Abstract

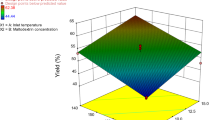

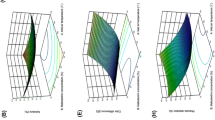

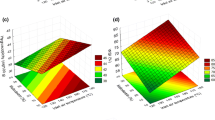

In this study, the effects of main spray drying conditions such as inlet air temperature (100–140 °C), maltodextrin concentration (MDC: 30–60%), and aspiration rate (AR) (30–50%) on the physicochemical properties of sour cherry powder such as moisture content (MC), hygroscopicity, water solubility index (WSI), and bulk density were investigated. This investigation was carried out by employing response surface methodology and the process conditions were optimized by using this technique. The MC of the powder was negatively related to the linear effect of the MDC and inlet air temperature (IT) and directly related to the AR. Hygroscopicity of the powder was significantly influenced by the MDC. By increasing MDC in the juice, the hygroscopicity of the powder was decreased. MDC and inlet temperature had a positive effect, but the AR had a negative effect on the WSI of powder. MDC and inlet temperature negatively affected the bulk density of powder. By increasing these two variables, the bulk density of powder was decreased. The optimization procedure revealed that the following conditions resulted in a powder with the maximum solubility and minimum hygroscopicity: MDC = 60%, IT = 134 °C, and AR = 30% with a desirability of 0.875.

Similar content being viewed by others

References

Adhikari B, Howes T, Bhandari B, Langrish T (2009a) Effect of addition of proteins on the production of amorphous sucrose powder through spray drying. J Food Eng 94:144–153

Adhikari B, Howes T, Wood B, Bhandari B (2009b) The effect of low molecular weight surfactants and proteins on surface stickiness of sucrose during powder formation through spray drying. J Food Eng 94:135–143

Anderson R, Conway H, Pfeifer V, Griffin E (1969) Gelatinization of corn grits by roll-and extrusion-cooking. Cereal Sci Today 14:4

Baldwin A, Truong G (2007) Development of insolubility in dehydration of dairy milk powders. Food Bioprod Process 85:202–208

Bhandari B, Bansal N, Zhang M, Schuck P (2013) Handbook of food powders: processes and properties. Elsevier, Amsterdam

Bobe G, Wang B, Seeram NP, Nair MG, Bourquin LD (2006) Dietary anthocyanin-rich tart cherry extract inhibits intestinal tumorigenesis in APCMin mice fed suboptimal levels of sulindac. J Agric Food Chem 54:9322–9328

Cai Y, Corke H (2000) Production and properties of spray-dried Amaranthus betacyanin pigments. J Food Sci Chicago 65:1248–1252

Caliskan G, Dirim SN (2013) The effects of the different drying conditions and the amounts of maltodextrin addition during spray drying of sumac extract. Food Bioprod Process 91:539–548

Cano-Chauca M, Stringheta P, Ramos A, Cal-Vidal J (2005) Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov Food Sci Emerg Technol 6:420–428

Chegini G, Ghobadian B (2005) Effect of spray-drying conditions on physical properties of orange juice powder. Drying Technol 23:657–668

Dodds J, Bhandari B, Bansal N, Zhang M, Schuck P (2013) Techniques to analyse particle size of food powders. Handbook of food powders: processes and properties 309–338

Ferrari CC, Germer SPM, de Aguirre JM (2012) Effects of spray-drying conditions on the physicochemical properties of blackberry powder. Drying Technol 30:154–163

Goula AM, Adamopoulos KG (2005) Spray drying of tomato pulp in dehumidified air: II. The effect on powder properties. J Food Eng 66:35–42

Goula AM, Adamopoulos KG (2010) A new technique for spray drying orange juice concentrate. Innov Food Sci Emerg Technol 11:342–351

Goula AM, Adamopoulos KG, Kazakis NA (2004) Influence of spray drying conditions on tomato powder properties. Drying Technol 22:1129–1151

Jayasundera M, Adhikari B, Adhikari R, Aldred P (2011) The effect of protein types and low molecular weight surfactants on spray drying of sugar-rich foods. Food Hydrocolloids 25:459–469

Jumah R, Tashtoush B, Shaker R, Zraiy A (2000) Manufacturing parameters and quality characteristics of spray dried jameed. Drying Technol 18:967–984

Kang S-Y, Seeram NP, Nair MG, Bourquin LD (2003) Tart cherry anthocyanins inhibit tumor development in Apc Min mice and reduce proliferation of human colon cancer cells. Cancer Lett 194:13–19

Lachin T, Reza H (2012) Anti diabetic effect of cherries in alloxan induced diabetic rats. Recent Pat Endocr Metab Immune drug Discov 6:67–72

Mishra P, Mishra S, Mahanta CL (2014) Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod Process 92:252–258

Muzaffar K, Kumar P (2015) Parameter optimization for spray drying of tamarind pulp using response surface methodology. Powder Technol 279:179–184

Santhalakshmy S, Bosco SJD, Francis S, Sabeena M (2015) Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol 274:37–43

Tonon RV, Brabet C, Hubinger MD (2008) Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J Food Eng 88:411–418

Tuyen CK, Nguyen MH, Roach PD (2010) Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J Food Eng 98:385–392

Walton D (2000) The morphology of spray-dried particles a qualitative view. Drying Technol 18:1943–1986

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moghaddam, A.D., Pero, M. & Askari, G.R. Optimizing spray drying conditions of sour cherry juice based on physicochemical properties, using response surface methodology (RSM). J Food Sci Technol 54, 174–184 (2017). https://doi.org/10.1007/s13197-016-2449-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2449-8