Abstract

Ni2P/SBA-15 precursors with Ni2P loadings of 25 wt% and initial P/Ni of 0.8 were prepared using nickel nitride as nickel source, diammonium hydrogen phosphide as phosphorus and mesopore molecular sieve SBA-15 as support. Then Ce was introduced into the Ni2P/SBA-15 precursor. The novel mesoporous Ce-Ni2P/SBA-15 catalysts were prepared after temperature-programmed reduction in flowing H2. The structure was characterized by X-ray diffraction, N2 adsorption–desorption isotherms, NH3 temperature-programmed desorption and X-ray photoelectron spectroscopy. The catalytic activities for the hydrodesulfurization (HDS) of dibenzothiophene (DBT) were evaluated. The results showed that only Ni2P phase was formed in Ce-Ni2P/SAB-15 catalysts with Ce loadings of 0–5 wt%. Ni2P and Ni12P5 phases were existed in 7 wt% Ce-Ni2P/SBA-15 catalyst. The surface area and pore volume increased when Ce was added to Ni2P/SBA-15 catalyst. The strength of the acid sites and total acid amount of Ce-Ni2P/SBA-15 catalysts increased with increasing Ce loadings. Ce existed in the form of Ce3+and Ce4+, Ni existed in the form of Ni2+ and Niδ+, and P existed in the form of Pδ− and P5+. The addition of Ce to the Ni2P/SBA-15 catalyst decreased Niδ+ concentration in Ni2P/SBA-15 catalyst. The activity for HDS of DBT over Ni2P/SBA-15 catalysts was affected by the addition of Ce at 300–340 °C. The catalysts exhibited a good catalytic performance of deep hydrodesulfurization of dibenzothiophene and the conversion of DBT can reach 98.9 % at 380 °C. Biphenyl was the main product over Ce-Ni2P/SBA-15 catalysts and cyclohexylbenzene was the main product over Ni2P/SBA-15 catalyst at 380 °C.

Similar content being viewed by others

Introduction

Automobile industrial developments in the worldwide have increased the environmental pollution. Thus, the stricter standard for gasoline and diesel had been implemented, including decreased S content limits [1, 2]. Alumina-supported Mo or W sulfides by Ni or Co are mostly used as commercial hydrodesulfurization (HDS) catalysts on which dibenzothiophene (DBT) and 4,6-dimethyldibenzothiophene (4,6-DMDBT) are very difficult to remove [3]. So the novel high performance HDS catalysts are urgent to develop under the stringent legislation.

In the recent research, transition phosphides has been attracting attention as the next generation catalysts in the field of HDS, such as hydrogenation [4], hydrazine decomposition [5], especially hydrodesulfurization and hydrodenitrogenation [6, 7], due to their unique physical and chemical properties. Oyama et al. [8] reported that the activity of DBT HDS over Ni2P/SiO2 was higher than commercial Co–Mo sulfide catalysts. Mesopore molecular sieve belongs to regular channel structure that can promote large molecular diffusion in hydrocracking reaction. Wang et al. [9] had reported that the surface area and pore diameter of Ni2P/MCM-41 were larger than that of Ni2P/SiO2 and Ni2P/Al2O3 catalysts. It was also reported by Oyama that the catalytic performance for HDS of 4,6-DMDBT over Ni2P/MCM-41 catalyst was higher than that of Ni2P/SiO2 catalyst [10]. Our previous work reported that Ni2P/SBA-15 catalysts exhibited excellent deep activity of DBT HDS [11].

