Abstract

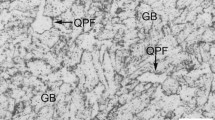

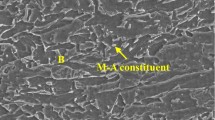

The continuous cooling transformation curve of heat-affected zone (HAZ) of X70 pipeline steel was measured by Gleeble-3500 thermal mechanical simulator, optical microscope (OM) and hardness analysis. The microstructure transformation rule at different cooling rates and solution behaviors of microalloy carbonitride during heating process of simulated specimens were investigated. When the cooling rate changes from 10 to 20 °C·s−1, microstructures at HAZ are identified as granular bainite, lathy bainite, and quasi-polygonal ferrite. This microstructure is featured with fine ferrite grains, martensite/austenite islands dispersed, high-density dislocations, and fine carbonitride particles, resulting in improving the strength and toughness of HAZ. With the cooling rate increasing to above 40 °C·s−1, the microstructure is predominantly coarse lathy bainite with clear primary austenite grain boundary. While the cooling rate decreases to below 1 °C·s−1, a fairly small amount of pearlite can be observed at the boundaries. The strength and toughness of HAZ are deteriorated because of coarse grains among these microstructures. Most of microalloy carbonitrides in HAZ could be dissolved in the matrix during heating process. A few of TiN particles existing as residues in the matrix can prevent austenite grain from growing, and then improve the strength and toughness of HAZ.

Similar content being viewed by others

References

Zheng L, Gao S. Research and development of X70 coils for large diameter pipes of west-east gas pipeline project. J Iron Steel Res Int. 2006;18(3):46.

Chen QJ, Kang YL, Sun H, Yu H. Static-recrystallization behavior of hot deformation austenite in X70 pipeline steel. J Univ Sci Technol B. 2007;29(12):1212.

Zhang HM, Wang HB, Liu ZY, Liu XH, Wang GD. Study on the grain refinement mechanism of low carbon microalloyed steels for pipeline alllicatios. Trans Mater Heat Treat. 2006;27(6):99.

Chen YH, Wang Y. Effect of second thermal cycle on the microstructure of the coarse grain heat-affected zone of in-service welded pipeline steel. J Univ Sci Technol B. 2008;30(9):1002.

Xue XH, Zhou Y, Qian BN, Li JL, Lou SN. Coarse grain heat affect zone microstructures and toughness of X80 pipeline steel. J Shanghai Jiaotong Univ. 2003;37(12):1854.

Chen XW, Tian P, Wen K, Li ZH, Xiao FR, Wang X, Liao B. Study on microstructure and toughness of heat-affected zone of X70 pipeline steel. Met Hotworking Technol. 2007;36(11):6.

Chen XW, Xiao FR, Liao B, Wang X, Wang JM. Microstructure and performance forecast and welding process optimization model of HAZ of X70 pipeline steel. Met Hotworking Technol. 2007;36(3):10.

Jia KN, Wang HD, Wang H. Thermal simulating the microstructure in weld heat affected zone of calcium microalloyed C-Mn steel and its effect on toughness. Heat Treat Met. 2008;33(2):24.

Xu XL, Xin XX, Shi K, Zhou Y. Influence of welding thermal cycle on toughness and microstructure in grain-coarsening region of X80 pipeline steel. Trans China Weld Inst. 2005;26(8):69.

Moon J, Lee C. Behavior of (Ti, Nb)(C, N) complex particle during thermomechanical cycling in the weld CGHAZ of a microalloyed steel. Acta Mater. 2009;57(7):2311.

Zhao MC, Yang K, Xiao FR, Shan YY. Continuous cooling transformation of undeformed and deformed low carbon pipeline steels. Mater Sci Eng. 2003;A355(1–2):126.

Wang Y, Han T, Liu M. Local brittleness of weld heat-affected zone of X70 pipeline steel. J Mater Eng. 1999;44(10):14.

Zhou X, Liu SH, Duan YW, Wang B. Effect of t 8/5 on the coarse grain zone of HAZ properties for X70 pipeline steel. Welded Pipe Tube. 2008;31(6):22.

Cai XJ, Lin ZY, Meng XQ, Jiang JJ, Liu F, Feng SL. Experiment on the toughness of weld joint of X70 pipeline steel. Res Explor Lab. 2013;32(8):33.

Wang CM, Wu XF, Liu J, Xu NA. Precipitates in X70 pipeline steel. J Univ Sci Technol B. 2006;28(3):253.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51274083), the Natural Science Foundation of Hebei Province (No. E2013209228), the Innovation Team Leading Talent in Universities Cultivation Plan of Hebei Province (No. LJRC007), and the Science and Technology Project of Tangshan City (No. 131302108b).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Liang, JL., Feng, YL. et al. Microstructure transformation of X70 pipeline steel welding heat-affected zone. Rare Met. 33, 493–498 (2014). https://doi.org/10.1007/s12598-014-0344-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0344-x