Abstract

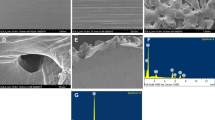

Longevity of cementless arthroplasty is determined by the characteristics of the porous structure formed at the surface. However, currently used artificial joint surface coating technologies have several limitations. Therefore, the goal of this study was to investigate the use of an artificial surface coating technology to overcome the limitations of currently used technologies. An artificial joint surface coating that controls porosity of the porous structure formed at the surface of the artificial joint was developed based on laser-aided direct metal tooling (DMT) technology, which is a three-dimensional (3-D) additive manufacturing (AM) technology. The structural, mechanical, and physical properties of the DMT surface coating was measured in accordance with the international testing standards and compared to titanium plasma spray (TPS) surface coating, a commercially available artificial joint surface coating. DMT exhibited characteristics comparable, if not better, than the existing commercial TPS in terms of mechanical and physical properties. DMT may be useful for cementless artificial joint surface coating required the porosity control of the porous structure formed at the surface of the artificial joint and provides enhanced longevity and patient prognosis compared to the existing surface coating technologies.

Similar content being viewed by others

References

Chiu, K. H., Shen, W. Y., Ko, C. K., and Chan, K. M., “Osteonecrosis of the Femoral Head Treated with Cementless Total Hip Arthroplasty: A Comparison with Other Diagnoses,” The Journal of Arthroplasty, Vol. 12, No. 6, pp. 683–688, 1997.

Beaul, P. E., Dorey, F. J., Hartley, W. T., McAuley, J. P., Culpepper, W. J., et al., “Survivorship Analysis of Cementless Total Hip Arthroplasty in Younger Patients,” The Journal of Bone and Joint Surgery-American, Vol. 83, No. 10, pp. 1590–1591, 2001.

Petsatodes, G. E., Christoforides, J. E., Papadopoulos, P. P., Christodoulou, A. G., Karataglis, D., and Pournaras, J. D., “Primary Total-Hip Arthroplasty with the Autophor 900-S Fully Porous Coated Stem in Young Patients: Seven to Seventeen Years of Follow-Up,” The Journal of Arthroplasty, Vol. 20, No. 4, pp. 436–442, 2005.

Viceconti, M., Brusi, G., Pancanti, A., and Cristofolini, L., “Primary Stability of an Anatomical Cementless Hip Stem: A Statistical Analysis,” Journal of Biomechanics, Vol. 39, No. 7, pp. 1169–1179, 2006.

Abdulkarim, A., Ellanti, P., Motterlini, N., Fahey, T., and O’Byrne, J. M., “Cemented Versus Uncemented Fixation in Total Hip Replacement: A Systematic Review and Meta-Analysis of Randomized Controlled Trials,” Orthopedic reviews, Vol. 5, No. 1, pp. 34–44, 2013.

Yamada, H., Yoshihara, Y., Henmi, O., Morita, M., Shiromoto, Y., et al., “Cementless Total Hip Replacement: Past, Present, and Future,” Journal of Orthopaedic Science, Vol. 14, No. 2, pp. 228–241, 2009.

Khanuja, H. S., Vakil, J. J., Goddard, M. S., and Mont, M. A., “Cementless Femoral Fixation in Total Hip Arthroplasty,” The Journal of Bone and Joint Surgery-American, Vol. 93, No. 5, pp. 500–509, 2011.

Zhang, B. G. X., Myers, D. E., Wallace, G. G., Brandt, M., and Choong, P. F., “Bioactive Coatings for Orthopaedic Implants-Recent Trends in Development of Implant Coatings,” International Journal of Molecular Sciences, Vol. 15, No. 7, pp. 11878–11921, 2014.

Albrektsson, T. and Johansson, C., “Osteoinduction, Osteoconduction and Osseointegration,” European Spine Journal, Vol. 10, No. 2, pp. S96–S101, 2001.

Balla, V. K., Banerjee, S., Bose, S., and Bandyopadhyay, A., “Direct Laser Processing of a Tantalum Coating on Titanium for Bone Replacement Structures,” Acta Biomaterialia, Vol. 6, No. 6, pp. 2329–2334, 2010.