Hydrodesulfurization performance could be tunable by adding promoter to Ni2P catalyst. Abu et al. [12] reported that the addition of Co to Ni2P bulk catalyst brought an increase in 4,6-DMDBT HDS activity and selectivity. In previous paper [13], our group had reported the catalytic activity of Mo-Ni2P/SBA-15/cordierite catalysts for DBT HDS, the addition of Mo to Ni2P/SBA-15/Cordierite can promote the DBT activity and selectivity and the mechanism over Mo-Ni2P/SBA-15/cordierite can be changed at 380 °C. It has been shown that cerium promoter could improve catalytic performance in some catalytic reactions. Li et al. [14] demonstrated that the influence of CeO2 on hydrogenation activity over bulk Ni2P. CeO2 was an effective promoter enhancing the hydrogenation activity of 1-heptene and toluene over Ni2P catalyst. Besides, Li et al. [15] also found that CeO2 promoters could improve the activity of quinoline hydrodenitrogenation (HDN) over Ni2P. Cai et al. [16] reported the effect of promoter Ce on the catalytic performance of Ni/Al2O3 catalyst for autothermal reforming of methane to hydrogen. The result showed that the addition of Ce to the Ni/Al2O3 catalyst increased the active surface that promoted the activity of the catalyst. In this study, the effect of Ce on DBT HDS over Ni2P/SBA-15 catalyst is investigated. The relationship between the structures and catalytic activities of the catalysts are discussed.

Experimental

Preparation of catalyst

SBA-15 was synthesized using the literature method [17]. Ni2P/SBA-15 precursors with P/Ni molar ratio of 0.8 were prepared by impregnating an aqueous solution of (NH4)2HPO4 and Ni(NO3)2·6H2O (add little HNO3 if precipitation was formed) into SBA-15 for 12 h. Then dried at 120 °C for 24 h and subsequently calcined the sample at 550 °C for 4 h. The content of Ni2P was about 25 wt%. Prior to H2-TPR, the precursor was crushed to 40–60 mesh. 100 mL/min H2 flow was used to reduce the precursor by heating from room temperature (RT) to 300 °C at 10 °C min−1, then from 300 to 650 °C at 1 °C min−1, and finally maintained at 650 °C for 2 h. After the reduction, the catalysts were cooled to RT and passivated by 1 % O2/Ar (v/v) for structure characterization, or for HDS of DBT. Based on the above sample, Ce-Ni2P/SBA-15 samples were prepared by impregnating aqueous solutions of Ce(NO3)3·6H2O with different concentration into the above Ni2P/SBA-15 precursors at RT for 12 h, followed by drying the sample at 120 °C for 24 h and eventually calcining the sample at 550 °C for 4 h. The contents of Ce were 0–7 wt%.

Catalyst characterization

X-ray diffraction (XRD) patterns of Ce-Ni2P/SBA-15 catalysts were obtained on a Rigaku D/Max 2500 VB2 +/PC diffractometer using Cu Kα radiation operating at 200 mA and 40 kV. N2 adsorption–desorption isotherms of Ce-Ni2P/SBA-15 catalysts were measured using a Quadrasorb SI instrument. Before measurement, the sample was outgassed for at least 5 h at 350 °C under vacuum. BET and BJH methods were used to determine the specific surface area and pore size distribution, respectively. NH3-TPD data were collected from Thermo Electron TPD/R/O 1100 series catalytic surfaces analyzer equipped with a TC detector. Each sample was initially pretreated through heating in 20 ml/min of nitrogen from ambient to 300 °C, with a 1 h hold. The sample was then cooled down to ambient; ammonia adsorption was carried out. Physically adsorbed ammonia was removed by purging with nitrogen at 100 °C for 1 h. NH3-TPD of the sample was carried out by increasing the temperature linearly from 40 to 800 °C with a heating rate of 10 K/min and a helium flow rate of 20 ml/min. XPS experiments were carried out on an ESCALAB 250 (Thermo Electron Co.) instrument using Al Kα as the exciting radiation at constant pass energy of 30 eV. Binding energies were calibrated using the carbon present as a contaminant (C 1s = 285.0 eV).

