Abstract

Purpose

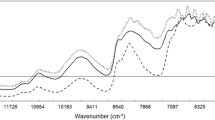

A near-infrared (NIR) spectroscopic method was developed for real time analysis of the active pharmaceutical ingredient (API) in blends from a continuous manufacturing process. The sampling and analytical errors of these determinations were estimated through variographic analysis.

Methods

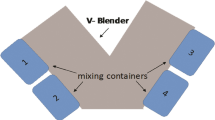

Thirty-three calibration blends were prepared in laboratory scale equipment with a concentration range spanning from 70 to 130% of API target concentration. The NIR calibration model was validated using three independent validation sets (prepared in laboratory and pilot plant facilities and in the CM equipment). Real-time NIR spectra were obtained with an interface where three NIR spectrometers monitored the CM process. A variographic study was performed with the NIR predictions of drug concentration in blends.

Results

A total of 1800 NIR spectra were obtained throughout a CM run that lasted 2.5 h. Two NIR spectrometers (M1 and M2) monitored the CM run while located in positions b-1 and b-3 of the sensing interface. These two positions yielded very similar results. The average NIR predictions for blends were 101.67% LC for the first run using spectrometer M1 and 103.60% LC with M2. The second run provided an average NIR prediction of 101.19% LC with M1 and 103.16% LC with M2. The average drug concentration in tablets was 100.63% LC for the first run and 100.42% LC for the second run. Variograms showed a low sill and a flat, stable variogram demonstrating good mixing of the blend.

Conclusion

The CM process provided tablets with excellent content uniformity. The sampling and analytical errors and the true process variation were easily discerned through variographic analysis.

Similar content being viewed by others

References

Vanarase AU, Alcalà M, Jerez Rozo JI, Muzzio FJ, Romañach RJ. Real-time monitoring of drug concentration in a continuous powder mixing process using NIR spectroscopy. Chem Eng Sci. 2010;65(21):5728–33. doi:10.1016/j.ces.2010.01.036.

Martínez L, Peinado A, Liesum L, Betz G. Use of near-infrared spectroscopy to quantify drug content on a continuous blending process: influence of mass flow and rotation speed variations. Eur J Pharm Biopharm. 2013;84(3):606–15.

Colón YM, Florian MA, Acevedo D, Méndez R, Romañach RJ. Near infrared method development for a continuous manufacturing blending process. J Pharm Innov. 2014;9(4):291–301.

Esbensen KH, Paasch-Mortensen P. Process Sampling: Theory of Sampling – the Missing Link in Process Analytical Technologies (PAT). Process Analytical Technology. John Wiley & Sons, Ltd; 2010. p. 37–80.

Anderson NG. Using continuous processes to increase production. Org Process Res Dev. 2012;16(5):852–69.

Yu L. Continuous Manufacturing Has a Strong Impact on Drug Quality. In: FDA Voice. http://blogs.fda.gov/fdavoice/index.php/2016/04/continuous-manufacturing-has-a-strong-impact-on-drug-quality/. 2016. Accessed July 23, 2016

Gray N. In first, FDA approves Janssen’s switch to continuous manufacturing for HIV drug. In: BioPharma Dive. http://www.biopharmadive.com/news/in-first-fda-approves-janssens-switch-to-continuous-manufacturing-for-hiv/417460/. 2016. Accessed July 23, 2016.

Brennan Z. FDA Allows First Switch From Batch to Continuous Manufacturing for HIV Drug. In: Regularoty affairs professionals society. http://raps.org/Regulatory-Focus/News/2016/04/12/24739/FDA-Allows-First-Switch-From-Batch-to-Continuous-Manufacturing-for-HIV-Drug/. 2016. Accessed July 23, 2016.

Langhauser K. Janssen’s Historic FDA Approval. The FDA has approved -- for the first time in history -- a manufacturer’s production method change from “batch” to continuous manufacturing. In: Pharmaceutical Manufacturing. http://www.pharmamanufacturing.com/articles/2016/janssens-historic-fda-approval/. 2016. Accessed July 23, 2016.

MacDonald G. Janssen working on other continuous processes post US FDA OK for Prezista. In: in-Pharma Technologist. http://www.in-pharmatechnologist.com/Processing/Janssen-working-on-other-continuous-processes-post-US-FDA-OK-for-Prezista?utm_source=copyright&utm_medium=OnSite&utm_campaign=copyright. 2016. Accessed July 23, 2016.

Allison G, Cain YT, Cooney C, Garcia T, Bizjak TG, Holte O, et al. Regulatory and quality considerations for continuous manufacturing. J Pharm Sci. 2015;104(3):803–12.

Schaber SD, Gerogiorgis DI, Ramachandran R, Evans JMB, Barton PI, Trout BL. Economic analysis of integrated continuous and batch pharmaceutical manufacturing: a case study. Ind Eng Chem Res. 2011;50(17):10083–92.

