Abstract

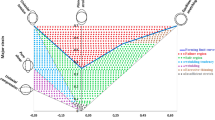

Aiming at the enhancement of the lightweight potential of press hardening steels, investigations on the formability of thin, boron alloyed, hot dip aluminized steel sheets are carried out. The material formability is described through Forming Limit Diagram (FLD), determined by means of Nakajima formability test of thin 22MnB5 sheets (0.50 mm, 0.80 mm, 1.25 mm) at elevated temperatures. The influence of sheet thickness on forming limits is evaluated under both isothermal and non-isothermal conditions. The effect of different deformation start temperatures is examined. The non-isothermal behavior is further investigated via microstructural analysis and a study on temperature profile during Nakajima test. The results show a significant difference regarding the influence of sheet thickness under isothermal and non-isothermal conditions. Increasing the sheet thickness results, as expected, in higher forming limits for isothermal conditions, whereas for non-isothermal conditions the opposite effect on formability is observed. The obtained Forming Limit Curves (FLCs) are validated through hot stamping simulation and subsequent analysis of different thin components, concluding that in case of thin sheets the isothermal FLC constitutes a more conservative approach, while the non-isothermal one reaches the formability limits with higher accuracy.

Similar content being viewed by others

Notes

The formability tests are performed in the Department of Industrial Engineering, University of Padua.

The hot stamping trials are conducted at the Institute of Forming Technology and Lightweight Construction, TU Dortmund University.

References

Ahmadi, S., Eivani, A.R., Akbarzadeh, A., 2009. Experimental and analytical studies on the prediction of forming limit diagrams. Comput Mater Sci, Vol. 44, Issue 4, pp. 1252–1257.

Bariani, P.F., Bruschi, S., Ghiotti, A., Turetta, A., 2008. Testing formability in the Hot stamping of HSS, CIRP Ann Manuf Technol, Vol. 57, Issue 1, pp. 265–268.

Bariani, P.F., Bruschi, S., Ghiotti, A., Michieletto, F., 2013. Hot stamping of AA5083 aluminium alloy sheets, CIRP Ann Manuf Technol, Vol. 62, Issue 1, pp. 251–254.

Bruschi, S., Altan, T., Banabic, D., Bariani, P.F., Brosius, A., Cao, J., Ghiotti, A., Khraisheh, M., Merklein, M., Tekkaya, A.E., 2014. Testing and modelling of material behaviour and formability in sheet metal forming, CIRP Ann Manuf Technol, Vol. 63, Issue 2, pp. 727–749.

Chastel, Y., Dahan, Y., Massoni, E., Duroux, P., Wilsius, J., Hein, P., 2008. Formability of quenchable steels in hot stamping. The 9th international conference on Technology Of Plasticity, ICTP, gyeongiu, Korea, pp. 678–683.

Cui J, Sun G, Xu J, Huang X, Li G (2015) A method to evaluate the formability of high-strength steel in hot stamping. Mater Des 77:95–109

Dahan Y, Chastel Y, Duroux P, Wilsius J, Hein P, Massoni E (2007) Procedure for the experimental determination of a forming limit curve for USIBOR 1500 P. Int. Deep Drawing Research Group IDDRG, Gyor, Hungary, pp. 125–132

Dilmec, M., Halkaci, H.S., Ozturk, F., Livatyali, H., Yigit, O., 2013. Effects of sheet thickness and anisotropy on forming limit curves of AA2024-T4. The Int Journal of Advanced Manufacturing Technology, Vol. 67, Issue 9, pp. 2689–2700.

Fan, D. W., Park, R. B., Cho, Y. R., De Cooman, B. C., 2010. Influence of isothermal deformation conditions on the mechanical properties of 22MnB5 HPF Steel. Steel Research Int 81 (4), pp. 292–298.

Graf A, Hosford W (1993) Effect of changing strain paths on forming limit diagram of Al 2008-T4. Metallurgical Transactions A 24:2503–2512

Georgiadis, G., Weigert, P., Kurz, H., Alsmann, M., Engelhardt, P., Tekkaya, A.E., Scholtes, B., 2013. Untersuchung der Herstellbarkeit dünner Warmumformbauteile. 8. Erlanger Workshop Warmblechumformung, Erlangen, Germany, pp. 147–164.

Georgiadis G, Tekkaya AE, Weigert P, Weiher J, Kurz H (2014) Investigations on the manufacturability of Thin Press hardened steel components. Procedia CIRP 18:74–79

Hora, P.,Merklein, M., Tong, L.C.H., Lechler, J., 2007. Numerical and experimental evaluation of thermal dependent FLC (FLC-T). Int. Deep Drawing Research Group IDDRG, Tisza, M. (Edtr.): Proceedings of the IDDRG 2007 Conference, Gyor, Hungary, pp. 23–30.

Jang, J.-H., Lee, J.-H., Joo, B.-D., Moon, Y.-H., 2009. Flow characteristics of aluminum coated boron steel in hot press forming, Trans Nonferrous Metals Soc China, Vol. 19, Issue 4, pp. 913–916.

Karbasian, H., Tekkaya, A.E., 2010. A review on hot stamping. J Mater Process Technol, Vol. 210, Issue 15, pp. 2103–2118.

