Abstract

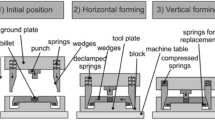

In each industrial process for the production of crankshafts a low energy demand and a fast processing time are required. Crankshafts have a very complex geometry and are forged with a high percentage of flash compared to other forging parts. Recent research showed the feasibility of a flashless forging of crankshafts. One way to forge a flashless crankshaft within three steps is to use cross wedge rolling, multi-directional forging and final forging. This paper presents the investigation results regarding the influence of the forming angle α in cross wedge rolling on different parameters at multi-directional forging. First, the state of the art is presented. As a basis for the investigations the process development and tool design of cross wedge rolling and multi-directional forging are described. Afterwards the paper’s results regarding the influence of the forming angle α on flash generation, billet temperatures, forming degree, forming forces and effective strain will be presented as a parameter study. Generally, flash is generated because a rotation-symmetric billet is forced into an asymmetric movement. The influence of an increasing forming angle leads to a higher amount of flash at the bottom of the crankwebs.

Similar content being viewed by others

References

Kache H, Stonis M, Behrens BA (2012) Development of a warm cross wedge rolling process using FEA and downsized experimental trials. Prod Eng Res Devel. doi:10.1007/s11740-012-0379-5

Li Q, Lovell M (2008) Cross wedge rolling failure mechanisms and industrial application. Int J Adv Manuf Technol. doi:10.1007/s00170-007-0979-y

Pater Z (2003) Tools optimization in cross wedge rolling. J Mater Process Technol 139(153):–159

Kache H, Nickel R, Behrens, BA (2011) An innovative cross wedge rolling preforming operation for warm forging. 4th conference on Changeable, Agile, reconfigurable and virtual production (CARV 2011), October 2nd–5th 2011, Montreal, pp 310–315

Pater Z (2000) Theoretical and experimental analysis of cross wedge rolling Process. Int J Mach Tools Manuf 40:49–63. doi:10.1016/S0890-6955(99)00047-4

Li Q, Lovell MR, Slaughter WS, Tagavi K (2002) Investigation of the morphology of internal defects in cross wedge rolling. J Mater Process Technol. doi:10.1016/S0924-0136(02)00303-5

Dong Y, Tagavi K, Lovell MR, Deng Z (2000) Analysis of stress in cross wedge rolling with application to failure. Int J Mech Sci. doi:10.1016/S0020-7403(99)00035-1

Behrens BA, Bouguecha A, Suchmann P, Schott A (2008) Warm forging: new forming sequence for the manufacturing of long flat pieces. Prod Eng Res Devel 2:261–268. doi:10.1007/s11740-008-0114-4

Behrens BA et al (2013) Basic study on the process combination of deposition welding and subsequent hot bulk forming. Prod Eng Res Devel. doi:10.1007/s11740-013-0478-y

Meyer M, Stonis M, Behrens B-A (2012) Cross Wedge Rolling of Preforms for Crankshafts. Key Eng Mater 504–506:205–210. doi:10.4028/www.scientific.net/KEM.504-506.205

Meyer M, Stonis M, Behrens BA (2015) Cross wedge rolling and bi-directional forging of preforms for crankshafts. Prod Eng Res Devel. doi:10.1007/s11740-014-0581-8

Doege E, Hustedt P, Altmann C, Specker A, Meyer, M (2003) Precision forging of crankshafts. WGP production enigneering. Research and development. Band 10 (2003), Heft 2, Seite 29–34

Behrens BA, Doege E, Reinsch S, Telkamp K, Daehndel H, Specker A (2007) Precision Forging Processes for High-Duty Automotive Components. J Mater Process Technol 185:139–146. doi:10.1016/j.jmatprotec.2006.03.132

Behrens BA, Nickel R, Müller S (2009) Flashless precision forging of a two-cylinder crankshaft. Prod Eng Res Devel 3:381–389. doi:10.1007/s11740-009-0185-x

Awiszus B, Neugebauer R, Kittner K, Popp P (2009) Analyse des querfließpressens als analogieversuch zum strangpressen unter besonderer berücksichtigung der verbundbildung zwischen aluminium und magnesium. UTF science. Online journal, no.4, S. 18

Acknowledgment

The authors thank the German Research Foundation (Deutsche Forschungsgemeinschaft ¬– DFG) for the funding of the research project “ProKomb – Prozesskombination des Querkeilwalzens mit der mehrdirektionalen Umformung” (DFG STO 1011/5-1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This study was funded by the German Research Foundation (Deutsche Forschungsgemeinschaft – DFG, STO 1011/5–1). The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Behrens, BA., Stonis, M. & Rasche, N. Influence of the forming angle in cross wedge rolling on the multi-directional forging of crankshafts. Int J Mater Form 11, 31–41 (2018). https://doi.org/10.1007/s12289-016-1326-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1326-3