Abstract

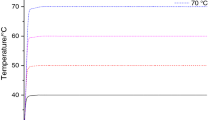

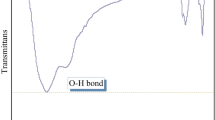

This work studied the drying kinetics of the organic fractions of municipal solid waste (MSW) samples with different initial moisture contents and presented a new method for determination of drying kinetic parameters. A series of drying experiments at different temperatures were performed by using a thermogravimetric technique. Based on the modified Page drying model and the general pattern search method, a new drying kinetic method was developed using multiple isothermal drying curves simultaneously. The new method fitted the experimental data more accurately than the traditional method. Drying kinetic behaviors under extrapolated conditions were also predicted and validated. The new method indicated that the drying activation energies for the samples with initial moisture contents of 31.1 and 17.2 % on wet basis were 25.97 and 24.73 kJ mol−1. These results are useful for drying process simulation and industrial dryer design. This new method can be also applied to determine the drying parameters of other materials with high reliability.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- MR:

-

Moisture ratio

- MSW:

-

Municipal solid waste

- O.F.:

-

Objective function

- RMSE:

-

Root mean square error

- D 0 :

-

Arrhenius preexponential factor

- D eff :

-

Effective moisture diffusivity

- E a :

-

Drying activation energy

- k :

-

Pseudo moisture diffusivity

- k 0 :

-

Pseudo preexponential factor

- L 0 :

-

Half-thickness of the slab

- m :

-

Number of drying temperatures

- n :

-

Exponent

- n d :

-

Number of data points

- R :

-

Universal gas constant

- R2 :

-

Coefficient of determination

- t :

-

Time

- T :

-

Temperature

- w 0 :

-

Initial moisture content

- w e :

-

Equilibrium moisture content

- w t :

-

Moisture content at any particular time

- x :

-

Spatial dimension

- λ :

-

Empirical constant

- cal :

-

Calculated data

- exp :

-

Experimental data

- i :

-

The ith temperature

- j :

-

The jth data point

References

Basso, D., Weiss-Hortala, E., Patuzzi, F., Castello, D., Baratieri, M., Fiori, L.: Hydrothermal carbonization of off-specification compost: a byproduct of the organic municipal solid waste treatment. Bioresour. Technol. 182, 217–224 (2015)

Hoornweg, D., Bhada-Tata, P. What a waste: a global review of solid waste management. World Bank Report: Washington, DC 20433, USA (2012)

Jayasinghe, P.A., Hettiaratchi, J.P.A., Mehrotra, A.K., Kumar, S.: Reaction mechanisms and rate constants of waste degradation in landfill bioreactor systems with enzymatic-enhancement. Bioresour. Technol. 162, 279–282 (2014)

Chandrappa, R., Brown, J.: Solid Waste Management: Principles and Practice. Springer, Berlin (2012)

Chen, D., Yin, L., Wang, H., He, P.: Pyrolysis technologies for municipal solid waste: a review. Waste Manag. 34(12), 2466–2486 (2014)

Yuan, X., Wen, B., Ma, X., Zhu, W., Wang, X., Chen, S., Cui, Z.: Enhancing the anaerobic digestion of lignocellulose of municipal solid waste using a microbial pretreatment method. Bioresour. Technol. 154, 1–9 (2014)

Tawfik, A., El-Qelish, M.: Key factors affecting on bio-hydrogen production from co-digestion of organic fraction of municipal solid waste and kitchen wastewater. Bioresour. Technol. 168, 106–111 (2014)

Pandey, D.S., Pan, I., Das, S., Leahy, J.J., Kwapinski, W.: Multi-gene genetic programming based predictive models for municipal solid waste gasification in a fluidized bed gasifier. Bioresour. Technol. 179, 524–533 (2015)

Yang, Y., Brammer, J.G., Mahmood, A.S.N., Hornung, A.: Intermediate pyrolysis of biomass energy pellets for producing sustainable liquid, gaseous and solid fuels. Bioresour. Technol. 169, 794–799 (2014)