Catalytic activity testing

The HDS of DBT was performed in a high-pressure fixed-bed continuous-flow stainless steel reactor (9 mm in diameter and 500 mm in length) with a central thermocouple to measure the temperature of the catalyst bed. Ce-Ni2P/SBA-15 catalyst with different Ce loadings was loaded on the fixed-bed reactor between the pads of quartz sand. The reaction feed consisting of 1 wt% DBT in decalin was introduced into the reactor by a piston pump. The HDS reaction was operated at 3.0 MPa from 300 to 380 °C, liquid hourly space velocity = 1.9 h−1, and the ratio of hydrogen-to-liquid feed was 400 (v/v). The liquid products were collected at 1 h intervals and analyzed by an off-line gas chromatography [SP2100, Beijing Beifenruili Analytic Instrument (Group) Co., Ltd], equipped with a flame ionization detector and a capillary column (HJ. PONA, 50 m × 0.20 mm × 0.50 μm).

Results and discussion

XRD of Ce-Ni2P/SBA-15 catalysts

Figure 1 shows the XRD patterns of Ce-Ni2P/SBA-15 catalysts with different Ce loadings. In the case of Ni2P/SBA-15 catalyst, the diffraction peak of the Ni2P phase located at 2θ = 40.6°, 44.5°, 47.3° and 54.1° (PDF-03-0953) had been observed, suggesting that Ni2P was formed in the Ni2P/SBA-15 catalyst. None of new diffraction peak appeared in the XRD patterns of Ce-Ni2P/SBA-15 catalysts with Ce ≤ 5 wt%. For 7 % Ce-Ni2P/SBA-15 catalyst, the diffraction peak of the Ni12P5 phase appeared, which was located at 2θ = 38.4º, 41.6º and 48.9º (PDF-22-1190). This indicated that Ni2P and Ni12P5 phases existed in 7 % Ce-Ni2P/SBA-15.

The diffraction peak of Ce species was not shown with the increasing of Ce loadings in Ce-Ni2P/SBA-15 catalysts, indicating that Ce was well dispersed in SBA-15 or Ce concentration was too low. The result agreed with the literature [14]. Besides, No cerium phosphides (Ce2Ni12P7 and CeNi2P2), cerium nickel phosphide (Ce6Ni6P17) or cerium oxide species were observed when Ce was added to Ni2P bulk catalyst. In the literature [18], the formation of Ni12P5 was attributed to the loss of phosphorus in temperature-programmed reduction process. It has reported by Abu et al. [12] that Ni12P5 and Ni2P phases were formed due to the addition of excess Co to Ni2P bulk catalyst. Therefore, it was thought that the addition of excess Ce to Ni2P/SBA-15 catalyst inhibited enough phosphorus contacted with nickel to form Ni2P phase. So in 7 % Ce-Ni2P/SBA-15 catalyst, Ni12P5 phase was formed. Furthermore, the intensity of Ni2P diffraction peaks was slightly decreased with the increasing of Ce. This also corresponded to the previous research [19].

N2 adsorption–desorption of Ce-Ni2P/SBA-15 catalysts

N2 adsorption–desorption isotherms of Ni2P/SBA-15 and Ce-Ni2P/SBA-15 catalysts are shown Fig. 2. It can be observed that the nitrogen adsorption–desorption isotherms of all catalysts were found to be of type IV according to IUPAC classification. All catalysts exhibited a H1 hysteresis loop that was a typical mesoporous solid [17]. This indicated that all catalysts retained SBA-15 mesoporous structure.

