Abstract

Purpose

There is limited up-to-date knowledge about the monetary valuation of improved reliability for freight transports. This means that the benefits of reduced variability in transport time are not properly taken into account in cost-benefit analysis relating to, for example, infrastructure investments.

Methods

We develop on a conceptual level an estimation approach for the value of reduced transportation time variability (VTTV) related to the cargo component based on precautionary and operative delay costs. This approach is inspired by the safety stock approach but includes more general precautionary measures that firms take to avoid stock-out costs. This paper presents the analysis of a Swedish grocery company’s transports by shuttle train as a case study. First, the distribution of the arrival times of the shuttle train is analyzed in order to estimate the transportation time variability for the firm. Second, precautionary costs for measures undertaken to manage and mitigate the transportation time variability are estimated and the additional operational costs that occur in case of major delays are calculated.

Results

It is found that the 10 % worst delays contribute to more than half of the total train delays, showing that actual transportation times exhibit a heavily skewed distribution with fat tails, indicating that the standard deviation might not be a sufficient measure of transport time variability. The calculated VTTV related to the cargo component based on the precautionary costs is around €4 per delay-tonne-hour and around €2.2 per standard deviation of transportation time.

Conclusions

We show that by conducting a case study it is possible to get VTTV estimates for the cargo component valid for a specific company. In conclusion, assuming a high degree of transport market concentration with regard to shippers, a limited number of case studies for key companies in the market might be sufficient to get a representative VTTV measure. We therefore advocate further case studies and research aimed at getting more inputs from firms that send and receive goods. More research should also be done on how to incorporate risks for delays and the extremeness of empirical delays in transport models and VTTV definitions.

Similar content being viewed by others

1 Introduction

There is limited up-to-date knowledge about the monetary valuation of improved reliability for freight transports. This means that the benefits of reduced variability in transport time are not properly taken into account in cost-benefit analysis (CBA) relating to, for example, infrastructure measures.Footnote 1 Compared to the value of transport time savings (VTTS), the value of transport time variability (VTTV) is hardly addressed in cost-benefit analysis despite intentions in this direction in several countries OECD/ITF [1]. Up to now only a few countries have incorporated the benefits according to improved reliability in their CBA-guidelines; provisional recommendations are available in the Netherlands, Sweden and Norway [2].

The VTTV related to freight transports comprises the cargo component (related to the sender or receiver of the cargo) and the transport costs component (related to the carrier).Footnote 2 Different definitions of VTTS and VTTV and practices in relation to CBA that differ between countries can lead to misunderstandings (for example double counting of cost components) and complicate value transfers between countries [2]. In this paper we focus on the VTTV related to the cargo component. We include studies with different VTTV-definitions in our literature review below, but focus on the VTTV related to the cargo and vehicle component in the remaining paper.

Several approaches have been suggested for the estimation of VTTV since variability itself is not directly traded in the market place: i) based on revealed preference (RP) techniques for the US: [3]), ii) based on stated preferences (SP) techniques (for Sweden: [4–8]; for Norway: [9,10]; for Finland: [11]; for the Netherlands: [12–19]; for the UK: [20–22]; for France: [23], for the US: [24]; and for Australia: [25,26]), iii) based on calculations of costs for safety stocks required because of stochastic transport times (for Sweden and Norway: [27,28]; see also [29]).

Significance et al. [30] performed a literature study for reliability in passenger and freight transport on behalf of the German transport ministry. Based on the evaluation of 32 studies related to passenger transport and 11 studies to freight transport it is confirmed that, up to now, SP techniques have been employed nearly exclusively to derive monetary estimates of VTTV. RP techniques have failed due to lack of data on travel time variability, transport costs and available but not chosen alternatives as well as the correlation between attributes. Significance et al. [30] conclude that the RP approach is only possible in exceptional cases (i.e. when comparing a toll road with reliable travel times and a toll-free route with less reliable, often much longer travel times). Sometimes RP and SP data are used together to make use of the benefits of both techniques. Lack of data is also a problem for the safety stock approach.

Based on these outcomes and the views of critics of the use of the SP- and RP- technique for freight transports [31]Footnote 3 we develop the precautionary and operative costs approach. This approach is inspired by the safety stock approach but includes different – more general – precautionary measures that firms take to avoid stock-out costs.

Regardless of the organization of the transport, the benefit of reduced transport time variability is related to the impact on costs of the sender and/or receiver of the goods. There are basically two issues when it comes to the VTTV for infrastructure measures: The first is to find the change of transport time variability for a certain link or node in the supply chainFootnote 4 that is attributable to a specific infrastructure investment or maintenance project. Little guidance is available on how the impact of infrastructure measures on the transport time variability may be estimated. There are various sources for time variability for transports that go either direct or via transhipment points from a sender to a receiver. The sum of the variations adds up to the total transport time variability during the transport. The second issue is to calculate the VTTV for the cargo transported on the part of the infrastructure that is addressed.

