Abstract

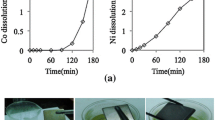

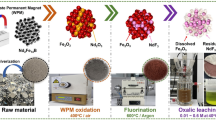

High-purity Nd metal was recovered from waste Nd–Fe–B magnet by the molten salt electrowinning process with chemical pretreatment. X-ray diffraction (XRD), scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), cyclic voltammetry (CV), chronopotentiometry (CP), and inductively coupled plasma-atomic emission spectrometer (ICP/AES) were used to characterize the deposit and electrochemical behaviors. The results show that NdF3 is effectively synthesized from the Nd–Fe–B magnet using HCl solution and NH4F. During the chemical treatment of the waste magnet, iron impurity is eliminated as a soluble [NH4]3[FeF6] complex. Electrowinning using NdF3 in LiF molten salt shows that Nd metal is deposited from the electrolyte on the cathode at the reduction potentials ranging from −1.48 to −1.35 V (vs. W) with the concentration change of NdF3. The final purity of Nd metal deposit is higher than 99.78 %.

Similar content being viewed by others

References

Sharma RA, Seefurth RN. Metallothermic reduction of Nd2O3 with Ca in CaCI2–NaCI melts. J Electrochem Soc. 1988;135(1):66.

Velu PT, Reddy RG. Calciothermic reduction of neodymium fluoride. In: Proceeding of technical sessions presented by the TMS Aluminum Committee at the 134th TMS Annual Meeting, San Francisco; 2005. 13.

Kipouros GJ, Sharma RA. Electrolytic regeneration of the neodymium oxide reduction-spent salt. J Electrochem Soc. 1990;137(11):3333.

Castrillejo Y, Bermejo MR, Barrado E, Martinez AM, Arocas PD. Solubilization of rare earth oxides in the eutectic LiCl-KCl mixture at 450 °C and in the equimolar CaCl2–NaCl melt at 550 °C. J Electroanal Chem. 2003;545(27):141.

Stefanidaki E, Hasiotis C, Kontoyannis C. Electrodeposition of neodymium from LiF–NdF3–Nd2O3 melts. Electrochim Acta. 2001;46(17):2665.

Hu XW, Wang ZW, Shi ZN Gao BL, Lu GM, Cui JZ, Cao XZ Zhang B. Electrical conductivity and Nd solubility of NdF3–LiF–Nd2O3 melts. In: Proceeding of the Characterization of Minerals, Metals and Materials, Orlando; 2007. 79.

Chen SG, Yan XY, Tu ZX, Lu QT. Cathodic process of Nd and its dissolution behavior in molten fluoride. Rare Met. 1994;13(1):46.

Zhang YH, Ren HP, Yang T, Zhao C, Chen LC, Shang HW, Zhao DL. Electrochemical performances of as-cast and annealed La0.8 − xNdxMg0.2Ni3.35Al0.1Si0.05 (x = 0–0.4) alloys applied to Ni/metal hydride (MH) battery. Rare Met. 2013;32(2):150.

Murphy JE, Dysinger DK, Chambers MF. Electrowinning neodymium metal from chloride and oxide–fluoride electrolytes. In: Proceedings of the Technical Sessions Presented by the TMS Light Metals Committee at the 123rd TMS Annual Meeting, San Francisco;1994. 137.

Pressouyre GM. Trap theory of hydrogen embrittlement. Acta Metall. 1980;28(7):895.

Harriselu IR, McGuiness PJ. Hydrogen: its use in the processing of NdFeB-type magnets. J Less-Common Met. 1991;172–174(3):1273.

Rivoirard S, Noudem JG, de Rango P, Fruchart D, Liesert S, Soubeyroux JL. Anisotropic and coercive NdFeB powder for bonded magnets. In: Proceeding of the 16th International Workshop Rare-Earth Magnets Their Application Sendai; 2000. 347.

Burns VSJ, Williams AJ, Harris IR. Production of anisotropic powder from hot deformed RE–Fe–B–Cu alloys. In: Proceeding of 16th International Workshop Rare-Earth Magnets Their Application Sendai; 2000. 355.

Itoh M, Masuda M, Suzuki S, Machida KI. Recycling of rare earth sintered magnets as isotropic bonded magnets by melt-spinning. J Alloys Compd. 2004;374(1–2):393.

Asabe K, Saguchi A, Takahashi W, Suzuki RO, Ono K. Recycling of rare earth magnet scrape. Part I. Carbon removal by high temperature oxidation. Mater Trans. 2001;42(12):2487.

Zakotnik M, Harris IR, Williams AJ. Multiple recycling of NdFeB-type sintered magnets. J Alloys Compd. 2009;469(1–2):314.

Suzuki RO, Saguchi A, Takahashi W, Yagura T, Ono K. Recycling of rare earth magnet scraps. Part II. Oxygen removal by calcium. Mater Trans. 2001;42(12):2492.

Xu Y, Chumbley LS, Laabs FC. Liquid metal extraction of Nd from NdFeB magnet scrap. J Mater Res. 2000;16(11):2296.

Li L, Yu Y, Meng F, Tan Y, Hamers RJ, Jin S. Facile solution synthesis of α-FeF3·3H2O nanowires and their conversion to α-Fe2O3 nanowires for photoelectrochemical application. Nano Lett. 2012;12(2):724.

Hamela C, Chamelot P, Taxil P. Neodymium(III) cathodic processes in molten fluorides. Electrochim Acta. 2004;49(25):4467.

Stefanidaki E, Hasiotis C, Kontoyannis C. Electrodeposition of neodymium from LiF-NdF3-NdO3 melts. Electrochim Acta. 2001;46(17):2665.

Acknowledgments

This work was financially supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) of the Korea Government Ministry of Knowledge Economy (No. 20122010300041) and the National Research Foundation of Korea (No. 2011-0091839).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ryu, HY., Lee, JH., Kim, WG. et al. Electrochemical behavior of Nd in its pyrometallurgical recovery from waste magnet. Rare Met. 34, 111–117 (2015). https://doi.org/10.1007/s12598-014-0241-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0241-3