The pore structure parameters are summarized in Table 1. For Ni2P/SBA-15 catalyst, the values of the SBET, Vp and DBJH were 247.8 m2/g, 0.30 m3/g and 3.8 nm, respectively. In the case of Ce-Ni2P/SBA-15 catalysts, the values of SBET and Vp were higher than that of Ni2P/SBA-15 catalyst. It suggested that favorable influence on SBET and Vp was shown by adding cerium in Ni2P/SBA-15 catalyst. Abu et al. [12] recognized that the increased BET surface area of CoxNi2P and Co0.08MoP suggested a reduction in the degree of agglomeration of the larger crystallites when the Co was added. Compared with 5 % Ce-Ni2P/SBA-15 catalyst, the values of SBET and Vp of 7 % Ce-Ni2P/SBA-15 catalyst slightly decreased. This could be attributed to the dispersibility of active component which was weakened by adding the excess amount of cerium. However, the values of DBJH were similar to that of Ni2P/SBA-15 catalyst, which indicated that Ce-Ni2P existed in the SBA-15 pore channel. Gutierrez et al. [20] recognized that desorption pore diameter of NiMo/Zr-SBA-15 catalysts was related with metal contents. The pore diameter was stable due to the metal existed in the Zr-SBA-15 channel when metal loadings were low, and the pore diameter decreases because high metal loadings blocked the SBA-15 pore mouth.

NH3-TPD of Ce-Ni2P/SBA-15 catalysts

Hydrodesulfurization activity and selectivity were related to acidity according to some investigates. In this work, the acidity of the Ce-Ni2P/SBA-15 catalysts was investigated by temperature-programmed desorption of ammonia (NH3-TPD). The technique provided information on the total acidity of the solid and strength of acid sites.

The NH3-TPD profiles of Ce-Ni2P/SBA-15 catalysts with different Ce loadings are presented in Fig. 3. It can be observed two desorption peaks on all NH3-TPD curves. One was the large peak at lower temperature assigned to weak acid sites. The other was small peak at higher temperature assigned to strong acid site.

Generally, the acid sites were classified into the weak (≤200 °C), medium (200–350 °C) and strong (≥350 °C) acid sites [21]. With regard to Ni2P/SBA-15 catalyst, there were two peaks: the large desorption peak with the start desorption temperature at 145 °C and maximum desorption temperature at 216 °C, and the small desorption peak with the start desorption temperature at 540 °C and the maximum desorption temperature at 575 °C. Hu et al. [22] reported the desorption temperature at 114 °C of SBA-15 associated with Si–OH bond. Duan et al. [23] recognized that the metal atom in metal phosphide transferred into phosphorus atom resulting in the formation of acid site (252 and 620 °C). In the case of Ce-Ni2P/SBA-15 catalysts, the start desorption temperature and the maximum desorption temperature are shifted to higher temperature with the increasing of Ce loadings. This suggested that the strength of acid sites of Ce-Ni2P/SBA-15 catalysts was higher than that of Ni2P/SBA-15 catalyst. Kalita et al. [24] reported that the strength of acid was related to desorption temperature. With the increasing of the desorption temperature, the strength of acid increased.

The total acid amount values are given in the Table 2. The value of Ni2P/SBA-15 catalyst was 869 μmol/g, and the values of Ce-Ni2P/SBA-15 catalysts increased with increasing Ce, which showed that Ce could improve the acid amount of Ni2P/SBA15 catalyst. Yu et al. [25] reported that the Ce addition to the Pt–Sn/γ-Al2O3 catalyst can increase acid amount of Pt–Sn/γ-Al2O3 catalyst.

XPS of Ce-Ni2P/SBA-15 catalysts

XPS spectra of Ce-Ni2P/SBA-15 catalysts were shown in Fig. 4. As seen in the Fig. 4a are Ce3d5 spectra of Ce-Ni2P/SBA-15 catalysts. The two binding energy (BE) peaks at 882.2 and 884.6 eV are assigned to Ce4+ and Ce3+ species [26]. Holgado et al. [27] reported that Ar+ bombardment of CeO2 produces a complete reduction to Ce2O3 by preferential removal of oxygen from the altered zone in the XPS measurement process. Sun et al. [28] demonstrated that the banding energy exhibited at ~882 and ~886 eV could be ascribed to CeO2 and Ce2O3. In this literature, the XPS results of Ce3d5 spectra for Ce-Ni2P/SBA-15 catalysts were consistent well with the publications.