The goods flows in a base scenario, which describes the existing infrastructure, and a reference scenario, where a specific infrastructure measure or package is included, are typically calculated with help of transport models. Both the Norwegian and the Swedish national freight models include an aggregated-disaggregated-aggregated logistics module [32]. This module makes it possible in principle to calculate the benefits due to less variability in transport time by making use of the trade-off between transport costs on one side and inventory and order costs on the other side. However, information on demand, standard deviations for transports times and stock-out costs are needed as input [33].

When it comes to transport time variability, several definitions are possible. Variability can be calculated as the standard deviation of the transport time distribution, comprising too late and too early arrivals. One reason for choosing this definition is that standard deviations are relatively easy to integrate into transport models. Variability can also be defined as expected delays, excluding early arrivals, or as risks for delays of a certain magnitude. One question is how cancelled transports should be treated – for example, should they be considered as very long delays. In the German context BVU & TNS [34] distinguish between different factors that can cause unreliable transports: organisational (i.e. not available vehicle), human (i. e. accidents caused by tired drivers), stochastic (i.e. extreme weather) and infrastructure related (i.e. overloaded roads). They further state that only the later can reflected in models. In the estimation of the VTTV below we do include all causes and do not differentiate between them.

This paper presents and implements empirically the precautionary costs approach in a case study, in order to examine the feasibility to derive the VTTV related to the cargo component for Swedish rail freight transports using this approach. The main focus is on supply chains that include rail, as rail causes most reliability problems in Sweden [35].Footnote 5 In section 2 the ideas behind the modelling framework for the precautionary costs approach are presented. Our focus is on delays; too early arrivals are not addressed. Section 3 addresses the grocery company COOP Sweden AB (COOP), which has switched from road transports to intermodal road-rail transports. The new transport concept (section 3.1) and the transportation time variability in the form of train delays and cancellations that COOP faced during a 16-month period (section 3.2) are described. Finally, it is shown which precautionary costs COOP pays in connection with the new system for minimizing the stock-out costs and which operative costs COOP needed to pay as a result of major train delays and cancellations during the 16-month period. The VTTV related to the cargo component is calculated on the basis of COOP’s precautionary costs and the standard deviation for the transport time of the train. Section 4 concludes the paper with discussion and an outline for future research.

2 The conceptual framework: precautionary and operative costs

The purpose of this paper is to analyze for a specific case different types of costs incurred due to delays, to measure delays, and to make a distinction between and compare the ex ante (before the fact) precautionary costs that COOP has been willing to take on and the ex post (after the fact) costs due to incurred delays. In general it is hard to measure the value of marginal improvements in reliability. Our main argument is that in equilibrium the firms have adapted to the current status quo, so that the firm’s marginal cost of insurance against delays (what we here call precautionary measures) should be equal to the marginal cost of the delays at the present state of reliability. Hence, the marginal costs can in principle be observed by looking at buffer stock size choices and required service levels. However, not all companies have a logistics system using buffer stocks. We therefore analyze a grocery company in order to see another way to handle handle transport time variability.

We distinguish three different kinds of cost associated with the variation in transportation time: precautionary costs to avoid or mitigate the consequences of delays in general; operational costs that are caused by measures that have to be taken in case of delays and stock-out costs.

Precautionary costs

arise when measures are taken in advance that mitigate the consequences of delays or the probability and size of delays and therefore have insurance-like characteristics. The main precautionary cost previously examined is keeping a safety stock, so that if goods arrive too late at the receiver, there are still enough units in stock to satisfy the demand in sales, so that this process does not come to a halt. Another type of stock-out cost can occur when a producing firm runs out of inputs.

Of course, keeping a safety stock is not costless since costs arise for staff, physical storage capacity and capital that is tied up. Hence, companies try to minimize safety stock while maintaining a sufficient service level. However, inventories are not the only precautionary measure that can be taken. The acceptance of additional transport and/or planning costs can also be precautionary measures (see COOP case study in the next section for details). Physical agglomeration between buyer and seller of intermediate goods and the choice of more reliable (and more expensive) modes of transport by road instead of rail are other major precautionary costs to prevent adverse effects due to rail delays. In summary, precautionary measures might target the probability of delays (e.g. maintenance), the size of delays (e.g. physical agglomeration) or the consequences of delays (e.g. insurance or safety stocks). In general, two components of uncertainty can be identified for freight transports: i) variations in the lead time taken between the order and the delivery of the cargo, where the transport time is part of the lead time, and ii) variations in demand. Both can be dealt with by using precautionary measures. In this paper we assume that demand is deterministic, so that the undertaken precautionary measures can be attributed solely to stochastic transportation times.

