Abstract

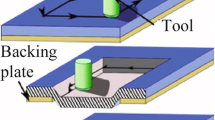

Single Point Incremental Forming (SPIF) is a promising manufacturing technology concerning the production of customized products, low batches or prototyping of ready-to-use parts, given its easy implementation and absence of dedicated tooling. The range of application is wide, covering many materials and virtually unlimited geometries. Indeed, nowadays’ process downsides are more related to high forming times and dimensional inaccuracy. There are many processing parameters that can be optimized to circumvent such problems. In this work, focus is given on the effect of increasing tool feed rate. To this end, a dedicated SPIF machine is employed. After forming steel and aluminum sheets, parameters like forming force, maximum wall angle and formability are assessed for a range of velocities from 1500 to 12,000 mm/min. Parameters like step down or tool diameters are kept constant for a clear comparison. It will be shown how the process can be fastened up without seriously compromising its feasibility.

Similar content being viewed by others

References

Jeswiet J, Micari F, Hirt G, Bramley N, Duflou J, Allwood J (2006) Asymmetric single point incremental forming of sheet metal”. CIRP Annals 54:623–650

Alves de Sousa RJ, Ferreira JAF, Sá de Farias JB, Torrão JND, Afonso DG, Martins MABE (2014) SPIF-A: on the development of a new concept of incremental forming machine. SEM Struct Eng Mech 49(5):645–660. doi:10.12989/sem.2014.49.5.645

Ambrogio G, Filice L, Gagliardi F (2012) Improving industrial suitability of incremental sheet forming process. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3448-6

Ambrogio G, Gagliardi F, Bruschi S, Filice L (2013) On the high-speed Single Point Incremental Forming of titanium alloys. CIRP Annals—Manufacturing Technology 62(Issue 1):243–246. doi:10.1016/j.cirp.2013.03.053, ISSN 0007–8506

Hamilton K, Jeswiet J (2010) Single point incremental forming at high feed rates and rotational speeds: surface and structural consequences. Annals CIRP 59(1):311–314

Camara J (2009) Single Point Incremental Forming, Master Thesis, Instituto Superior Tecnico, Lisbon

Bastos RP (2014) Control of a servo-hydraulic platform using parallel kinematics for incremental forming, MSc. Thesis, University of Aveiro

Ghulam H, Nasir H, Gao L (2012) Pyramid as test geometry to evaluate formability in incremental forming: Recent results. J Mech Sci Technol 26(8):2337–2345. doi:10.1007/s12206-012-0617-y, www.springerlink.com/content/1738-494x

Azevedo NG, Farias JS, Bastos RP, Teixeira P, Davim JP, Alves de Sousa RJ (2015) Lubrication aspects during Single Point Incremental Forming for steel and aluminum materials. Int J Precis Eng Manuf 16(Issue 3):589–595. doi:10.1007/s12541-015-0079-0

Liu Z, Liu S, Li Y, Meehan PA (2014) Modeling and optimization of surface roughness in incremental sheet forming using a multi-objective function. Mater Manuf Process 29(7):808–818. doi:10.1080/10426914.2013.864405

Allwood JM, Houghton NE, Jackson KP (2005) The design of an Incremental Forming machine, 11th Conference on Sheet Metal, pp 471–478, Erlangen

Filice L, Fratini L, Micari F (2002) Analysis of material formability in incremental forming. CIRP Ann Manuf Technol 51(Issue 1):199–202. doi:10.1016/S0007-8506(07)61499-1, ISSN 0007–8506

Duflou JR, Verbert J, Belkassem B, Gu J, Sol H, Henrard C, Habraken AM (2008) Process window enhancement for single point incremental forming through multi-step toolpaths. CIRP Ann Manuf Technol 57(Issue 1):253–256. doi:10.1016/j.cirp.2008.03.030, ISSN 0007–8506

Hussain G, Dar NU, Gao L, Chen MH (2007) A comparative study on the forming limits of an aluminum sheet-metal in negative incremental forming. J Mater Process Technol 187–188:94–98

Martins PAF, Montanari L, Cristino VA, Silva MB (2014) Formability and Simulative Tests in Modern Sheet Metal Forming Education, Modern Mechanical Engineering, Materials Forming, Machining and Tribology, Springer, pp 411–447

Li Y, Liu Z, Lu H, Daniel WJT, Meehan PA (2014) Experimental study and efficient prediction on forming forces in incremental sheet forming. Adv Mater Res 939:313–321

Acknowledgments

The authors acknowledge Portuguese Science Foundation and Compete Program under grant EXPL/EMS-TEC/0539/2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pereira Bastos, R.N., Alves de Sousa, R.J. & Fernandes Ferreira, J.A. Enhancing time efficiency on single point incremental forming processes. Int J Mater Form 9, 653–662 (2016). https://doi.org/10.1007/s12289-015-1251-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-015-1251-x