Ni2p3 spectra of Ce-Ni2P/SBA-15 catalysts are present in Fig. 4b. For Ni2P/SBA-15 catalyst, the Ni2p3 BE peaks were at 853.5 and 857.2 eV, respectively. This could be assigned to Niδ+(0 < δ < 2)and Ni2+. With regard to Ce-Ni2P/SBA-15 catalysts, the Ni2p3 BE peaks were almost unaffected by the addition of Ce, suggesting that the addition of Ce did not affect the electronic properties of Ni2P/SBA-15 catalyst. This was probably due to the Ce species introduced by the impregnation method which were mainly located on the surface of the catalysts. It was reported by Burns et al. [29] that the Ni 2p3/2 binding energy at 853.7 and 857.3 eV was assigned to Niδ+ species and Ni2+ species. Ni2+ species was formed in Ce-Ni2P/SBA-15 catalysts because the samples were passivated with 1 % O2 in Ar before XPS measurement.

Figure 4c shows the P2p3 spectra of Ce-Ni2P/SBA-15 catalysts. In the case of Ni2P/SBA-15 catalyst, the P2p3 BE peaks located at 129.5 eV could be attributed to Pδ− species, and could be related to Ni2P. The BE peaks located at 133.3 and 134.6 eV could be attributed to P5+ species, which could be related to phosphate ions and phosphorus pentoxide. For Ce-Ni2P/SBA-15 catalysts, the value of the BE peaks was also located at the same position. It meant that the addition of Ce in Ni2P/SBA-15 catalyst did not affect the valence of P. It had been reported that the formation of phosphorus pentoxide is mainly due to the superficial oxidation of nickel phosphide after the passivation by 1 % O2/Ar (v/v) [29].

The surface atom concentration and the binding energy are shown in Table 3. As seen in the Table 3, the Ce surface atom concentration increased with the increasing of Ce loadings. Niδ+ atom relative concentration evidently decreased with the increasing of Ce loadings. P atom relative concentration slightly shifted to the low value, indicating that the amount of active sites decreased when Ce was added to Ni2P/SBA-15 catalyst. Oyama et al. had been reported that Niδ+ in Ni2P was the active site for HDS of 4,6-DMDBT [10]. So the decreasing of Niδ+ species reduced the activity of DBT HDS over Ce-Ni2P/SBA-15 catalysts.

Catalytic activity of Ce-Ni2P/SBA-15 catalysts

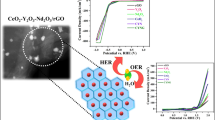

The catalytic performance of Ce-Ni2P/SBA-15 catalysts with different Ce loadings for HDS of DBT is presented in the Fig. 5a. The conversion of DBT was 40.8 % at 300 °C and 98.9 % at 380 °C over Ni2P/SBA-15 catalyst. Compared with Ni2P/SBA-15 catalyst, Ce-Ni2P/SBA-15 catalysts had lower DBT conversion at 300–340 °C, and DBT conversion decreased with the increasing of Ce loadings. This was attributed to the relative concentration of Niδ+ was decreased when Ce was added to Ni2P/SBA-15 catalyst. In other words, the contact of the reactants and the Ni2P active site may be restrained by adding Ce to Ni2P/SBA-15 catalyst. 7 % Ce-Ni2P/SBA-15 catalyst had the lowest DBT conversion at lower temperature, which can reach 29.9 % at 300 °C and 77.5 % at 340 °C.

It can be proposed that not only the low Ni2P active sites but also the formation of Ni12P5 resulted in lowest activity over 7 % Ce-Ni2P/SBA-15 catalyst. Korányi et al. [30] reported that Ni12P5 gave a lower active when compared with Ni2P for HDS of DBT. At 360–380 °C, Ni2P/SBA-15 and Ce-Ni2P/SBA-15 catalysts exhibited similar HDS conversion. Chen et al. [31] reported that the apparent reaction rate constant increased with increasing the temperature. Higher DBT conversion was shown over Ni2P/SBA-15 catalyst than that over Ce-Ni2P/SBA-15 catalyst at 300–340 °C, mainly due to more active sites in Ni2P/SBA-15 catalyst. DBT HDS reaction had high apparent reaction rate constant at 360–380 °C. So Ce-Ni2P/SBA-15 catalyst with fewer active sites exhibited similar DBT conversion with Ni2P/SBA-15 catalyst.

