, 10 min after being pressed in aluminum holder; (b) AgI (AgI:Nb = 1:5 by mass) target, 1 d after being pressed in aluminum holder. (c) AgI-AgCl mixture (AgI:AgCl:Nb =1:1:5 by mass) target, 7 d after being pressed in copper holder. (d) AgI (AgI:Nb =1:5) target, 7 d after being pressed in copper holder. (e) AgCl (no Nb) target, 30 min after being pressed in aluminum holder. (f) AgI (no Nb) target, 1 d after being pressed in aluminum holder

It has been reported that although a heterogeneous reaction 3AgI + Al = 3Ag + AlI3 is a thermodynamically favored reaction, it does not take place unless both water vapor and water soluble iodide are available (i.e., if the sample is exposed to humid air and some water soluble iodide species is pressed in the AgI precipitate [25]). A rapid reaction of AgCl and AgCl + AgI with the aluminum holder was observed in our experiment (Figure 2a, e), whereas the reaction between AgI and the aluminum holder (Figure 2f) is relatively slow, which might be attributed to the higher solubility product of Ag+ + Cl- = AgCl (Ksp = 1.8 × 10–10) compared with Ag+ + I– = AgI (Ksp = 8.5 × 10–17). With water vapor, AgCl precipitate is more easily converted to chloride than that of AgI to iodide; therefore, the reaction of AgCl and AgCl + AgI with aluminum target takes place rapidly. It has to be mentioned that no reaction occurred when AgI or AgI + AgCl precipitate was simply mixed with Al powder or put on an aluminum sheet, even for more than 2 wk contact time. This implies that a close contact between AgI or AgI + AgCl precipitate with aluminum is needed for such a solid state reaction.

Considering the mechanical properties and cost, we selected copper as holder material for AMS measurements of 129I. This may also be useful for the AMS measurement of 36Cl, in which AgCl was normally prepared as sputter target.

Selection of Metal Matrix

AgI or AgI-AgCl precipitate needs to be mixed with conductive material before being pressed into a target holder in order to avoid charge-up of the target and to remove the heat produced in the target material during Cs+ ion sputtering. Many types of conductive material have been used as matrix material in target preparation for AMS measurement. Copper, silver, iron, and niobium are the most often used materials and are, therefore, selected and investigated in this work. Figure 3a shows the variation of the measured current of iodine ion extracted from targets with the same amount of AgI + AgCl but mixed with different matrix materials. The highest intensity and long-term stability of the I5+ current were observed in the target using Nb powder as matrix.

Figure 3b shows the measured count rate of 129I and 129I/127I atomic ratios in targets with different matrix materials but the same AgI-AgCl precipitate, which was prepared from the lowest 129I/127I ratio standard. The measured average 129I/127I atomic ratios are (4.19 ± 1.83) × 10–13 for iron, (1.15 ± 0.19) × 10–13 for copper, (1.03 ± 0.19) × 10–13 for silver, and (0.73 ± 0.14) × 10–13 for niobium powder as matrix. The target prepared using iron matrix showed a four times higher 129I/127I atomic ratio; this is mainly attributed to the similarly increased signal of 129I count rate in this target compared with the other three matrix materials. This might imply that the iron matrix contains more 129I than the other types of matrix material investigated in this work. The difference among the other three metal materials, silver, copper, and niobium, is barely significant, although the target with niobium as matrix shows the lowest 129I/127I. Considering that the 129I contamination in the matrix materials might also originate from the environment of manufacture and storage, the matrix materials silver, copper, and niobium are of the same quality in view of the background level of 129I. Based on the features of current intensity and stability of iodine ion and the 129I background level, it can be concluded that niobium is the most suitable matrix material for AMS measurements of 129I in AgI-AgCl sputter targets, especially for ultra-low-level 129I measurement.

Due to the unstable chemical property of iodine, the cross contamination or memory effect in AMS is a critical aspect for the accurate measurement of 129I, especially for low level 129I. The results of the Nb blanks inserted in the measurement sequence immediately after the targets with higher 129I content (up to 7 × 107 atoms) or higher 129I/127I ratio (1.14 × 10–10) showed that no increased count rate of 129I was observed in these Nb blanks, confirming no cross contamination between samples. This also indicates that Nb is suitable as matrix material for low-level 129I measurements. In the routine analysis of 129I samples, immediately after potentially high 129I samples, a Nb blank was always inserted in the measurement sequence to monitor the cross contamination, but so far no significant cross contamination has been observed, even for relatively high samples (129I/127I atomic ratio of 5 × 10-9).

