Abstract

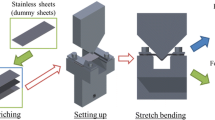

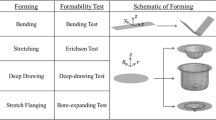

The deformation of carbon-fiber-reinforced plastic (CFRP) sheets consisting of a thermosetting resin and continuous fibers has been investigated. The bending of CFRP sheets was achieved under a suitable forming temperature and strain path. Formability indexes and a forming limit diagram (FLD) are indispensable data for showing the process window of CFRP sheets. There are four formability indexes: bendability, deep drawability, stretchability, and stretch-flangeability. Bendability and deep drawability can be evaluated by conducting a stretch-bending test, and stretchability can be evaluated by conducting an Erichsen cupping test. If the process window can be predicted, the range of applications using CFRP can be expanded. In this study, the Erichsen index of CFRP sheets indicates the stretchability of laminated CFRP structures.

Similar content being viewed by others

References

Hull D, Clyne TW (1981) An introduction to composite materials. Cambridge Solid State Science Series, 9–38

“Advanced High Strength Steel Application Guidelines”, International Iron & Steel Institute, ver. 4.1, 2009.

Bigg DM, Preston JR (1989) Stamping of thermoplastic matrix composites. Polym Compos 10(4):261–268

González-Romero VM, Macosko CW (1990) Process parameters estimation for structural reaction injection molding and resin transfer molding. Polym Eng Sci 30(3):142–146

Kendall KN, Rudd CD, Owen MJ, Middleton V (1992) Characterization of the resin transfer moulding process. Compos Manuf 3-4:235–249

Henninger F, Friedrich K (2002) Thermoplastic filament winding with online-impregnation. Part a: process technology and operating efficiency. Compos A: Appl Sci Manuf 33(11):1479–1486

Yanagimoto J, Ikeuchi K (2012) Sheet forming process of carbon fiber reinforced plastics for lightweight parts. CIRP Annals-Manufacturing Technology 61(1):247–250

Jeong C, Oya T, Yanagimoto J (2013) Analysis of fracture behavior and stress–strain distribution of martensite/austenite multilayered metallic sheet. J Mater Process Technol 213(4):614–620

Cao S, Zhis WU, Wang X (2009) Tensile properties of CFRP and hybrid FRP composites at elevated temperatures. J Compos Mater 43(4):315–330

Takeda T, Takano S, Shindo Y, Narita F (2005) Deformation and progressive failure behavior of woven-fabric-reinforced glass/epoxy composite laminates under tensile loading at cryogenic temperatures. Compos Sci Technol 65(11):1691–1702

Miyano Y, Nakada M, Kasamori M, Muki R (2000) Effect of physical aging on the creep deformation of an epoxy resin. Mechanics of Time-Dependent Materials 4(1):9–20

Behzadi S, Jones FR (2005) Yielding behavior of model epoxy matrices for fiber reinforced composites: effect of strain rate and temperature. Journal of Macromolecular Science, Part B: Physics 44(6):993–1005

Uriya, Y., & Yanagimoto, J. (2015). Suitable structure of thermosetting CFRP sheet for cold/warm forming. International Journal of Material Forming, 1–10.

ISO, B. (2003) 20482: 2003, metallic materials–sheet and strip–Erichsen cupping test. British Standards Institution, London

Sarkar BK, Mukherjee MK, Natarajan A (1982) A modification of the rule of mixture in estimating strengths of a composite. Mater Werkst 13(8):269–273

Uriya Y, Ikeuchi K, Yanagimoto J (2015) Enhanced formability of thin carbon fiber reinforced plastic sheets in cold/warm embossing with ductile dummy sheets of different thicknesses. Int J Mater Form 8(3):415–421

Standard B, ISO B (1996) Plastics—determination of tensile properties—. Part 1:527–521

Lippmann H (1962) Principal line theory of axially-symmetric plastic deformation. Journal of the Mechanics and Physics of Solids 10(2):111–122

Chakrabarty J (1970) A theory of stretch forming over hemispherical punch heads. Int J Mech Sci 12(4):315–325

Tsukizoe T, Ohmae N (1983) Friction and wear of advanced composite materials. Fibre Science and Technology 18(4):265–286

Barker AJ, Vangerko H (1983) Temperature dependence of elastic constants of CFRP. Composites 14(1):52–56

Acknowledgments

This work was supported by a Grant-in-Aid for Scientific Research (A) (26249109) supported by the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uriya, Y., Yanagimoto, J. Erichsen cupping test on thermosetting CFRP sheets. Int J Mater Form 10, 527–534 (2017). https://doi.org/10.1007/s12289-016-1298-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1298-3