Abstract

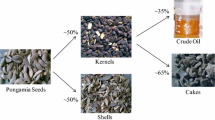

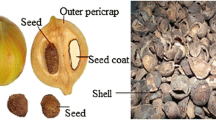

Thermochemical gasification characteristics of Jatropha shells were investigated in this study. Jatropha shells were gasified in a downdraft wood gasifier for two air nozzles opened and top opened condition. The temperature variation in the various zones of the gasifier was measured during gasification process. Operating parameters were calculated for the gasifier. Producer gas generated from gasification of Jatropha shells has low calorific value (2.55 MJ/Nm3) as compared to the wood (4.48 MJ/Nm3). The gasification efficiency or coefficient of thermal conversion was 64 % for shells which is lower than that of wood gasification which was 84 %. The complete gasification of shells could not be achieved because of low bulk density and irregular shape. Jatropha shells are not suitable for gasification in downdraft open top gasifier.

Similar content being viewed by others

References

Gani, A., Naruse, I.: Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew. Energy 32, 649–661 (2007)

Sudha, P., Ravindranath, N.H.: Land availability and biomass production potential in India. Biomass Bioenerg. 16, 207–221 (1999)

Balat, M.: Gasification of biomass to produce gaseous products. Energy Sources Part A 31, 516–526 (2009)

Basu, P.: Biomass gasification and pyrolysis practical design and theory. Academic Press, Elsevier (2010)

Demirbas, A.: Current technologies for the thermo-conversion of biomass into fuels and chemicals. Energy Sources 26, 715–730 (2004)

Cheng, J.: Biomass to Renewable Energy Processes. Boca Raton, CRC Press, ISBN 978-1-4200-9517-3, pp. 465–470

Erkiaga, A., Lopez, G., Amutio, M., Bilbao, J., Olazar, M.: Syngas from steam gasification of polyethylene in a conical spouted bed reactor. Fuel 109, 461–469 (2013)

Miccio, F., Ruoppolo, G., Kalisz, S., Andersen, L., Morgan, T.J., Baxter, D.: Combined gasification of coal and biomass in internal circulating fluidized bed. Fuel. Proc. Tech. 95, 45–54 (2012)

Kern, S., Pfeifer, C., Hofbauer, H.: Gasification of wood in a dual fluidized bed gasifier: influence of fuel feeding on process performance. Chem. Eng. Sci. 90, 284–298 (2013)

Link, S., Arvelakis, S., Paist, A., Martin, A., Liliedahl, T., Sjostrom, K.: Atmospheric fluidized bed gasification of untreated and leached olive residue, and co-gasification of olive residue, reed, pine pellets and Douglas fir wood chips. Appl. Energy 94, 89–97 (2012)

Vera, D., de Mena, B., Jurado, F., Schories, G.: Study of a downdraft gasifier and gas engine fueled with olive oil industry wastes. Appl. Therm. Eng. 51, 119–129 (2013)

Prasad, L., Subbarao, P.M.V., Subrahmanyam, J.P.: Pyrolysis and gasification characteristic of pongamia residue(de-oiled cake) using thermogravimetry and downdraft gasifier. Appl. Therm. Eng. 63, 379–386 (2014)

Susastriawan, A.A.P. : Development of technologies for complete utilization of waste of oil seed collections (M.Tech. Thesis), mechanical engineering department, indian institute of technology Delhi, New Delhi (India), 2009

Yin, R., Liu, R., Wu, J., Wu, X., Sun, C., Wu, C.: Influence of particle size on performance of a pilot-scale fixed-bed gasification system. Bioresour. Technol. 119, 15–21 (2012)

Tinaut, F.V., Melgar, A., Horrillo, A., Rosa, A.D.: Method for predicting the performance of an internal combustion engine fuelled by producer gas and other low heating value gases. Fuel. Proc. Tech. 87, 135–142 (2006)

Iyer, P.V.R., Rao, T.R., Grover, P.D.: biomass-thermo chemical characteristic, chemical engineering department, IIT Delhi, 3rd Edition (2002)

Singh, R.N., Bhoi, P.R., Patel, S.R.: Modification of commercial briquetting machine to produce 35 mm diameter briquettes suitable for gasification and combustion. Renew. Energy 32, 474–479 (2007)

Dogru, M., Howarth, C.R., Akay, G., Keskinler, B., Malik, A.A.: Gasification of hazelnut shells in a downdraft gasifier. Energy 27, 415–427 (2002)

Gottipati, M., Mishra, S.: A kinetic study on pyrolysis and combustion characteristics of oil cakes: effect of cellulose and lignin content. J Fuel Chem Technol. 39(4), 265–270 (2011)

Chandra, R.: Studies on production of enriched biogas using Jatropha and Pongamia de-oiled seed cakes and its utilization in IC engines (Ph.D. Thesis), Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi (India), 2009

Acknowledgments

Author would like to express thanks to Prof. Bhuvanesh Gupta, Department of Textile Engineering and Prof. P.M.V. Subbarao, Department of Mechanical Engineering, Indian Institute of Technology Delhi, New Delhi for providing necessary help during the course of the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasad, L. Experimental Study on Gasification of Jatropha Shells in a Downdraft Open Top Gasifier. Waste Biomass Valor 6, 117–122 (2015). https://doi.org/10.1007/s12649-014-9321-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-014-9321-8