Operational costs

are costs associated with too late arrivals of the cargo that can be associated with a specific delay after the delay materializes – for example, the costs of booking other freight carrier or overtime compensation for workers.

Stock-out costs

are costs that arise when the inventory is exhausted. For retailers this means loss of sales (and hence less revenues); for suppliers it means loss of revenues or fines. For producers it means that production has to stop because they run out of an input, causing higher production costs, lost sales or fines.

Precautionary costs, operational costs and stock-out costs are closely related. When determining the level of precautionary measures, the operational and stock-out costs due to delays are taken into account. The more precautionary measures that are taken, the fewer the operational costs will be later on. However, once precautionary measures are fixed, operational and stock-out costs arise for every delay that occurs (for the part of delay costs not covered by the precautionary measures).

Hence, there is a trade-off between precautionary costs and future operational and stock-out costs: incurring more precautionary costs now means lower future cost of variability; the company will buy insurance in the form of precautionary measures as long as the marginal cost of doing so is lower than the expected marginal benefits of saved variability costs due to the precautionary measures. It can be seen as the price paid for a delay-related insurance with an option-like payoff structure for each transport: the payoff from the insurance is zero as long as actual time < planned time, but has a positive payoff as actual time > planned time. The payoff of the insurance policy is: max[f(tACTUAL-tPLANNED), 0], the payoff from a so-called put option. Hence, the company pays a price for a put option now to get insurance against future delay related downside risk. A central insight from option theory is that the contract price is increasing with respect to variability. The number of purchased insurance contracts depends on the expected delay costs: additional contracts are bought till the marginal insurance cost equals the marginal delay cost.

This implies that the VTTV for a small reliability improvement is equal to the saved marginal costs of precautionary measures in the cost minimization optimum, given the estimated variability (measured by the standard deviation σ) for either a specific combination of route and mode or for the transportation network in general. Expressed formally, we have in optimum: c′(σ) = E[v′(σ)] > 0, where c′(σ) is the marginal cost for precautionary measures that ensure a sufficiently reliable logistics system for the firms and E[v′(σ)] is the expected marginal cost of variability. We assume that both c′(σ) and E[v′(σ)] are increasing with σ.

As the firms’ expected marginal costs of variability are difficult to estimate, we think that a more promising approach is to estimate the marginal cost of precautionary measures for a given variability in the transport system. The marginal cost of precautionary measures might be computed from a theoretical model for buffer stocks or buffer time with appropriately estimated parameter values; here, however, we take as a proxy for marginal costs the average costs for precautionary measures and relate the average costs to different measures of variability. Assuming that average costs can approximate marginal costs, the marginal cost for precautionary measures is observable given appropriate company data, since firms are investing in their logistic systems to handle the variability in transportation times they are facing.

3 Case study from the grocery sector

3.1 COOP’s logistic system

The grocery company COOP transports about 3.5 million cubic metresFootnote 6 of grocery items, refrigerated and frozen food and non-food products per year in Sweden.Footnote 7 The company’s warehouses are located close to Stockholm: in Bro for non-refrigerated foods and non-food products, in Västerås for refrigerated food and in Enköping for frozen food. For incoming products from outside Sweden different predominantly intermodal transport chains are used. The port of Helsingborg in the south of Sweden is one of the main import ports. A high proportion of the incoming products are transported to the warehouses via Helsingborg. The products are assembled in the warehouses and go from there to COOP’s over 700 Swedish stores. The distance between Helsingborg and the warehouses in the Stockholm area is about 600 km (see Fig. 1).

Traditionally, COOP bought in all its products and services, including transport. However, in 2009 the company made an effort to ensure control over their incoming and outgoing transports and developed among other changes a combined road-rail system. We explore this in section 3.3.

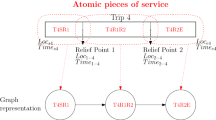

Since September 2009 two shuttle trains carrying 36 trailers move 5 days a week between Helsingborg and Bro. With the northbound train, suppliers send goods and the warehouse in Bro is the receiver. With the southbound train, the warehouse sends assembled goods and the shops in the south of Sweden are the receivers. The southbound train has stops in Alvesta (about 150 km north of Helsingborg) and Helsingborg. According to information from COOP based on the rail operator’s coding for the period 1 June 2011 to 29 February 2012, the infrastructure holder, the Swedish Transport Administration, was responsible for more than half of the delays (55 %). The share was at 88 % highest in January 2012 and was higher for the northbound train (61 %) than for the southbound train (41 %). The delays were caused by a wide range of different factors – problems related to the electricity system, the signal system, the switches, derailments, and construction works. The rail operator was responsible for 16 % of the delays. COOP, as sender of the goods, caused 8 % of the delays. Twenty-one percent of the late arrivals were due to other reasons, like weather conditions, elk on the track, and copper theft.

