Abstract

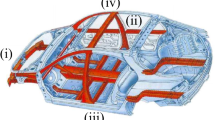

Roll forming is a continuous process in which a flat strip is incrementally bent to a desired profile. This process is increasingly used in automotive industry to form High Strength Steel (HSS) and Advanced High Strength Steel (AHSS) for structural components. Because of the large variety of applications of roll forming in the industry, Finite Element Analysis (FEA) is increasingly employed for roll forming process design. Formability and springback are two major concerns in the roll forming AHSS materials. Previous studies have shown that the elastic modulus (Young’s modulus) of AHSS materials can change when the material undergoes plastic deformation and the main goal of this study is to investigate the effect of a change in elastic modulus during forming on springback in roll forming. FEA has been applied for the roll forming simulation of a V-section using material data determined by experimental loading-unloading tests performed on mild, XF400, and DP780 steel. The results show that the reduction of the elastic modulus with pre-strain significantly influences springback in the roll forming of high strength steel while its effect is less when a softer steel is formed.

Similar content being viewed by others

References

Schuler GH (1998) Metal forming handbook. Berlin. Springer-Verlag, New York

Marnette J, Weiss M, Hodgson PD (2014) Roll-formability of cryo-rolled ultrafine aluminium sheet. Mater Des 63:471–478

Abeyrathna B, Rolfe B, Hodgson P, Weiss M (2015) A first step towards a simple in-line shape compensation routine for the roll forming of high strength steel. Int J Mater Form.:1–12

Groche P, Henkelmann M, Gotz P, Berner S (2008) Cold rolled profiles for vehicle construction. Archives of Civil and Mechanical Engineering 8:31–38

Weiss M, Marnette J, Wolfram P, Larranaga J, Hodgson P (2012) Comparison of bending of automotive steels in roll forming and in a V-die. Key Eng Mater 504-506:797–802

Eggertsen P, Mattiasson K (2009) On the modelling of the bending-unbending behaviour for accurate springback predictions. Int J Mech Sci 51:547–563

Mendiguren J, Cortés F, Gómez X, Galdos L (2015) Elastic behaviour characterisation of TRIP 700 steel by means of loading–unloading tests. Mater Sci Eng A 634:147–152

de Vin LJ, Streppel AH, Singh UP, Kals HJJ (1996) A process model for air bending. J Mater Process Technol. 57:48–54

Morestin F, Boivin M, Silva C (1996) Elasto plastic formulation using a kinematic hardening model for springback analysis in sheet metal forming. J Mater Process Technol 56:619–630

H. Kim and M. Kimchi (2011) Numerical Modeling for Springback Predictions by Considering the Variations of Elastic Modulus in Stamping Advanced High-Strength Steels (AHSS), in 8th International Conference and Workshop on Numerical Simulation of 3d Sheet Metal Forming Processes. K. Chung, H. N. Han, H. Huh, F. Barlat, and M. G. Lee, Eds., ed Melville: Amer Inst Physics, vol. 1383:pp. 1159–1166.

Yang M, Akiyama Y, Sasaki T (2004) Evaluation of change in material properties due to plastic deformation. J Mater Process Technol 151:232–236

Yu HY, Shen JY (Nov 2014) Evolution of mechanical properties for a dual-phase steel subjected to different loading paths. Mater Des 63:412–418

Fei D, Hodgson P (2006) Experimental and numerical studies of springback in air v-bending process for cold rolled TRIP steels. Nucl Eng Des 236:1847–1851

Li XC, Yang YY, Wang YZ, Bao J, Li SP (2002) Effect of the material-hardening mode on the springback simulation accuracy of V-free bending. J Mater Process Technol. 123:209–211

Chatti S, Hermi N (Jul 2011) The effect of non-linear recovery on springback prediction. Comput Struct 89:1367–1377