Karbasian H, Klimmek C, Brosius A, Tekkaya AE (2008) Numerical process design of hot stamping process based on optimized thermo-mechanical characteristics. In: 1st int. conf. Hot sheet metal forming of high-performance steel - CHS2, Kassel, Germany, pp, pp. 97–103

Keeler, S.P., Brazier, W.G., 1975. Relationship Between laboratory material characterization and press shop formability. Microalloying 75 Proceedings of the Conference, Union Carbide Corporation, pp. 517–530.

Krauer, J., Hora, P., 2012. Enhanced material models for the process design of the temperature dependent forming behavior of metastable steels. Int J Mater Form, Vol. 5, Issue 4, pp. 361–370.

Lechler, J., Merklein, M., 2008. Investigations on forming limits within hot stamping. 1st int. conf. Hot sheet metal forming of high-performance steel - CHS2, Kassel, Germany, pp. 55–61.

Lechler, J., 2009. Grundlegende Untersuchungen zur Beschreibung und Modellierung des Werkstoffverhaltens von presshärtbaren Bor-Manganstählen. PhD Thesis, LFT, University of Erlangen-Nuremberg.

Lee, M., Baeck, S., Kang, C., 2012. Investigation of thin boron steel sheet formability in hot deep-drawing processes according to process parameters. proc. of the institution of mechanical engineers, part B, J. of Engineering Manufacture, Vol. 226, no. 5, pp. 898–908.

Li, H., Wu, X., Li, G., 2013. Prediction of forming limit diagrams for 22MnB5 in Hot stamping process. J Mater Eng Perform, Vol. 22, Issue 8, pp. 2131–2140.

Li, F. F., Fu, M. W., Lin, J. P., Wang, X. N., 2014. Experimental and theoretical study on the hot forming limit of 22MnB5 steel. the international J. of Advanced Manufacturing Technology4, Vol. 71, Issue 1, pp. 297–306.

López-Chipres E, Mejía I, Maldonado C, Bedolla-Jacuinde A, Cabrera JM (2007) Hot ductility behavior of boron microalloyed steels. Mater Sci Eng A 460–461:464–470

Min, J., Lin, J., 2011. Investigation on dynamic recovery behavior of boron steel 22MnB5 under austenite state at elevated temperatures. SAE International Journal of Materials and Manufacturing, Vol. 4, Issue 1, pp. 1147–1154.

Nakajima, K., Kikuma, T., Asaku, K., 1968. Study on the formability of steel sheet. Yawata Technical Report, no. 264.

Neugebauer R, Schieck F, Polster S, Mosel A, Rautenstrauch A, Schönherr J, Pierschel N (2012) Press hardening – an innovative and challenging technology. Archives of Civil and Mechanical Engineering 12:113–118

Pellegrini, D., Lechler, J., Ghiotti, A., Bruschi, S., Merklein, M., 2009. Interlaboratory comparison of forming limit curves for Hot stamping of high strength steels-padova, Erlangen. Key Eng Mater 410-411, pp. 297–304.

Sheng, Z., 2012. A temperature and time dependent forming limit surface for sheet metal forming at elevated temperatures. SAE Int J Mater Manf Vol. 5, Issue 2, pp. 277–284.

Shi DY, Ying L, Hu P, Lu JD, Zhao X (2013) Experimental and numerical determination of thermal forming limit diagrams (TFLD) of high strength steel 22MnB5. AIP Conf Proc 1532:406–413

Stoughton, T. B., 2000. A general forming limit criterion for sheet metal forming. Int J Mech Sci, Vol. 42, Issue 1, pp. 1–27.

Turetta, A., Bruschi, S., Ghiotti, A., 2006. Investigation of 22MnB5 formability in Hot Stamping Operations. J. of Materials Processing Technology, vol. 177, Issues 1-3, pp. 396–400.

Zhang, J., 2007. Optimization of contact forces in tailor-welded blanks forming process. The Int J of Advanced Manufacturing Technology, Vol. 33, Issue 5, pp. 460–468.

Zhao K, Chang Y, Hu P, Wu Y (2016) Influence of rapid cooling pretreatment on microstructure and mechanical property of hot stamped AHSS part. J Mater Process Technol 228:68–75

Acknowledgment

The authors would like to sincerely thank Dr. M. Alsmann from Volkswagen Kassel for his support and the invaluable discussions within the scope of the current work. Thanks are due to S. Samadi from Volkswagen Wolfsburg for his support during the metallographic analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Disclaimer

The results, opinions or conclusions of this manuscript are not necessarily those of the Volkswagen AG.

Additional information

Research highlights

• Formability determination of thin (0.50, 0.80 and 1.25 mm) 22MnB5 sheets at elevated temperatures through FLCs.

• Contrary effect of thickness on formability at isothermal and non-isothermal conditions.

• The isothermally deformed specimens possess in general higher formability levels than the non-isothermally deformed ones.

• Temperature at isothermal conditions and work hardening at non-isothermal conditions are dominant factors regarding the formability of thin sheets.

• In case of thin sheets the isothermal FLC constitutes a more conservative approach, while the non-isothermal one reaches the formability limits with higher accuracy.

Rights and permissions

About this article

Cite this article

Georgiadis, G., Tekkaya, A.E., Weigert, P. et al. Formability analysis of thin press hardening steel sheets under isothermal and non-isothermal conditions. Int J Mater Form 10, 405–419 (2017). https://doi.org/10.1007/s12289-016-1289-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1289-4