The warehouse in Bro has access to the rail network via an industrial track. The southbound train is part of an intermodal transport chain: the trailers are transferred to trucks and transported to the shops in Småland (from the railway station in Alvesta) and Skåne (from the railway station in Helsingborg).

COOP planned to use the shuttle train to also carry highly time-sensitive fresh fruits and vegetables. A trial was started but discontinued after two major breakdowns. Today these transports are performed by truck. Bread and milk products, which represent a high volume percentage of the products sold in COOP’s shops, are transported in separate systems.

3.2 Transport time variability data

COOP has kindly provided us with data that describe the performance of the two shuttle trains between Helsingborg and Bro for the period 1 June 2011 to 30 September 2012. Assuming an average of 29 loaded trailers per trainFootnote 8 and around 10 tonnes per trailer, the two trains have transported around 200,000 tonnes or 74,000 cubic metres during the 16-month period.

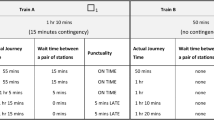

Between June 2011 and September 2012 both the northbound and southbound trains were cancelled twice due to a heavy storm in the end of November 2011. The average delays were moderate but there were several delays of over and below one hour: the northbound trains arrived in Bro more than 1 h too late on 53 occasions (15 %). The southbound train was more than 1 h too late in Alvesta on 27 occasions (8 %) and more than 1 h late in Helsingborg on 48 occasions (14 %).Footnote 9 Arrival delays of more than an hour lead to major problems for the warehouse in Bro and – even more seriously – the shops in the south of Sweden. Major delays in Helsingborg or Bro also cause problems for the rail operator as the shuttle train cannot turn around as planned. COOP does not experience problems related to too-early trains. Figures 2 and 3 show that many trains arrived up to nearly 2 h before schedule.

Table 1 shows the means and the standard deviations (excluding cancellations) for the stations that the shuttle train serves.

The mean, exclusive of early arrivals, is the conditional expectation given that we have a delay. The standard deviation, excluding early arrivals, is the so-called lower partial standard deviation (LPSD) or the square root of the semi-variance. It uses only negative deviations from the time-table, squares those deviations to obtain a semi-variance and takes the square root to get a standard deviation for the left-tail. The LPSD is therefore the square root of the average squared deviation, conditional on a negative outcome (late arrival). The LPSD does not capture, however, the frequency of delays.

The figures in Table 1 also show that the average delays, including too-early arrivals, are relatively small (9 to 24 min) and the average delays (excluding too-early arrivals) are more substantial (38 to 53 min). Hence, it is necessary to study the real distribution of the delays (see Fig. 4) and the risks for large delays that firms that are senders and receivers of goods, like COOP in our case study, face.

The standard deviation (including early arrivals) for the transport time of COOP’s shuttle train is lower (on average 63.3 min) than the standard deviation for freight trains in Sweden (of 76.5 min, see [35]). The skewness is −4.65 going south and −4.94 going north (the normal distribution has a skewness of zero) and the kurtosis is 39.55 going south and 39.46 going north (the normal distribution has a kurtosis of 3).

Table 2 shows that the average delay in the 90th percentile was around 2.5 h and that the 10 % worst delays contributed to more than half of the total delays going south and almost two-thirds of total delays going north. In a sense, Table 2 quantifies the risk for COOP of using rail instead of road if road is showing no, or a very low degree of, variability in transportation time.

If we take southbound transports to Helsingborg as an example, in 5 % of all transports the delay is almost 2 h (118.9 min) or more according to the percentile value. That is, once per 20 transports a delay of this size or larger is expected to happen southwards, and since there are two trains per day (one northbound and one southbound), it means that once every 10 days or three times a month a delay of this magnitude occurs. The average delay in each percentile is the conditional tail expectation (CTE). For example, going north to Bro there is a 10 % probability of a delay of at least 1 h. The average within the percentile is close to 2.5 h, so that with a 10 % probability (once every 10 transports or once every 5 days) COOP has to expect an average delay of 2.5 h. Hence, the CTE gives a better estimate of how big the risk is in the tail of the delay distribution.Footnote 10 Whereas the percentile values mark the best outcome of any given worst-case scenario (e.g. 10 % worst cases), the CTE gives the average for a given worst-case scenario.

3.3 Costs to manage transport time variability

In 2009 COOP shifted transportations from road to a combination of road and rail.Footnote 11 Ideally such a shift should not increase the overall costs, although rail transport services are in general less reliable than road services in Sweden. Below we try to estimate COOP’s precautionary costs that are measures taken in advance in order to mitigate the consequences of major delays and the operational costs that were paid as consequence of the major train delays and cancelled trains during the period June 2011–September 2012. According to our reasoning in section 2, to reach an optimum it will not generally be necessary to insure against all delay costs. The calculations below are based on information from COOP and own assumptions.