Ryan, G., Pandit, A., and Apatsidis, D. P., “Fabrication Methods of Porous Metals for Use in Orthopaedic Applications,” Biomaterials, Vol. 27, No. 13, pp. 2651–2670, 2006.

Franchi, M., Orsini, E., Martini, D., Ottani, V., Fini, M., et al., “Destination of Titanium Particles Detached from Titanium Plasma Sprayed Implants,” Micron, Vol. 38, No. 6, pp. 618–625, 2007.

Saleh, K. J. and Schwarz, E. M., “Osteolysis: Medical and Surgical Approaches,” Clinical Orthopaedics and Related Research, Vol. 427, pp. 138–147, 2004.

Jones, L. C. and Hungerford, D. S., “Cement Disease,” Clinical Orthopaedics and Related Research, Vol. 225, pp. 192–206, 1987.

Abu-Amer, Y., Darwech, I., and Clohisy, J. C., “Aseptic Loosening of Total Joint Replacements: Mechanisms Underlying Osteolysis and Potential Therapies,” Arthritis Research & Therapy, Vol. 9, Suppl. 1, Paper No. S6, 2007.

Bi, Y., VanDe Motter, R. R., Ragab, A. A., Goldberg, V. M., Anderson, J. M., and Greenfield, E. M., “Titanium Particles Stimulate Bone Resorption by Inducing Differentiation of Murine Osteoclasts,” The Journal of Bone and Joint Surgery-American, Vol. 83, No. 4, pp. 501–501, 2001.

Harvey, E. J., Bobyn, J. D., Tanzer, M., Stackpool, G. J., Krygier, J. H., and Hacking, S., “Effect of Flexibility of the Femoral Stem on Bone-Remodeling and Fixation of the Stem in a Canine Total Hip Arthroplasty Model without Cement,” The Journal of Bone and Joint Surgery-American, Vol. 81, No. 1, pp. 93–107, 1999.

Chang, Y.-S., Gu, H.-O., Kobayashi, M., and Oka, M., “Influence of Various Structure Treatments on Histological Fixation of Titanium Implants,” The Journal of Arthroplasty, Vol. 13, No. 7, pp. 816–825, 1998.

Karageorgiou, V. and Kaplan, D., “Porosity of 3D Biomaterial Scaffolds and Osteogenesis,” Biomaterials, Vol. 26, No. 27, pp. 5474–5491, 2005.

Matassi, F., Botti, A., Sirleo, L., Carulli, C., and Innocenti, M., “Porous Metal for Orthopedics Implants,” Clinical Cases in Mineral and Bone Metabolism, Vol. 10, No. 2, pp. 111–115, 2013.

Bandyopadhyay, A., Espana, F., Balla, V. K., Bose, S., Ohgami, Y., and Davies, N. M., “Influence of Porosity on Mechanical Properties and in vivo Response of Ti-6Al-4V Implants,” Acta Biomaterialia, Vol. 6, No. 4, pp. 1640–1648, 2010.

ASTM F1044-05, “Standard Test Method for Shear Testing of Calcium Phosphate Coatings and Metallic Coatings,” 2005.

ASTM F1147-05, “Standard Test Method for Tension Testing of Calcium Phosphate and Metallic Coatings,” 2005.

ASTM F1978-00, “Standard Test Method for Measuring Abrasion Resistance of Metallic Thermal Spray Coatings by Using the TaberTM Abraser,” 2000.

Ellison, B., Berend, K. R., Lombardi, A. V., and Mallory, T. H., “Tapered Titanium Porous Plasma-Sprayed Femoral Component in Patients Aged 40 Years and Younger,” The Journal of Arthroplasty, Vol. 21, No. 6, pp. 32–37, 2006.

ISO 4288, “Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Rules and Procedures for the Assessment of Surface Texture,” 1996.

Oliveira, M. V., Pereira, L. C., and Cairo, C. A. A., “Porous Structure Characterization in Titanium Coating for Surgical Implants,” Materials Research, Vol. 5, No. 3, pp. 269–273, 2002.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shin, T., Park, SJ., Kang, K.S. et al. A laser-aided direct metal tooling technology for artificial joint surface coating. Int. J. Precis. Eng. Manuf. 18, 233–238 (2017). https://doi.org/10.1007/s12541-017-0030-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0030-7