Abstract

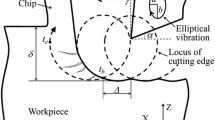

Recently, vibration assistance has been mainly applied to feed and cross-feed directions for milling processes. This paper investigates the effect of ultrasonic vibration assistance in tooling’s axial direction for improvement of machined surface with reduction of chatter marks. With the designed ultrasonic vibration assisted milling process with 39.7 kHz and a few micro-meter amplitudes, workpiece vibrates along tooling’s axial direction while various cutting speeds and feed rates are applied. In addition to a cutter rotation motion, the axial directional vibration assistance acts as additional cutting motion which further reduces the leftover surface error. Experimental results validate that surface roughness can be improved with the reduced chatter marks through the axial directional vibration assistance for the tested conditions. Finally, process simulation demonstrates that milling stability can be enhanced with the tooling’s ultrasonic vibration assistance, which explains the experimental phenomenon of the chatter marks reduction of the mesoscale milling processes.

Similar content being viewed by others

Abbreviations

- α:

-

rake angle

- σ:

-

helix angle

- β:

-

the angle between spindle velocity vector and cutting velocity vector with ultrasonic vibration

- π:

-

reference plane

- n⃗ :

-

normal vector to reference plane

- u⃗ :

-

ultrasonic vibration vector

- ν⃗ :

-

spindle velocity vector

- ρ⃗ :

-

cutting velocity vector with ultrasonic vibration

References

Brehl, D. E. and Dow, T. A., “Review of Vibration-Assisted Machining,” Precision Engineering, Vol. 32, No. 3, pp. 153–172, 2008.

Shamoto, E. and Moriwaki, T., “Ultraprecision Diamond Cutting of Hardened Steel by Applying Elliptical Vibration Cutting,” CIRP Annals — Manufacturing Technology, Vol. 48, No. 1, pp. 441–444, 1999.

Xiao, M., Sato, K., Karube, S., and Soutome, T., “The Effect of Tool Nose Radius in Ultrasonic Vibration Cutting of Hard Metal,” International Journal of Machine Tools & Manufacture, Vol. 43, No. 13, pp. 1375–1382, 2003.

Nath, C., Rahman, M., and Neo, K. S., “A Study on Ultrasonic Elliptical Vibration Cutting of Tungsten Carbide, Journal of Materials Processing Technology,” Vol. 209, No. 9, pp. 4459–4464, 2009.

Shamoto, E. and Moriwaki, T., “Study on Elliptical Vibration Cutting,” Annals of the CIRP, Vol. 43, No. 1, pp. 35–38, 1994.

Moriwaki, T., Shamoto, E., Song, Y. C., and Kohda, S., “Development of a Elliptical Vibration Milling Machine,” CIRP Annals — Manufacturing Technology, Vol. 53, No. 1, pp. 341–344, 2004.

Chern, G. L. and Chang, Y. C., “Using Two-Dimensional Vibration Cutting for Micro-Milling,” International Journal of Machine Tools & Manufacture, Vol. 46, No. 6, pp. 659–666, 2006.

Shen, X.-H., Zhang, J., Xing, D., and Zhao, Y., “A study of surface roughness variation in ultrasonic vibration-assisted milling,” International Journal of Advanced Manufacturing Technology, Vol. 58, No. 5–8, pp. 553–561, 2012.

Ko, J. H., Shaw, K. C., Chua, H. K., and Lin, R. M., “Cusp error reduction under high speed micro/meso-scale milling with ultrasonic vibration assistance,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 1, pp. 15–20, 2011.

Budak, E. and Altintas, Y., “Analytical Prediction of Chatter Stability in Milling-Part I: General Formulation,” ASME J. of Dyn. Sys., Meas., Control, Vol. 120, No. 1, pp. 22–30, 1998.

Budak, E. and Altintas, Y., “Analytical Prediction of Chatter Stability in Milling- Part II: Application of the General Formulation to Common Milling Systems,” ASME J. of Dyn. Sys., Meas., Control, Vol. 120, No. 1, pp. 31–36, 1998.

Ko, J. H. and Shaw, K. C., “Chatter Prediction in Frequency Domain for Pocket Milling,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 4, pp. 19–25, 2009.

Ko, J. H. and Altitntas, Y., “Dynamics and Stability of Plunge Milling Operation,” Journal of Manufacturing Science and Engineering, Vol. 129, No. 1, pp. 32–40, 2007.

Ko, J. H. and Altintas, Y., “Time Domain Model of Plunge Milling Operation,” International Journal of Machine Tools and Manufacture, Vol. 47, No. 9, pp. 1351–1361, 2007.

Altintas, Y. and Ko, J. H., “Chatter Stability of Plunge Milling,” CIRP Annals, Vol. 55, No. 1, pp. 361–364, 2006.

Yuan, Z. J., Zhou, M., and Dong, S., “Effect of diamond tool sharpness on minimum cutting thickness and cutting surface integrity in ultraprecision machining,” J. Mat. Proc. Tech., Vol. 62, pp. 327–330, 1996.

L’vov, N. P., “Determining the minimum possible chip thickness,” Machines & Tooling, Vol. 4, p. 45, 1969.

Son, S. M., Lim, H. S., and Ahn, J. H., “Effects of the friction coefficient on the minimum cutting thickness in micro cutting,” International Journal of Machine Tools and Manufacture, Vol. 45, No. 4–5, pp. 529–535, 2005.

Ko, J. H., Girsang, I. P., Vinay, R., Dhupia, J. S., and Shaw, K. C., “Surface Quality Assessment for Micro-Milling Applications under Various Cutting Conditions,” IMSEC — International Conference on Manufacturing Science and Engineering, pp. 333–341, 2009.

Liu, X., DeVor, R. E., and Kapoor, S. G., “An analytical model for the prediction of minimum chip thickness in micromachining,” Journal of Manufacturing Science and Engineering, Vol. 128, No. 2, pp. 474–481, 2006.

Li, H., Lai, X., Li, C., Feng, J., and Ni, J., “Modelling and experimental analysis of the effects of tool wear, minimum chip thickness and micro tool geometry on the surface roughness in micro-end-milling,” Journal of Micromechanics and Micro-Engineering, Vol. 18, No. 2, pp. 1–12, 2008.

Ko, J. H., “Plunge Milling Force Model using Instantaneous Cutting Force Coefficients,” Int. J. Precis. Eng. Manuf., Vol. 7, No. 3, pp. 8–13, 2006.

Ko, J. H. and Cho, D. W., “3D Ball-End Milling Force Model Using Instantaneous Cutting Force Coefficients,” Transactions of the ASME, Journal of Manufacturing Science and Engineering, Vol. 127, No. 1, pp. 1–12, 2005.

Ko, J. H. and Cho, D. W., “Determination of Cutting-Condition-Independent Coefficients and Runout Parameters in Ball-End Milling,” International Journal of Advanced Manufacturing Technology, Vol. 26, No. 11–12, pp. 1211–1221, 2005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ko, J.H., Tan, S.W. Chatter marks reduction in meso-scale milling through ultrasonic vibration assistance parallel to tooling’s axis. Int. J. Precis. Eng. Manuf. 14, 17–22 (2013). https://doi.org/10.1007/s12541-013-0003-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0003-4