When it comes to precautionary costs, COOP did not have extra safety stock costs since the shelves in the shops, which serve as safety stocks, were assessed to be sufficiently deep and therefore did not need to be extended.Footnote 12 However, COOP had costs associated with controlling the intermodal transportation concept in form of 1a) extra personnel to manage the concept and 1b) investments in trailers that can easily be transferred from rail to road in case of major delays:

-

1

-

a)

Three out of COOP’s four transport planners work more or less full-time on the transfers from rail to road, the organization of the road transports, and the handling of the consequent effects for COOP on the turnaround of the shuttle train in case of major train delays. We calculate costs of about €235,000 for the 16-month period we study, assuming three additional planners, monthly wages (including social costs) of €4412 and €24,000 costs for office space for the three planners (€4412×16×3+€24,000).Footnote 13

-

b)

In total 72 trailers (36 per direction)Footnote 14 are used that can easily be transferred from the shuttle train to a truck in case of a major train delays. The investment costs for these transferable trailers are around €23,529 higher than for standard trailers. Based on an assumed life-span of 10 years we estimate the additional costs for the more expensive trailers to be around (72 × €23,529/10 = €169,000 per year and about €223,000 for the 16-month period.Footnote 15

In addition to the precautionary costs COOP paid operational costs during the 16-month period, additional costs in case of major delays made up of 2a) extra road transport costs, 2b) extra costs in the receiving shops, and 2c) extra costs in the receiving warehouse:

-

a)

-

2

-

a)

If we assume transfers from rail to road on the 24 occasions when the train delays were more than 2 h, an average 29 trailers per train and road transport costs of €529 per trailer (which corresponds to half the costs for a trailer transport by truck from Bro to Helsingborg), we get extra road transport costs of €368,000 (24 × 29 × €529). According to COOP, no costs fall away.

-

b)

The southbound train that serves the stores is more time sensitive than the northbound train that goes to the warehouse. If the train arrives late at the railway stations in Alvesta or Helsingborg, the trucks probably reach the stores too late as well. According to COOP, this means that the employees who pick up the products in the shops have to wait and as a consequence working hours are lost.Footnote 16 COOP assumes staff costs of about €29 per hour and that it takes about 1 h to pick up one rolling pallet. This implies extra staff costs of €403,680 if 20 rolling pallets per trailer, 29 trailer per train and 24 major delay occasions are anticipated (24 × 29 × 20 × 29).Footnote 17

-

c)

The additional staff costs in the warehouse due to late arrivals of the northbound shuttle train on 75 occasions are assumed to be much lower than for the southbound train. We assume €12,000.

-

d)

For the two cancelled trains during the 16-month period COOP estimates direct costs in the form of increased transport costs to be € 200,000.

-

a)

The estimates for COOP’s precautionary and operational costs are listed in Table 3. We have also calculated the precautionary and operational costs per tonne-hour (expressed in € per tonne-hour) based on the information that COOP experienced about 400 delay hours between 1 June 2011 and 30 September 2012 and assuming 29 trailers per train and ten tonnes per trailer. The precautionary costs of about €4 per tonne-hour are the VTTV for the transports we study. It is obvious that there is a trade-off between the precautionary and operational costs. For instance, the additional road transport costs in the case of major delays would be higher without the transferable trailers. Alternatively we can arrive at a VTTV estimate based on revealed preference data for the specific COOP case by dividing the precautionary costs by the standard deviation of the transport time. If we assume costs for precautionary measures of around €458,000 (see Table 3) and standard deviation of 63.3 min (see section 3.2), we compute a VTTV related to the cargo component of € 2.2 per hour standard deviation.

The figures in Table 3 are based on assumptions and have to be regarded with caution. However, they show COOP’s willingness to take precautionary measures such as the employment of extra staff to manage the intermodal road-rail concept and the investment in more expensive transferable trailers that can be used to reduce the costs in case of major train delays. They also show that COOP paid additional operational costs when the trains were heavily delayed or cancelled, largely explaining the difference between precautionary costs and operative costs. As mentioned above, there is clearly a trade-off between the precautionary and operational costs; it also has to be taken into account that the combined road-rail concept is quite new and there are probably learning curves for all stake holders. As an example, in October 2011 COOP engaged a rail operator for the shuttle train that uses more powerful locomotives than the operator that ran the shuttle train 2009–2011. This is expected to reduce the delays caused by leaves on the track.Footnote 18

3.4 Mode choice

For COOP’s incoming products that go to the warehouse, transportation costs are in general the most important factor for mode choice. However, for outgoing transports to the shops transport time and frequency are also important mode choice criteria. Transport time variability is seen as closely related to the frequency. Low reliability is manageable if frequency is high (see for example Vierth [36]).