The Optimal Mixture Ratio of the Matrix with AgI-AgCl Precipitate

The mixing ratio of the matrix with the AgI-AgCl precipitate is another critical parameter for obtaining a stable iodine ion current and satisfactory sensitivity of the 129I measurement. An insufficient amount of matrix might cause an unstable iodine ion current, whereas an excessive amount of matrix might reduce the iodine ion current and decrease sensitivity.

The variation of the measured 127I5+ currents and 129I/127I atomic ratios in two sets of AgI-AgCl targets with the mixture ratio of niobium matrix to AgI-AgCl from 2 to 15 is shown in Figure 4; the two series of targets have different 129I/127I ratios but the same Cl/I ratio. The results show a peak iodine ion current at the AgI-AgCl to Nb ratio of 1:5 and a decreasing trend of iodine ion current with increasing mixture ratio of niobium to AgI-AgCl precipitate. The measured 129I/127I ratios in targets of set F with 129I/127I = 9.95 × 10–12 remain constant for mass ratios of niobium matrix to AgI-AgCl precipitate of 2 to 7, whereas a decreased iodine ion current was observed for the matrix to precipitate ratios higher than 7. For the targets of set E with 129I/127I < 2 × 10–13, the lowest 129I/127I ratio was measured in the target with the niobium matrix to AgI-AgCl precipitate ratio 1:5. Based on these observations, the optimal ratio of niobium matrix to AgI-AgCl precipitate is 1:5 by mass; this mixture ratio is, therefore, selected for AMS measurements of 129I using AgI-AgCl targets.

Minimum Iodine Loaded into the Target for Accurate Measurement of 129I/127I

Signals down to 1 nA 127I5+ current and 1 cpm 129I can be measured, corresponding to 1 μg 127I and 104 atoms 129I in the target, or a 129I/127I ratio of 2 × 10–12. Therefore, the total iodine loaded into the target is the major factor influencing the minimum detectable 129I/127I ratio. The measurement results of four sets of targets with 129I/127I ratios from <2 × 10–13 to 1.14 × 10–10 and varying iodine load into the target with Cl:I ratio from 0.45 to 100 are shown in Figure 5. It can be seen that for the targets with the same 129I/127I ratio, the measured 129I/127I atomic ratio tends to increase when the iodine load into the target decreased, especially for the target with lower 129I/127I atomic ratio. From the results shown in Figure 5, it can be concluded that the minimum iodine load into the target for accurate measurement of 129I/127I is about 17 μg/mg at the 129I/127I atomic ratio of 2.0 × 10 -13, 7 μg/mg for the 129I/127I ratio of 2.2 × 10 –12, about 2 μg/mg for the 129I/127I ratio of 9.95 × 10 –12, and about 1 μg/mg for the 129I/127I ratio of 1.14 × 10 –10 . Based on these results and the iodine concentration in the samples, the minimum sample amount required for the measurement of 129 I/ 127 I at a certain level can then be calculated.

AMS Batch Measurement of 129I in Carrier-Free AgI-AgCl Targets

One of the major challenges for AMS measurements of 129I in carrier-free AgI-AgCl targets is the accurate measurement of the I5+ current because of the low iodine content in the target. All four image slits were set to 4 mm to restrain the interfering ions and to get an optimal resolution. Owing to the low iodine ion current in the AgI-AgCl target, all analyzers were first tuned using an ordinary AgI standard target with more than 200 μg iodine to obtain suitable measurement parameters, afterwards adjusted by fine-tuning using AgI-AgCl standard targets of well-known 129I/127I ratio. The typical current of 127I5+ in an AgI-AgCl target is 5 to 80 nA, which can be precisely measured using the Faraday cup in the 0–100 nA range. 127I5+ currents of 0.1–0.3 nA and 129I5+ count rate of 0–1 counts/min (average 0.4 counts/min) were usually measured in the instrument blanks (only Nb powder). Based on these data, 10 times the signal of the blank (i.e., 3 nA for the I5+ current and 4 counts/min for the 129I count rate) were set as the threshold for obtaining a reliable AMS result. In general, each batch of AMS samples consists of 2 AgI standards for machine tuning, 3 AgI-AgCl standard targets with 129I/127I atomic ratio of 1.14 × 10–10, 3 AgI-AgCl standard targets with 129I/127I atomic ratio of 9.95 × 10–12, 3 Nb targets as machine blanks, 2 to 4 procedure blanks of AgI-AgCl targets, and 34 to 36 AgI-AgCl sample targets. Each target is measured for 5 min in each cycle, and at least six cycles of measurements were carried out for each batch. The 129I/127I ratios are averaged and then normalized using the 129I/127I ratio of AgI-AgCl standard. The AgI-AgCl standard targets were also used for cross-checking the stability of the whole AMS system.