Furthermore, –OH on the surface of SBA-15 could connect Ce and form Si–O–Ce bond [32, 33], and this bond may block the mouth of the mesopore. This meant that less contents of DBT could come into the pore of Ce-Ni2P/SBA-15 catalysts, and this could decrease the conversion of DBT. From the data of pore structure parameters and previous reference [20], we could also get this point. Then the contents of Ce reached 7 %. Some of Ce was incorporated into SBA-15 and led to the decrease of surface areas. Then the conversion of DBT could be reduced due to the decreased surface areas. This was also consistent with our previous research [34].

The Fig. 5b shows the selectivity of BP and CHB over Ce-Ni2P/SBA-15 catalysts with different Ce loadings. BP and CHB selectivity over Ni2P/SBA-15 catalyst was changed slightly at 300–340 °C, and BP selectivity decreased apparently at 360–380 °C. Compared with Ni2P/SBA-15, BP and CHB selectivity over Ce-Ni2P/SBA-15 was similar at 300–340 °C, respectively. However, BP selectivity was apparently lower than that of Ce-Ni2P/SBA-15 at 360–380 °C. So the addition of Ce to Ni2P/SBA-15 catalyst could regulate the selectivity of BP and CHB at 360–380 °C. Generally, BP, CHB and traces amount of H4-DBT (can be neglected) are the products of DBT HDS. The mechanism of DBT HDS could occur through two parallel reactions (seen in scheme 1), direct desulfurization (DDS) and desulfurization after hydrogenation (HYD). For DDS route, the main product is BP. For HYD route, H4-DBT is first developed and then quickly converted to CHB [35]. Abu et al. [12] reported that the 4,6-DMDBT selectivity can be enhanced by adding Co species to Ni2P due to the increased acidity. In this paper, the addition of Ce to Ni2P/SBA-15 catalyst improved the strength of acid site and the amount of acid. BP selectivity over Ce-Ni2P/SBA-15 catalyst was higher than that of Ni2P/SBA-15 catalyst especially at 360–380 °C, indicating that increased acid properties could enhance BP selectivity over Ce-Ni2P/SBA-15 catalysts. On the contrary, CHB selectivity was decreased during this period. In other words, the enhanced BP selectivity followed DDS route over Ce-Ni2P/SBA-15 catalyst when compared with Ni2P/SBA-15 catalyst.

Conclusions

A series of Ce-Ni2P/SBA-15 catalysts with different Ce loadings were prepared by impregnation method. The structure of as-synthesized catalysts and their HDS performance were investigated. Only Ni2P phase existed in Ce-Ni2P/SBA-15 when Ce ≤ 5 wt %, and Ni2P and Ni12P5 phases existed in 7 % Ce-Ni2P/SBA-15 catalyst. The surface area and pore volume were increased when Ce was added to Ni2P/SBA-15 catalyst. The strength of acid site and the amount of acid over Ce-Ni2P/SBA-15 catalyst was higher than that over Ni2P/SBA-15 catalyst. The amount of active sites in Ni2P/SBA-15 was higher than that of Ce-Ni2P/SBA-15 catalyst. Compared with Ni2P/SBA-15 catalyst, the Ce-Ni2P/SBA-15 catalysts gave lower HDS of DBT performance at 300–340 °C. However, similar catalytic activity was showed over these catalysts for HDS of DBT at 360–380 °C. The addition of Ce to Ni2P/SBA-15 catalyst apparently enhanced BP selectivity at 360–380 °C.