Rail transports costs per tonne-km are generally estimated to be lower than road transport costs. However, it is regarded as a disadvantage that deliveries by train (containing a maximum of 36 trailers) are concentrated at one point of time and not – like deliveries by truck – spread over time. Typically, damage in intermodal transport chains is more costly than in pure truck transports, since it is often unclear where in the transport chain the damage occurred.

There is a trade-off between the exploitation of economies of scale that requires high volumes (and low frequencies) and the number of departures. Due to the relatively low frequency of the train (compared to trucks), major delays and cancellations typically lead to major consequences. According to COOP, one remedy would be to use shuttle trains jointly with other grocery companies. Many food producers are located in the south of Sweden, while several grocery companies have their warehouses close to Stockholm. This would reduce the transportation costs per unit (economies of scale can be exploited), the frequency could be increased (if several firms started shuttle trains), and the whole (larger) system would probably be less vulnerable.

As mentioned above, COOP has given up using the intermodal road-rail system for the transportations of time-sensitive fresh fruits and vegetables. This means that the reliability problems in the rail system prevent the grocery company from using the cheapest mode for a share of their transports. However, rail transport costs do probably increase when the transport time variability for rail transports is decreased.

4 Conclusions

This paper suggests the precautionary costs approach for calculating the VTTV related to the cargo component and compares the precautionary costs with the operational costs in fact incurred. The approach is applied to the Swedish grocery company COOP that uses two daily shuttle trains and trucks to transport goods from the import port in Helsingborg to the warehouse close to Stockholm and from the warehouse to shops in the south of Sweden.

The degree of transport time variability that COOP, as sender and receiver of goods, faces due to the transport time variability of the shuttle train is identified. The 10 % longest delays contributed to more than half of the total delays going to the shops and to almost two-thirds of total delays going to the warehouse. The type and amount of precautionary costs, which are undertaken to manage the transport time variability and mitigate train delays and cancellations, and extra operative costs that occur in case of major delays are identified and calculated.

It is in general difficult to discern precautionary costs, meaning the costs that arise due to potential delays, from other costs. In our case, the additional staff needed to manage delays should be independent of the choice of transport mode. However, combining different modes or adding new modes to an existing logistic system necessitates additional staff due to coordination issues, regardless of the variability of transport times. Thus it is important to separate costs due to the logistic system from costs due to transportation time variability. In this case, we were careful to ask for the number of additional staff needed to handle trains if rail has the same reliability as road transport. Our calculations are based on COOP’s cost allocations.

The calculated VTTV related to the cargo component based on the precautionary costs from the COOP case (around €4 per tonne-hour delay) is higher than the Swedish CBA-guidelines-recommended VTTV (for groceries, around €0.5 per delay-tonne-hour). The VTTV would be even higher if operational costs and costs due to two cancelled trains had been included.Footnote 19 However, at this point in time, the recommended values for VTTV in Sweden are based on an ad hoc approach in that VTTS is multiplied by the factor 2,Footnote 20 without any theoretical or empirical justification. In fact, this paper is a first stepping stone towards better estimates for VTTV. The VTTV related to the cargo component based on COOP’s precautionary costs and the standard deviation of the transport time is around €2.2 per standard deviation.

We show that by conducting a case study it is possible to get VTTV estimates for the cargo component valid for a specific company. In conclusion, assuming a high degree of transport market concentration with regard to shippers and carriers (at least in Sweden), just a few case studies for key companies in the market might be sufficient to get a representative VTTV measure. We therefore advocate further case studies and research aimed at getting more inputs from firms that send and receive goods. More research should also be done on how to incorporate risks for delays and the extremeness of empirical delays in models and VTTV definitions.

Notes

For own account transports the same firm is both shipper and carrier.

Bruzelius [31] states: “The SP- and RP-approaches are based on methods which raise a number of issues as concerns what is being measured, and therefore if estimated values are valid from an economic point of view.”

Or demand chain.

In 2009 the Swedish Transport Administration registered around 80,000 delay hours for freight trains, see Krüger et al. [35]. This corresponds roughly to 40 million tonne-delay hours given that 500 tonnes per train is assumed to be the average load. This figure is 20 times higher than the corresponding figure for road transports. The Swedish Transport Administration registered about 1,300,000 road vehicle-delay-hours due to unplanned stops over 5 minutes (and at least for all lanes in one direction) in 2010. The number of truck-delay hours is about 200,000 (assuming that 15 % of the vehicles are trucks) and the number of the tonne-delay hours is approximately two million (assuming a load of ten tonnes per truck). The delays for the sea and air transports are probably negligible. Inland waterway transports do not exist in Sweden. About 23 % of the tonne-km in Sweden are performed by rail: www.trafa.se/sv/Statistik/Transportarbete/.