Reliability and Repeatability of AMS Measurement of 129I in Carrier-Free Iodine Targets

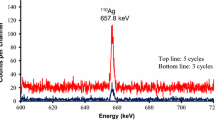

The analytical accuracy, precision, detection limit, and the least sample amount for determination of 129I/127I in samples with low-level iodine in the AgI-AgCl target have been discussed in [15]. It has been confirmed that the AMS measurement of 129I in AgI-AgCl targets prepared by the carrier-free method can provide a reliable and accurate result if a suitable amount of iodine is separated from the sample and pressed into the holder. In the past 4 y, 26 batches of samples with a total of 744 ultra-low-level iodine targets have been measured, which include 100 standards with 129I/127I atomic ratio of 1.14 × 10–10 and 103 machine blank (only Nb powder). Figure 6a shows the normalized 129I/127I ratios of all standards with the 129I/127I atomic ratio of 1.14 × 10–10; the measured values agree with the prepared value within 5% uncertainty, which was relatively constant. The 129I count rate of all machine blanks measured in the past 4 y (Figure 6) vary from 0.0 to 1.4 counts/min, which is relatively low for 129I-AMS measurements. The only abnormal fluctuation of the 129I/127I atomic ratio in standards occurred during February and April, 2013, which might be due to an SF6 leakage to the accelerator vacuum, which also has led to an increase of signals on the machine blank.

Conclusions

Based on the discussion above, it can be concluded that (1) copper is a suitable sputter target holder material for AMS measurements of 129I, especially for targets of AgI-AgCl, chemical reaction between AgCl (AgI), and that aluminum holder in air causes formation of a liquid-like compound that is responsible for the failure of measurements or unstable iodine ion current; (2) among four types of metal matrices, Nb powder is the best in view of maintaining stable and higher iodine ion current intensity and less background signals; (3) the optimal mixture ratio of the Nb matrix to the AgI-AgCl target is 5:1 by mass; (4) the smallest iodine content in the target holder is estimated as: 50 μg at the 129I/127I atomic ratio of 2.0 × 10–13, 20 μg for an 129I/127I ratio of 2 × 10–12, 6 μg for an 129I/127I ratio of 1 × 10–11, and 3 μg for an 129I/127I ratio of 1 × 10–10.

References

Fehn, U., Snyder, G., Egeberg, P.K.: Dating of pore waters with 129I: relevance for the origin of marine gas hydrates. Science 289, 2332–2335 (2000)

Fan, Y., Hou, X., Zhou, W.: Progress on 129I analysis and its application in environmental and geological researches. Desalination 321, 32–46 (2013)

Fehn, U., Snyder, G.T., Muramatsu, Y.: Iodine as a tracer of organic material: 129I results from gas hydrate systems and fore arc fluids. J. Geochem. Explor. 95, 66–80 (2007)

Fehn, U., Moran, J.E., Teng, R.T.D., Rao, U.: Dating and tracing of fluids using 129I and 36Cl: results from geothermal fluids, oil field brines, and formation waters. Nucl. Instrum. Methods Phys. Res., Sect. B 92, 380–384 (1994)

Fabryka-Martin, J., Davis, S.N., Elmore, D.: Applications of 129I and 36Cl in hydrology. Nucl. Instrum. Methods Phys. Res., Sect. B 29, 361–371 (1987)

Fabryka-Martin, J., Bentley, H., Elmore, D., Airey, P.L.: Natural iodine-129 as an environmental tracer. Geochim. Cosmochim. Acta 49, 337–347 (1985)

Hou, X., Hansen, V., Aldahan, A., Possnert, G., Lind, O.C., Lujaniene, G.: A review on speciation of iodine-129 in the environmental and biological samples. Anal. Chim. Acta 632, 181–196 (2009)

Fehn, U., Moran, J.E., Snyder, G.T., Muramatsu, Y.: The initial 129I/I ratio and the presence of ‘old’ iodine in continental margins. Nucl. Instrum. Methods Phys. Res., Sect. B 259, 496–502 (2007)

Szidat, S., Schmidt, A., Handl, J., Jakob, D., Botsch, W., Michel, R., Synal, H.A., Schnabel, C., Suter, M., López-Gutiérrez, J.M., Städe, W.: Iodine-129: sample preparation, quality control, and analyses of pre-nuclear materials and of natural waters from Lower Saxony, Germany. Nucl. Instrum. Methods Phys. Res., Sect. B 172, 699–710 (2000)