References

Song CS (2003) An overview of new approaches to deep desulfurization for ultra-clean gasoline, diesel fuel and jet fuel. Catal Today 86:211–263

Stanislaus A, Marafi A, Rana MS (2010) Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production. Catal Today 153:1–68

Varakin AN, Nikul’shin PA, Pimerzin AA, Sal’nikov VA, Pimerzin AA (2013) Hydrogen spillover effect in the presence of CoSx/Al2O3 and bulk MoS2 in hydrodesulfurization, hydrodenitrogenation and hydrodeoxygenation. Russian J Appl Chem 86:718–726

Li X, Bai J, Wang A, Prins R, Wang Y (2011) Hydrodesulfurization of dibenzothiophene and its hydrogenated intermediates over bulk Ni2P. Top Catal 54:290–298

Ding L, Shu Y, Wang A, Zheng M, Li L, Wang X, Zhang T (2010) Preparation and catalytic performances of ternary phosphides NiCoP for hydrazine decomposition. Appl Catal A Gen 385:232–237

Sal’nikov VA, Nikul’shin PA, Pimerzin (2013) The catalytic properties of transition metal sulfides synthesized from Anderson-type heteropoly compounds in hydrogenation, hydrodesulfurization, and hydrodenitrogenation reactions. Pet Chem 53:233–244

Biswas P, Narayanasarma P, Kotikalapudi CM, Dalai AK, Adjaye J (2011) Characterization and activity of ZrO2 doped SBA-15 supported MiMo catalysts for HDS and HDN of bitumen derived heavy gas oil. Ind Eng Chem Res 50:7882–7895

Oyama ST (2003) Novel catalysts for advanced hydroprocessing: transition metal phosphides. J Catal 216:343–352

Wang AJ, Ruan LF, Teng Y, Li X, Lu MH, Ren J, Wang Y, Hu YK (2005) Hydrodesulfurization of dibenzothiophene over siliceous MCM-41-supported nickel phosphide catalysts. J Catal 229:314–321

Oyama ST, Lee YK (2008) The active site of nickel phosphide catalysts for the hydrodesulfurization of 4,6-DMDBT. J Catal 258:393–400

Huang X, Ji S, Wu P, Liu Q, Liu H, Zhu J, Li C (2008) Structure and hydrodesulfurization performances of Ni2P/SBA-15 catalysts. Acta Phys Chim Sin 24:1773–1778

Abu II, Smith KJ (2006) The effect of cobalt addition to bulk MoP and Ni2P catalysts for the hydrodesulfurization of 4,6-dimethyldibenzothiophene. J Catal 241:356–366

Guo Y, Zeng P, Ji S, Wei N, Liu H, Li C (2010) Effect of Mo promoter content on performance of Mo-Ni2P/SBA-15/cordierite monolithic catalyst for hydrodesulfurization. Chin J Catal 31:329–334

Li X, Zhang YL, Wang AJ, Wang Y, Hu YK (2010) Influence of TiO2 and CeO2 on the hydrogenation activity of bulk Ni2P. Catal Commun 11:1129–1132

Li X, Sun Z, Wang A, Wang Y (2010) Hydrodenitrogenation performance of TiO2- and CeO2-promoted Ni2P catalysts. Prepr Pap Am Chem Soc Div Fuel Chem 55(1):205–206

Cai X, Dong X, Lin W (2008) Effect of CeO2 on the catalytic performance of Ni/Al2O3 for autothermal reforming of methane. J Nat Gas Chem 17:9–102

Zhao D, Sun J, Li Q, Stucky GD (2000) Morphological control of highly ordered mesoporous silica SBA-15. Chem Mater 12:275–279

Oyama ST, Wang X, Lee YK, Bando K, Requejo FG (2002) Effect of phosphorus content in nickel phosphide catalysts studied by XAFS and other techniques. J Catal 210:207–217

Chen C, Liao H, Guo G, Shi Q, Chen W, Zhang R (2012) Influence of hydrodesulfurization of thiophene over Ni2P catalysts supported on the Ce-activated bentonite. Nonmet Mines 35(4):1–3