Bridgwater, A.V.: Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 38, 68–94 (2012)

Banks, S.W., Nowakowski, D.J., Bridgwater, A.V.: Fast pyrolysis processing of surfactant washed Miscanthus. Fuel Process. Technol. 128, 94–103 (2014)

Czernik, S., Bridgwater, A.V.: Overview of applications of biomass fast pyrolysis oil. Energy Fuels 18(2), 590–598 (2004)

Perazzini, H., Freire, F.B., Freire, F.B., Freire, J.T.: Thermal treatment of solid wastes using drying technologies: a review. Dry. Technol. (2015). doi:10.1080/07373937.2014.995803

Chen, D., Zhang, Y., Zhu, X.: Drying kinetics of rice straw under isothermal and nonisothermal conditions: a comparative study by thermogravimetric analysis. Energy Fuels 26(7), 4189–4194 (2012)

Jamaleddine, T.J., Ray, M.B.: Application of computational fluid dynamics for simulation of drying processes: a review. Dry. Technol. 28(2), 120–154 (2010)

Kucuk, H., Midilli, A., Kilic, A., Dincer, I.: A review on thin-layer drying-curve equations. Dry. Technol. 32(7), 757–773 (2014)

Chen, D., Zheng, Y., Zhu, X.: In-depth investigation on the pyrolysis kinetics of raw biomass. Part I: kinetic analysis for the drying and devolatilization stages. Bioresour. Technol. 131, 40–46 (2013)

Cai, J., Chen, S.: Determination of drying kinetics for biomass by thermogravimetric analysis under nonisothermal condition. Drying Technol. 26(12), 1464–1468 (2008)

Joardder, M.U., Karim, A., Kumar, C., Brown, R.J.: Determination of effective moisture diffusivity of banana using thermogravimetric analysis. Proc. Eng. 90, 538–543 (2014)

Mujumdar, A.S.: Handbook of Industrial Drying, 3rd edn. CRC Press, Boca Raton (2006)

Erbay, Z., Icier, F.: A review of thin layer drying of foods: theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 50(5), 441–464 (2010)

White, G., Bridges, T., Gewer, O., Ross, I. Seed Coat Devage in Thin Layer Drying of Soybeans as Affected by Drying Conditions. ASAE Paper No. 3052 (1978)

Dadalı, G., Apar, D.K., Özbek, B.: Estimation of effective moisture diffusivity of okra for microwave drying. Dry. Technol. 25(9), 1445–1450 (2007)

Venkataraman, P.: Applied Optimization with MATLAB Programming. Wiley, New York (2009)

Messac, A.: Optimization in Practice with MATLAB. Cambridge University Press, Cambridge (2015)

Demirbas, A.: Effect of initial moisture content on the yields of oily products from pyrolysis of biomass. J. Anal. Appl. Pyrol. 71(2), 803–815 (2004)

Reddy, P.J.: Municipal Solid Waste Management: Processing—Energy Recovery—Global Examples. Book Syndicate, Kolkata (2011)

Baker, C.G.J., Baker, C.: Industrial Drying of Foods. Springer, Berlin (1997)

Mujumdar, A.S.: Handbook of Industrial Drying, 4th edn. Taylor & Francis, Park Drive (2014)

Acknowledgments

Junmeng Cai and Wenfei Cai would like to acknowledge the financial support from the IRSES ECOFUEL programme (FP7-PEOPLE-2009-IRSES Grant 246772). Yang Yang would like to acknowledge the support from the EPSRC Supergen Bioenergy Challenge “PyroAD” Project (EP/K036793/1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Appendix: MATLAB Code for the Objective Function (ObjectiveFunction.m)

Appendix: MATLAB Code for the Objective Function (ObjectiveFunction.m)

Rights and permissions

About this article

Cite this article

Cai, J., Yang, Y., Cai, W. et al. Drying Kinetic Analysis of Municipal Solid Waste Using Modified Page Model and Pattern Search Method. Waste Biomass Valor 8, 301–312 (2017). https://doi.org/10.1007/s12649-016-9570-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9570-9