About 9.4 million tonnes.

The information is based on interviews with Kjell Håkansson, COOP, in 2012.

From 1 June 2011 to 31 December 2011 the average load factor was 78 % for the northbound train and 80 % for the southbound train.

The early arrivals in Helsingborg during the period July–September 2012 can be explained by less track work during that period than in the period before.

The centile corresponds to Value-at-Risk and the conditional tail expectation corresponds to the Expected Shortfall, both risk measures frequently used in finance, where the latter has gained attention since the financial crisis of 2008.

According to COOP’s rough estimations, the rail transportation costs can be around 5 to 10 % lower than the road transportation costs. The environmental aspect is also important for COOP.

The stores get deliveries two to five times per week.

An exchange rate of 8.5 SEK/€ is used.

COOP owns in total 92 trailers.

Due to the unreliability of the rail transports COOP choose trailers and not swap bodies as cargo units. Swap bodies have a lower net weight (three tonnes; they can accommodate 18 pallets) than trailers (ten tonnes; they can accommodate 33 pallets). For COOP, in 90 % of all cases the volume of the products (rather than the weight) is the limiting factor when filling cargo units. The use of trailers with a higher net weight than swap bodies leads tentatively to higher energy costs per tonne-kilometre; these extra costs are negligible for COOP.

It can also be necessary to pay overtime costs; these are not taken into account below.

If the delays exceed 24 h, COOP expects lost revenues because customers demand products that are not available in the shops. This type of cost is not relevant as the maximum delay in the period we look at is 11 h.

See TransportNytt (2011), Nya Cooptåget klarar av lövhalkan. [Online] Available at: http://www.transportnytt.se/nyheter/item/345-coop-tagens-nya-lok-klarar-lovhalkan. Published 20 October 2012.

The reason for including these costs would be that if they are not reflected in the average precautionary costs (if they are unexpected due to extreme events), the estimated VTTV is too low.

The reason is that the relationship for passenger transportation between delay time and travel time is approximately 2 ([38], p28).

References

OECD/ITF (2010) Improving realibility on surface transport networks. OECD, Paris

Vierth I (2013) Valuation of transport time savings and improved reliability in freight transport CBA. In: Freight Transport Modelling. s.l.:Emerald, p. chapter 15

Winston C (1981) A disaggregate model of the demand for intercity freight. Econometrica 49:981–1006

Transek (1990). Godskunders värderingar, Banverket (Rapport 9 1990:2)

Transek (1992) Godskunders transportmedelsval, Vägverket (Rapport 1992:25)

Bergkvist E, Westin L (2000) Regional valuation of infrastructure and transport attributes in Swedish road freight. Umeå Econ Stud 546

Bergkvist E (2001). Freight transportation: valuation of time and forecasting of flows. Umeå Econ Stud 549

INREGIA (2001) Tidsvärden och transportkvalitet, INREGIA

Halse AH, et al. (2010) Verdsetting av famføringstid og pålitelighet i godstransport, Oslo: Transportøkonomisk institutt (TØI rapport 1083/2010)

Halse AH, Killi M (2012) Verdsetting av tid og pålitelighet for godstransport på jernbane, Oslo: TØI (TØI rapport 1189/2012)

Kurri J, Sirkiä A, Mikola J (2000) Transp Res 1725:26–30

de Jong G, Gommers M, Klooster J (1992) Time valuation in freight transport: methods and results. Paper presented at the XXth Summer Annual Meeting, PTRC, Manchester

HCG (1992) De reistijdwaardering in het goederenvervoer, The Hague: Rapport Hoofdonderzoek, Report 142–1 for Rijkswaterstaat, Dienst Verkeerskunde, HCG (Hague Consulting Group)

RAND Europe (2004) De Waardering van kwaliteit en betrouwbaarheid in personen- en goederen vervoer (The valuation of quality and reliability in passenger and freight transport). Rotterdam, RAND Europe

Bogers E, van Zuylen H (2005) De rol van betrouwbaarheid bij routekeuze van vrachtwagenchauffeurs (The importance of reliability in route choices of truck drivers). Tijdschr Vervoerwetenschap 41(3):26–30

Hamer R, Jong GD, Kroes E (2005) The value of reliability in Transport – Provisional values for the Netherlands based on expert opinion, s.l.: RAND (Technical Report Series, TR-240-AVV, Netherlands)

de Jong G et al (2009) Preliminary monetary values for the reliability of travel times in freight transport. Eur J Transp Infrastruct Res 9(2):83–99