Gutiérrez OY, Fuentes GA, Salcedo C, Klimova T (2006) SBA-15 supports modified by Ti and Zr grafting for NiMo hydrodesulfurization catalysts. Catal Today 116:485–497

Sundaramurthy V, Eswaramoorthi I, Dalai AK, Adjaye J (2008) Hydrotreating of gas oil on SBA-15 supported NiMo catalysts. Microporous Mesoporous Mater 111:560–568

Hu L, Ji S, Liu Q, Wu P, Zhu J, Li C (2007) Surface acidity and hydroxyl groups of SBA-15 mesoporous silica catalysts containing tungsten species. Chin J Catal 28:980–986

Duan X, Teng T, Wang A, Kogan VM, Li X, Wang Y (2009) Role of sulfur in hydrotreating catalysis over nickel phosphide. J Catal 261:232–240

Kalita P, Gupta NM, Kumar R (2007) Synergistic role of acid sites in the Ce-enhanced activity of mesoporous Ce-Al-MCM-41 catalysts in alkylation reactions: FTIR and TPD-ammonia studies. J Catal 245:338–347

Yu C, Ge Q, Xu H, Li W (2006) Effects of Ce addition on the Pt–Sn/γ-Al2O3 catalyst for propane dehydrogenation to propylene. Appl Catal A Gen 315:58–67

Padilla JM, Angel GD, Navarrete J (2008) Improved Pd/γ-Al2O3–Ce catalysts for benzene combustion. Catal Today 133–135:541–547

Holgado JP, Munuera G, Espinos JP, Gonzalez-Elipe AR (2000) XPS study of oxidation processes of CeO defective layers. Appl Surf Sci 158:164–171

Sun Z, Li X, Wang A, Wang Y, Chen Y (2012) The effect of CeO2 on the hydrodenitrogenation performance of bulk Ni2P. Top Catal 55:1010–1021

Burns AW, Gaudette AF, Bussell ME (2008) Hydrodesulfurization properties of cobalt–nickel phosphide catalysts: Ni-rich materials are highly active. J Catal 260:262–269

Korányi TI, Vít Z, Poduval DG, Ryoo R, Kim HS, Hensen EJM (2008) SBA-15-supported nickel phosphide hydrotreating catalysts. J Catal 253:119–131

Chen J, Yang H, Ring Z (2004) HDS kinetics study of dibenzothiophenic compounds in LCO. Catal Today 98:227–233

Subbaramaiah V, Srivastava VC, Mall ID (2013) Catalytic wet peroxidation of pyridine bearing wastewater by cerium supported SBA-15. J Hazard Mater 248–249:355–363

Levasseur B, Ebrahim AM, Burress J, Bandosz TJ (2011) Interactions of NO2 at ambient temperature with cerium–zirconium mixed oxides supported on SBA-15. J Hazard Mater 197:294–303

Wei N, Ji SF, Wu PY, Guo YN, Liu H, Zhu JQ, Li CY (2009) Preparation of nickel phosphide/SBA-15/cordierite monolithic catalysts and catalytic activity for hydrodesulfurization of dibenzothiophene. Catal Today 1475:S66–S70

Chen T, Wang CM, Wang I, Tsai TC (2010) Promoter effect of vanadia on Co/Mo/Al2O3 catalyst for deep hydrodesulfurization via the hydrogenation reaction pathway. J Catal 272:28–36

Acknowledgments

The authors thank for the financial support of the National Natural Science Foundation of China (Grants 20473009) and the National Basic Research Program of China (973 Project No. 2006CB202503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Li, Q., Wu, P., Lan, L. et al. Preparation of novel mesoporous Ce-Ni2P/SBA-15 catalysts and their catalytic performance for hydrodesulfurization of dibenzothiophene. Appl Petrochem Res 4, 209–216 (2014). https://doi.org/10.1007/s13203-013-0039-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-013-0039-5