Abstract

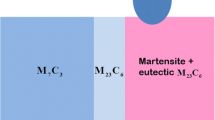

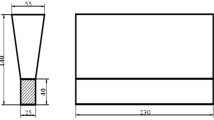

Grinding plates produced with silicon-grey cast iron wear out quickly. As a result of this molten grey iron is treated with ferrochrome to produce hard and wear resistant grinding plates. This makes the cost of the grinding plates very expensive for the rural community to purchase them for their domestic grinding operation. Because of this limitation this present research study looks at the effect of snail shell powder on the properties of grey cast iron with a view to using it as an alternative to conventional ferrochrome for the production of grinding plates. The grey cast iron scraps were melted in a crucible furnace. Ladle treatment of the molten metal was done by varying the percentage of snail shell powder from 0.1 to 0.5. The same process was repeated for ferrochrome to serve as a control. The molten metal was poured into a prepared sand mold. The microstructure, spectrometer analysis, hardness, wear and tensile properties were studied. The results show that the tensile strength increased with increasing snail shell powder up to a maximum value of 0.4 % and the hardness values increased linearly as the snail shell powder increased, while the wear rate decreased continuously with increasing composition of snail shell powder. The microstructure of all a samples showed the network of interdendritic cementite (white) surrounded by patches of pearlites. The practical test of the grinding plates was conducted and found that the developed grinding plates gave 96.7 % efficiency. The results obtained for the snail shell powder samples compare favorably with conventional ferrochrome. This work has established that snail shell powder can be used as an alternative to ferrochrome for the production of white cast iron for grinding plate’s application.

Similar content being viewed by others

References

Mcniven S (2010) Creating wear resistance catings. Columb Steel Cast Comp Limit 34:890–894

Robert RB (1999) FOESCO ferrous, Foundry me handbook program. Butterworth-Heinemann, ISBN: 7506-4284, pp 68–69

FOSECO (1994) FOSECO: Foundry man handbook 7th edition (online) available FTP. wwwsciencedirect/castironproduction, pp 456–459

Elkem AS (2011) Foundry: overview of the alloying elements and their effect in grey iron. Tech Inf 12A and 12B 3:1–8

Chen S-Z, Lin J-HC, Ju C-P (2003) Effect of aluminum content on tribological behavior of a Cu-Fe-C based friction material sliding against FC30 cast iron. Mater Trans 44:787–793

Sugishita J, Fujiyoshi S (1981) The effect of cast iron graphites on friction and wear performance i: graphite film formation on grey cast iron surfaces. Wear 66:209–221

Scandian C, Boher C, de Mello JDB, Rézaï-Aria F (2009) Effect of molybdenum and chromium contents in sliding wear of high-chromium white cast iron: the relationship between microstructure and wear. Wear 267:401–408

Agunsoye JO, Ochulor EF, Talabi SI, Olatunji S (2012) Effect of manganese additions and wear parameter on the tribological behaviour of NFGrey (8) cast iron. Tribol Ind 34:239–246

Atanda P, Oluwadare G, Oluwole O (2011) Effect of silicon content and shake-out time on hardness and grain size properties of GL 250 cast iron. J Min Mater Charact Eng 10:257–266

Agunsoye JO, Talabi SI, Awe O, Onwuegbuzie AT (2013) Effect of silicon additions on the wear properties of grey cast iron. J Min Mater Charact Eng 1:61–67

Pluphrach G (2010) Study of the effect of solidification on graphite flakes microstructure and mechanical properties of an ASTM a-48 gray cast iron using steel molds. Songklanakarin J Sci Technol 32(6):613–618

Atuanya CU, Aigbodion VS (2014) Effect of wear parameter on wear behavior of recycled polyethylene/snail shell waste particulate bio-composites. J Fail Anal Prevent 14:509–518

Metal ASM (2005) Handbook properties and selection irons, steel, and high-performance alloys (cast Iron) 1:35–37

Zhang J, Gao Y, Xing J, Ma S, Yi D, Yan J (2009) Effects of chromium addition on microstructure and abrasion resistance of Fe–B cast alloy. Tribol Lett 71:789–794

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aigbodion, V.S., Isah, L.A., Achiv, F.M. et al. Anti-Wear Enhancement of Silicon-Grey Cast Iron for the Production of Grinding Plates: Effect of Snail Shell Powder as Carbide Forming Material. Silicon 10, 421–430 (2018). https://doi.org/10.1007/s12633-016-9467-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-016-9467-z