Abstract

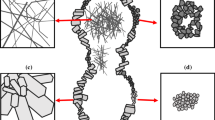

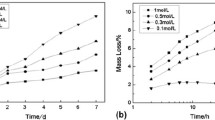

In the present study, porous self-bonded silicon carbide (SBSC) ceramics were fabricated at temperatures ranging from 1700 °C to 1800 °C using SiC powders, silicon and carbon as starting materials. The amount of (Si + C) powders is fixed and the influence of submicron SiC particle content (0 wt.% to 80 wt.%) on the porosity and strength of the ceramics was studied. The experimental results illustrate that the packing efficiency increased with the increase in submicron particle content to 40 wt.%, and thereafter decreased. The green porosity largely determines the final porosity of the sintered specimens, irrespective of the submicron SiC particle content. The flexural strength increased with the addition of submicron particle content and sintering temperature. Typically, SBSC ceramics prepared using 80 wt.% submicron SiC particle content possess 46% porosity and 42 MPa flexural strength when sintered at 1800 °C.

Similar content being viewed by others

References

P. Greil, Adv. Mater. 14, 709 (2002).

D. J. Green and P. Colombo, MRS Bull. 28, 296 (2003).

S. Kitaoka, Y. Matsushima, C. Chen, and H. Awaji, J. Am. Ceram. Soc. 87, 906 (2004).

J. Adler, Int. J. Appl. Ceram. Technol. 2, 429 (2005).

M. Fukushima, Y. Zhou, H. Miyazaki, Y. Yoshizawa, K. Hirao, Y. Iwamoto, S. Yamazaki, and T. Nagano, J. Am. Ceram. Soc. 89, 1523 (2006).

U. F. Vogt, L. Gyorfy, A. Herzog, T. Graule, and G. Plesch, J. Phys. Chem. Solids 68, 1234 (2007).

R. A. Wach, M. Sugimoto, and M. Yoshikawa, J. Am. Ceram. Soc. 90, 275 (2007).

M. H. Roh, Y.-W. Kim, W. Kim, T. Nishimura, W. S. Seo, S. I. Ko, and S. J. Lee, Met. Mater. Int. 15, 937 (2009).

B. V. Manoj Kumar, M. H. Roh, Y.-W. Kim, W. Kim, and S. W. Park, Met. Mater. Int. 16, 229 (2010).

J. H. Eom and Y.-W. Kim, Met. Mater. Int. 16, 399 (2010).

Y.-W. Kim, S. H. Kim, I. H. Song, H. D. Kim, and C. B. Park, J. Am. Ceram. Soc. 88, 2949 (2005).

R. Mouazer, S. Mullens, I. Thijs, J. Luyten, and A. Buekenhoudt, Adv. Eng. Mater. 7, 124 (2005).

Y. H. Choi, Y.-W. Kim, S. K. Woo, and I. S. Han, J. Kor. Ceram. Soc. 47, 509 (2010).

B. H. Yoon, E. J. Lee, H. E. Kim, and Y. H. Koh, J. Am. Ceram. Soc. 90, 1753 (2007).

I. C. Jung, S. H. Cho, S. W. Na, J. Lee, H. S. Lee, and W. S. Cho, Mater. Lett. 61, 4843 (2007).

A. Herzog, U. Vogt, O. Kaczmarek, R. Klingner, K. Richter, and H. Thoemen, J. Am. Ceram. Soc. 89, 1499 (2006).

J. K. Kim, Y. J. Jo, S. C. Han, H. Y. Lee, and J. M. Lee, J. Kor. Inst. Met. & Mater. 47, 748 (2009).

J. H. Eom, Y.-W. Kim, I. H. Song, and H. D. Kim, J. Europ. Ceram. Soc. 28, 1029 (2008).

S. H. Chae, Y.-W. Kim, I. H. Song, H. D. Kim, and M. Narisawa, J. Europ. Ceram. Soc. 29, 2867 (2009).

S. Ding, Y. P. Zeng, and D. Jiang, Mater Sci Eng A 425, 326 (2006).

Y.-W. Kim, J. H. Eom, C. Wang, and C. B. Park, J. Am. Ceram. Soc. 91, 1361 (2008).

J. H. Eom and Y.-W. Kim, J. Mater. Sci. 44, 4482 (2009).

S. Shimada, M. Murata, and M. Narisawa, J. Am. Ceram. Soc. 92, 21 (2009).

S. H. Chae and Y.-W. Kim, J. Mater. Sci. 44, 1404 (2009).

B. V. Manoj Kumar and Y.-W. Kim, Sci. Tech. Adv. Mater. 11, 044303 (2010).

G. S. Oleinik and L. A. Shipilova, Powder Metall. Met. Ceram. 20, 338 (1981).

L. I. Fedotova, A. G. Rozenblat, A. I. Rekov, V. A. Chivrikov, and V. E. Serebrennikova, Refrac Indust Ceram, 13, 271 (1972).

J. H. Eom, Y.-W. Kim, S. K. Woo, and I. S. Han, J. Ceram. Soc. Japan 117, 421 (2009).

Y. Nurishi and J. A. Pask, Ceram. Int. 8, 57 (1982).

B. V. M. Kumar, J. H. Eom, Y.-W. Kim, I. S. Han, and S. K. Woo, J. Ceram. Soc. Japan 118, 13 (2010).

H. Takahashi, N. Shinohara, K. Uematsu, and J. Tsubaki, J. Am. Ceram. Soc. 79, 843 (1996).

Y. Zhang, M. Inoue, N. Uchida, and K. Uematsu, J. Mater. Res. 14, 3370 (1999).

N. Shinohara, S. Katori, M. Okumiya, T. Hotta, K. Nakahira, M. Naito, Y. I. Cho, and K. Uematsu, J. Eur. Ceram. Soc. 22, 2841 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manoj Kumar, B.V., Lim, KY. & Kim, YW. Influence of submicron SiC particle addition on porosity and flexural strength of porous self-bonded silicon carbide. Met. Mater. Int. 17, 435–440 (2011). https://doi.org/10.1007/s12540-011-0621-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-011-0621-2