Chongthairungruang B, Uthaisangsuk V, Suranuntchai S, Jirathearanat S (2012) Experimental and numerical investigation of springback effect for advanced high strength dual phase steel. Mater Des 39:318–328

Chatti S (2013) Modeling of the elastic modulus evolution in unloading-reloading stages. Int J Mater Form. 6:93–101

Chatti S, Fathallah R (2014) A study of the variations in elastic modulus and its effect on springback prediction. Int J Mater Form. 7:19–29

Yu HY (2009) Variation of elastic modulus during plastic deformation and its influence on springback. Mater Des 30:846–850

Yoshida F, Uemori T, Fujiwara K (2002) Elastic-plastic behavior of steel sheets under in-plane cyclic tension-compression at large strain. Int J Plast 18:633–659

Mendiguren J, Trujillo JJ, Cortés F, Galdos L (2013) An extended elastic law to represent non-linear elastic behaviour: Application in computational metal forming. Int J Mech Sci. 77:57–64

Chatti S, Hermi N (2011) The effect of non-linear recovery on springback prediction. Comput Struct 89:1367–1377

Eggertsen PA, Mattiasson K (2010) On constitutive modeling for springback analysis. Int J Mech Sci 52:804–818

Eggertsen P-A, Mattiasson K (2011) On the identification of kinematic hardening material parameters for accurate springback predictions. Int J Mater Form 4:103–120

Abvabi A, Mendiguren J, Rolfe B, Weiss M (2014) Springback investigation in roll forming of a V-section. Applied Mechanics and Materials 553:643–648

(2015). Tokyo Sokki Kenkyujo Co., Ltd. Available: https://www.tml.jp/e/product/strain_gauge/catalog_pdf/YEF_YF_YUFseries.pdf

DataM. (2014). COPRA® RF Available: http://www.datam.de/en/products-solutions/roll-forming

A. Abvabi, (2014) Effect of Residual Stresses in Roll Forming Process of Metal Sheets Ph.D., School of Engineering - Faculty of Science, Engineering and Built Environment, Deakin University.

(2013) MSC.Marc, Volume B: Element Library. USA: MSC.Software Corporation.

Li KP, Carden WP, Wagoner RH (2002) Simulation of springback. Int J Mech Sci 44:103–122

Abvabi A, Rolfe B, Larrañaga J, Galdos L, Yang C, Weiss M (2012) "Using the solid-shell element to model the roll forming of large radii profiles," presented at the 14th international metal forming conference. Krakow, Poland

Hibbeler RC (2008) Mechanics of materials, 7th ed. Prentice Hall, Upper Saddle River, N.J.

Gere JM, Goodno BJ (2009) Mechanics of materials, SI ed. Stamford, conn. United Kingdom, Cengage Learning

Cobo R, Pla M, Hernández R, Benito J (2009) "analysis of the decrease of the apparent young’s modulus of advanced high strength steels and its effect in bending simulations," in Proceedings of the IDDRG 2009 International Conference. Golden, CO, USA

Z. Marciniak, J. Duncan, and J. Hu, Mechanics of sheet metal forming: Butterworth-Heinemann, 2002.

Wiebenga JH, Weiss M, Rolfe B, van den Boogaard AH (2013) Product defect compensation by robust optimization of a cold roll forming process. J Mater Process Technol 213:978–986

Groche P, Mueller C, Traub T, Butterweck K (Jan 2014) Experimental and numerical determination of roll forming loads. Steel Research International 85:112–122

Acknowledgments

The authors appreciate the financial support of the Australian Research Council (ARC Linkage grant - LP120100111). The authors would further like to thank Emeritus Professor J.L. Duncan for his assistance in writing this paper and dataM Sheet Metal Solutions GmbH for providing advice and access to their software package Copra-RF.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abvabi, A., Mendiguren, J., Kupke, A. et al. Evolution of elastic modulus in roll forming. Int J Mater Form 10, 463–471 (2017). https://doi.org/10.1007/s12289-016-1295-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1295-6