Wallner, G., Steier, P., Brandl, T., Friesacher, M.E., Hille, P., Kutschera, W., Tatzber, M., Ayromlou, S.: Developments toward the measurement of I-129 in lignite. Nucl. Instrum. Methods Phys. Res., Sect. B 259, 714–720 (2007)

Lu, Z., Fehn, U., Tomaru, H., Elmore, D., Ma, X.: Reliability of 129I/I ratios produced from small sample masses. Nucl. Instrum. Methods Phys. Res., Sect. B 259, 359–364 (2007)

Hou, X., Roos, P.: Critical comparison of radiometric and mass spectrometric methods for the determination of radionuclides in environmental, biological and nuclear waste samples. Anal. Chim. Acta 608, 105–139 (2008)

Yiou, F., Diel, K., Martin, F.-X., Raisbeck, G.: Preparation of microgram quantities of carrier-free iodine for AMS analysis. Nucl. Instrum. Methods Phys. Res., Sect. B 172, 395–398 (2000)

Hou, X., Zhou, W., Chen, N., Zhang, L., Liu, Q., Luo, M., Fan, Y., Liang, W., Fu, Y.: Determination of ultralow level 129I/127I in natural samples by separation of microgram carrier-free iodine and accelerator mass spectrometry detection. Anal. Chem. 82, 7713–7721 (2010)

Zhang, L., Hou, X., Zhou, W., Chen, N., Liu, Q., Luo, M., Fan, Y., Fu, Y.: Performance of accelerator mass spectrometry for 129I using AgI–AgCl carrier-free co-precipitation. Nucl. Instrum. Methods Phys. Res., Sect. B 294, 276–280 (2013)

Zhou, W., Zhao, X., Lu, X., Liu, L., Wu, Z., Cheng, P., Zhao, W., Huang, C.: The 3Mv multi-element AMS in Xi’an, China: unique features and preliminary tests. Radiocarbon 48, 285–293 (2006)

Middleton, R., Klein, J., Fink, D.: A CO2 negative ion source for 14C dating. Nucl. Instrum. Methods Phys. Res., Sect. B 43, 231–239 (1989)

Sie, S.H., Sims, D.A., Niklaus, T.R., Suter, G.F.: A fast bouncing system for the high-energy end of AMS. Nucl. Instrum. Methods Phys. Res., Sect. B 172, 268–273 (2000)

Jacob, S.A.W., Suter, M., Synal, H.A.: Ion beam interaction with stripper gas—key for AMS at sub-MeV. Nucl. Instrum. Methods Phys. Res., Sect. B 172, 235–241 (2000)

Nadeau, M.J., Lee, H.W., Litherland, A.E., Purser, K.H., Zhao, X.L.: E/Q and ME/Q2 interference in the two models of 14C tandetron systems: towards the 21st century. Nucl. Instrum. Methods Phys. Res., Sect. B 223/224, 328–332 (2004)

Simon, K.J., Pedro, J.B., Smith, A.M., Child, D.P., Fink, D.: Reprocessing of 10Be-contaminated 10Be AMS targets. Nucl. Instrum. Methods Phys. Res., Sect. B 294, 208–213 (2013)

Smith, A.M., Hua, Q., Williams, A., Levchenko, V., Yang, B.: Development in micro-sample 14C AMS at ANTARES AMS facility. Nucl. Instrum. Methods Phys. Res., Sect. B 268, 919–923 (2010)

Biddulph, D.L., Beck, J.W., Burr, G.S., Donahue, D.J., Hatheway, A.L., Jull, A.J.T.: Measurement of the radioisotope I-129 at the NSF-Arizona AMS laboratory. Nucl. Instrum. Methods Phys. Res., Sect. B 172, 693–698 (2000)

Nimz, G.J., Brown, T.A., Tumey, S.J., Marchetti, A.A., Vu, A.K.: Iodine-129 AMS for earth science, biological and national security application, UCRL-TRUCRL-TR-228252. Lawrence Livermore National Laboratory (2007)

Bazán, J.C., De Ferreira, M.E.G.: The reaction between Al and AgI. Corros. Sci. 20, 1129–1138 (1980)

Acknowledgments

The authors acknowledge financial support for this work through the projects of National Science Foundation of China (no. 11405176 and no. 41271512) and the project of Innovation Methodology (no. 2012IM030200) from the Ministry of Science and Technology of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Q., Hou, X., Zhou, W. et al. Accelerator Mass Spectrometry Analysis of Ultra-Low-Level 129I in Carrier-Free AgI-AgCl Sputter Targets. J. Am. Soc. Mass Spectrom. 26, 725–733 (2015). https://doi.org/10.1007/s13361-015-1086-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13361-015-1086-1