Abstract

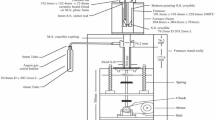

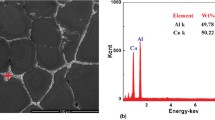

The present study evaluates the role of the microstructure in the static and dynamic mechanical behavior of as-cast Al7075 alloy promoted by ultrasonic treatment (US) during solidification. The characterization of samples revealed that US treatment promoted grain and intermetallics refinement, changed the shape of the intermetallic phases (equilibrium phases of soluble M and/or T (Al, Cu, Mg, Zn) and their insoluble Al-Cu-Fe compounds) and lead to their uniform distribution along the grain boundaries. Consequently, the mechanical properties and damping capacity above critical strain values were enhanced by comparison with values obtained for castings produced without US vibration. This results suggest that the grain and secondary phases refinement by US can be a promising solution to process materials to obtain high damping and high strength characteristics.

Similar content being viewed by others

References

T. Liu, Q. Wang, Y. Sui, Q. Wang, and W. Ding, Mater. Des. 68, 8 (2015).

H. Puga, J. Barbosa, N. Q. Tuan, and F. Silva, Trans. Nonferrous Met. Soc. China 24, 3459 (2014).

G. I. Eskin and D. G. Eskin, Ultrasonic Treatment of Light Alloy Melt, CRC Press, Boca Raton (2014).

H. Puga, S. Costa, J. Barbosa, S. Ribeiro, and M. Prokic, J. Mater. Process. Technol. 211, 1729 (2011).

N. Ono, R. Nowak, and S. Miura, 2004. Mater. Lett. 58, 39 (2004).

X. Li, S. M. Xiong, and Z. Guo, J. Mater. Sci. Technol. 32, 54 (2016).

J. Zhang, M. N. Gungor, and E. J. Lavernia, J. Mater. Sci. 28, 1515 (1993).

M. Colakoglu, J. Theor. Appl. Mech. 42, 95(2004).

W. B. Jiang, Q. P. Kong, P. Cui, Mater. Sci. Eng. A 527, 6028 (2010).

M. Blanter, I. Golovin, H. Neuhauser, and H. Sinning, Internal Friction in Metallic Materials, Springer, New York (2007).

A. J. Filmer, G. J. Hutton, and T. S. Hutchison, J. Appl. Phys. 29, 146 (1958).

A. Granato and K. Lücke, J. Appl. Phys. 27, 583 (1956).

L. Lihua, Z. Xiuqin, L. Xianfeng, W. Haowei, and M. Naiheng, Mater. Lett. 61, 231 (2007).

H. Watanabe, A. Owashi, T. Uesugi, Y. Takigawa, and K. Higashi, Philos. Mag. 91, 4158 (2011).

G. D. Fan, M. Y. Zheng, X. S. Hu, K. Wu, W. M. Gan, and H. G. Brokmeier 2013. Mater. Sci. Eng. A 561, 100 (2013).

R. H. Randall and C. Zener, Phys. Rev. 58, 472 (1940).

X. Cao and C. Huang, Mater. Sci. Eng. A 383, 341 (2004).

Y. Chen, Q. Wang, J. Lin, M. Liu, J. Hjelen, and H. J. Roven, Trans. Nonferrous Met. Soc. China 24, 3747 (2014).

Y. C. Lee, A. K. Dahle, and D. H. StJohn, Metall. Mater. Trans. A 31, 2895 (2000).

N. Q. Tuan, H. Puga, H. J. Barbosa, and A. M. P. Pinto, Met. Mater. Int. 21, 72 (2015).

Y. Ali, D. Qiu, B. Jiang, F. Pan, and M. X. Zhang, J. Alloys Compd. 619, 639 (2015).

W. Khalifa, Y. Tsunekawa, and M. Okumiya, J. Mater. Process. Technol. 210, 2178 (2010).

H. Puga, J. Barbosa, S. Costa, S. Ribeiro, A. M. P. Pinto, and M. Prokic, Mater. Sci. Eng. A 560, 589 (2013).

S. T. Lim, I. S. Eun, and S. W. Nam, Mater. Trans. 44, 181 (2003).

L. Chesini, I. Boromei, A. Morri, S. Seifeddine, I. L. Svensson, J. Mater. Process. Technol. 209, 5669 (2009).

X. Su, S. J. Wang, X. OuYang, P. Song, G. M. Xu, and D. H. Jiang. Mater. Sci. Eng. A 607, 10 (2014).

F. Rikhtegar and M. Ketabchi, Mater. Des. 31, 3943 (2010).

J. Gittus, Creep, Viscoelasticity, and Creep Fracture in Solids, Wiley, New York (1975).

A. Wolfenden and J. Wolla, J. Mater. Sci. 24, 3205 (1989).

X. S. Hu, K. Wu, M. Y. Zheng, W. M. Gan, and X. J. Wang, Mater. Sci. Eng. A 452, 374 (2007).

K. Nishiyama, R. Matsui, Y. Ikeda, S. Niwa, and T. Sakaguchi, 2003. Proc. Int. Symp. High Damping Mater. 355, 22 (2003).

D. Shenglong, L. Dabo, W. Tianzhen, and L. Chunyu, J. Mater. Sci. 33, 2227 (1988).

M. Tanaka and H. Iizuka, J. Mater. Sci. 26, 4389 (1991).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puga, H., Carneiro, V.H., Barbosa, J. et al. Effect of grain and secondary phase morphologies in the mechanical and damping behavior of Al7075 alloys. Met. Mater. Int. 22, 863–871 (2016). https://doi.org/10.1007/s12540-016-6073-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-6073-y