Significance, Amsterdam, V. U., Bates J (2007) The value of travel time and travel time reliability, Survey design: Final Report prepared for the Netherlands Ministry of Transport, Public Works and Water Management)

Significance, et al. (2012) Values of time and reliability in passenger and freight transport in The Netherlands (Report for the Ministry of Infrastructure and the Environment)

Accent & Hague Consulting Group (1995) The value of travel time on UK roads – 1994. Final report, Report for the Department of Transport, Accent and HCG, Accent and Hague Consulting Group

Fowkes T (2007) The design and interpretation of freight stated preference experiments seeking to elicit behavioural valuations of journey attribute. Transp Res B 41:966–980

Fowkes A, Firmin P, Whiteling A, Tweedle G (2001) Freight road user valuations of three different aspects of delay. Paper presented at the European Transport Forum, s.n

de Jong G, Vellay C, Houée M, (2001) A joint SP/RP model of freight shipments from the region Nord-pas de Calais. Paper presented at the European Transport Conference

Small KRN, Chu X, Lewis D (1999) Valuation of travel-time savings and predictability in congested conditions for highway user-cost estimation, s.l.: National Cooperative Highway Research Program, Washington, D.C Cooperative Highway (Report 431)

Wigan M, Rockliffe N, Thoresen T, Tsolakis D (2000) Valuing long-haul and metropolitan travel time and reliability. J. Transp Stat 83–89

Puckett S, Rose J (2009) Observed efficiency of a D-optimal design in an interactive agency choice experiment. Paper presented at the ICMC, Harrogate

Bruzelius N (1996). Företagens MA-kostnader och företagens kapitalkostnader för fordon, Två uppsatser om samhällsekonomiska effekter av vägåtgärder, Borlänge: Statens Vägverk (PPp Meddelande nr. 1)

Minken H (1997). Næringslivets nytte av raskere og mer pålitlig godstransport, Oslo: TØI (TØI-rapport 347/1997)

Krüger NA, Vierth I, de Jong G, Halse A, Killi M (2013). Value of freight time variability reductions, Stockholm: VTI (VTI-Notat N39-2013)

Significance, Goudappel Coffeng und NEA (2012) Erfassung des Indikators Zuverlässigket im Bewertungsverfahren der Bundesverkehrswegeplanung: Schlussbericht, Erstellt für: Bundesministerium für Verkehr, Bau und Stadtentwicklung, s.l.: Significance\

Bruzelius N (2001) The valuation of logistics improvements in CBA of transport, s.l.: SIKA (http://www.trafa.se/sv/Soksida/#query=The+valuation+of+logistics+improvements+in+CBA+of+transport)

de Jong G, Ben-Akiva M, Baak J (2008) Method report logistics model in the Swedish freight transport model system, s.l.: Significance

Vierth I (2012) Värdering av tidsvinster och högre tillförlitlighet för godstransporter, s.l.: VTI (VTI Notat 24–2012)

TNS & BVU (2014). Entwicklung eines Modells zur Berechnung von modalen Verlagerungen im Güterverkehr für die Ableitung konistenster Bewertungsansätze für die Bundesverkehrswegeplanung, Freiburg and München: BVU Beratergruppe Verkehr+ Umwelt & TNS Infratest (Vorläufiger Endbericht)

Krüger NA, Vierth I, Fakhraei FR (2013) Spatial temporal and size distribution of freight train delays: evidence from Sweden. CTS working paper 2013:8

Vierth I (2012) Vad skulle en likabehandling av trafikslagen innebära för näringslivets transportval: exemplidiering för ett antal varuslag och relationer. s.l.:CTS (CTS Working paper No 2012:20)

Trafikverket (2012) Samhällsekonomiska principer och kalkylvärden för transportsektorn: ASEK 5, Kapitel 8, Tid och kvalitet i godstrafik, Borlänge: Trafikverket blanc (Version 2012-05-16)

SIKA (2005) Kalkylvärden och kalkylmetoder (ASEK): en sammanfattning av Verksgruppens rekommendationer 2005, SIKA PM 2005:16

Acknowledgments

The authors would like to thank COOP for the access to the firm’s data and the Swedish Transport Administration and the Centre for Transport Studies (CTS) for funding. This paper has vastly benefited from comments received on an early version; we owe thanks to John Bates (John Bates Services, UK), Gerard de Jong (Significance & ITS Leeds), Askill Harkjerr Halse (TØI) and Lars Hultkrantz (Örebro University). We also thank the participants at the 2nd Swedish National Conference in Transportation Research in Gothenburg 22–23 October 2013 for valuable comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Krüger, N.A., Vierth, I. Precautionary and operational costs of freight train delays: a case study of a Swedish grocery company. Eur. Transp. Res. Rev. 7, 6 (2015). https://doi.org/10.1007/s12544-015-0155-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12544-015-0155-7