Abstract

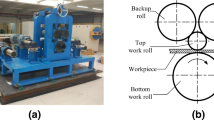

The demand for miniaturized parts and miniaturized semi-finished products is increasing nowadays, because microforming processes can improve production rate and minimize material waste due to less forming passes. However, traditional macro metal forming processes and modelling cannot be simply scaled down to produce miniaturized micro parts. In this study, a 2-Hi micro rolling mill has been successfully built. Experimental and numerical investigations on the micro rolling process for ultra-thin SUS 304 stainless steel strip have been conducted. The experimental results show that the micro rolling deformation of ultra-thin strip is influenced by size effect which results from the specimen size difference and this size effect is embodied in the flow stress and the friction coefficient. Analytical and finite element (FE) models in describing size effect related phenomena, such as flow stress, friction, rolling force and deformation behaviour, are proposed. The material surface constraint and the material deformation mode are critical in determination of material flow stress curve. The analysis of surface roughness evolution with rolling conditions has also been performed. The identified analysis on deformation mechanics provides a basis for further exploration of the material behaviour in plastic deformation of micro scale and the development of micro scale products via micro rolling.

Similar content being viewed by others

References

Engel U, Eckstein R (2002) Microforming – from basic research to its realization. J Mater Process Technol 125-126:35–44

Raulea LV, Goijaerts AM, Govaert LE, Baaijens FPT (2001) Size effects in the processing of thin metal sheets. J Mater Process Technol 115:44–48

Yeh FH, Li CL, Lu YH (2008) Study of thickness and grain size effects on material behavior in micro-forming. J Mater Process Technol 201:237–24

Parasiz SA, Kinsey BL, Mahayatsanun N, Cao J (2011) Effect of specimen size and grain size on deformation in microextrusion. J Manuf Process 13:153–159

Kals TA, Eckstein R (2000) Miniaturization in sheet metal working. J Mater Process Technol 103:95–101

Peng LF, Lai XM, Lee HJ, Song JH, Ni J (2010) Friction behaviour modelling and analysis in micro/meso scale metal forming process. Mater Des 31:1953–1961

Jeon J, Bramley AN (2007) A friction model for microforming. Int J Adv Manuf Technol 33:125–129

Xie HB, Manabe K, Jiang ZY (2013) A novel approach to investigate surface roughness evolution in asymmetric rolling based on three dimensional real surface. Finite Elem Anal Des 74:1–8

Wang GC, Zheng W, Wu T, JiangZ ZGQ, Wei DB, Jiang ZY (2013) A multi-region model for numerical simulation of micro bulk forming. J Mater Process Technol 212:678–684

Le H, Sutcliffe M (2006) A multi-scale model for friction in cold rolling of aluminium alloy. Tribol Lett 22:95–104

Le H, Sutcliffe M (2003) A friction model for cold strip rolling with two-wavelength surface roughness in the “mixed” lubrication regime. ASME J Tribol 125:670–677

Lugt P, Wemekamp A, Napel W, Liempt P, Otten J (1993) Lubrication in cold rolling: elasto-plasto-hydrodynamic lubrication of smooth surfaces. Wear 166:203–214

Xie HB, Jiang ZY, Du YB, Wei DB, Tieu AK (2009) Analysis of surface roughness of low carbon steel during cold rolling of thin strip. Adv Mater Res 76–78:544–547

Myshkin NK, Grigoriev AY, Chizhik SA, Choi KY, Petrokovets MI (2003) Surface roughness and texture analysis in microscale. Wear 254:1001–1009

Sutcliffe MPF (1988) Surface asperity deformation in metal forming process. Int J Mech Sci 30:847–868

Leu DK (2011) Modelling of surface roughness effect on dry contact friction in metal forming. Int J Manuf Technol 57:575–584

Utsunomiya H, Sutcliffe MPF, Shercliff HR, Bate PS, Miller DB (2005) Influence of friction on roughening of the matt surface in aluminum pack rolling. Int J Mach Tools Manuf 45:803–809

Tateno J, Hiruta T, Katsura S, Honda A, Miyata T, Kamimaru A (2011) Experimental analysis of thickness reduction limits in ultra thin stainless steel foil rolling. ISIJ Int 51:788–792

Yuen YWD, Dixon A, Nguyen DN (1996) The modelling of the mechanics of deformation in flat rolling. J Mater Process Technol 60:87–94

Zhang LC (1995) On the mechanism of cold rolling thin foil. Int J Mach Mach Mater 35:363–372

Langlands TAM, McElwain DLS (2002) A modified Hertzian foil model: approximations based on perturbation methods. Int J Mech Sci 44:1715–1730

Keife H, Shi JY, McElwain DLS, Langlands TAM (2002) Foil rolling: a new interpretation of experimental results. J Mater Process Technol 121:50–59

Shimizu T, Manabe K, Yang M (2010) Deformation behavior of ultra-thin metal foils in strip drawing friction test. Key Eng Mater 443:110–115

Acknowledgments

The authors would like to give thanks to Prof. Yoshino of Tokyo Institute of Technology and Prof. Koyama of Chiba University. The first author is grateful to the Japan Society for Promotion of Science (JSPS), Japan for awarding of JSPS post-doctoral fellowship (FY 2012–2014) to carry out research in Japan and the support from Australian Academy of Science (AAS). This research was supported by the Grant-in-Aid for JSPS Fellows relating to JSPS Post-doctoral Fellowship for Foreign Researchers (Grant No. 24.02770) from JSPS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, H.B., Manabe, K., Furushima, T. et al. An experimental and numerical investigation on micro rolling for ultra-thin strip. Int J Mater Form 9, 405–412 (2016). https://doi.org/10.1007/s12289-015-1229-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-015-1229-8