Mollan Jr MJ. Lodaya M. American Pharmaceutical Review: Continuous processing in pharmaceutical manufacturing; 2004.

McKenzie P, Kiang S, Tom J, Rubin AE, Futran M. Can pharmaceutical process development become high tech? AICHE J. 2006;52(12):3990–4.

McAuliffe MAP, O’Mahony GE, Blackshields CA, Collins JA, Egan DP, Kiernan L, et al. The use of PAT and Off-Line methods for monitoring of roller compacted ribbon and granule properties with a view to continuous processing. Org Process Res Dev. 2015;19(1):158–66.

Yu LX. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2008;25(4):781–91.

Blanco M, Bautista M, Alcala M. Preparing calibration sets for use in pharmaceutical analysis by NIR spectroscopy. J Pharm Sci. 2008;97(3):1236–45. doi:10.1002/jps.21105.

Meza CP, Santos MA, Romanach RJ. Quantitation of drug content in a low dosage formulation by transmission near infrared spectroscopy. AAPS PharmSciTech. 2006;7(1):E29. doi:10.1208/pt070129.

Blanco M, Cruz J, Bautista M. Development of a univariate calibration model for pharmaceutical analysis based on NIR spectra. Anal Bioanal Chem. 2008;392(7–8):1367–72.

Laasonen M, Harmia-Pulkkinen T, Simard C, Räsänen M, Vuorela H. Development and validation of a near-infrared method for the quantitation of caffeine in intact single tablets. Anal Chem. 2003;75(4):754–60.

Blanco M, Alcalá M. Content uniformity and tablet hardness testing of intact pharmaceutical tablets by near infrared spectroscopy. Anal Chim Acta. 2006;557(1–2):353–9.

Blanco M, Peguero A. Influence of physical factors on the accuracy of calibration models for NIR spectroscopy. J Pharm Biomed Anal. 2010;52(1):59–65. doi:10.1016/j.jpba.2009.12.009.

Isaksson T, Næs T. Selection of samples for calibration in near-infrared spectroscopy. Part II: selection based on spectral measurements. Appl Spectrosc. 1990;44(7):1152–8.

Iyer M, Morris H, Drennen III J. Solid dosage form analysis by near infrared spectroscopy: comparison of reflectance and transmittance measurements including the determination of effective sample mass. J Near Infrared Spectrosc. 2002;10(4):233–45.

Blanco M, Coello J, Eustaquio A, Iturriaga H, Maspoch S. Development and validation of a method for the analysis of a pharmaceutical preparation by near-infrared diffuse reflectance spectroscopy. J Pharm Sci. 1999;88(5):551–6. doi:10.1021/js980338f.

Stordrange L, Malthe-Sørenssen D, Høyland OM. Development of a multivariate calibration model of an organic process by near infrared spectroscopy. J Process Anal Chem. 2001;6:6–20.

Swierenga H, Wülfert F, de Noord OE, de Weijer AP, Smilde AK, Buydens LMC. Development of robust calibration models in near infra-red spectrometric applications. Anal Chim Acta. 2000;411(1–2):121–35.

Blanco M, Alcalá M, González JM, Torras E. A process analytical technology approach based on near infrared spectroscopy: tablet hardness, content uniformity, and dissolution test measurements of intact tablets. J Pharm Sci. 2006;95(10):2137–44.

Despagne F, Massart DL, Chabot P. Development of a robust calibration model for nonlinear in-line process data. Anal Chem. 2000;72(7):1657–65.

Kim T, Hwang S, Hyun S. Development of a continuous manufacturing process for silica sols via the ion-exchange of a Waterglass. Ind Eng Chem Res. 2008;47(18):6941–8.

Igne B, Zacour BM, Shi Z, Talwar S, Anderson CA, Drennen JK. Online monitoring of pharmaceutical materials using multiple NIR sensors—part I: blend homogeneity. J Pharm Innov. 2011;6(1):47–59.

Xiang D, Berry J, Buntz S, Gargiulo P, Cheney J, Joshi Y, et al. Robust calibration design in the pharmaceutical quantitative measurements with near-infrared (NIR) spectroscopy: avoiding the chemometric pitfalls. J Pharm Sci. 2009;98(3):1155–66. doi:10.1002/jps.21482.

Shi Z, Cogdill RP, Short SM, Anderson CA. Process characterization of powder blending by near-infrared spectroscopy: blend end-points and beyond. J Pharm Biomed Anal. 2008;47(4–5):738–45.

Liew CV, Karande AD, Heng PW. In-line quantification of drug and excipients in cohesive powder blends by near infrared spectroscopy. Int J Pharm. 2010;386(1–2):138–48.

Esbensen K. DS 3077 Representative Sampling–Horizontal Standard. Danish Standards. www. ds. dk; 2013.

Gy P. Sampling for analytical purposes. John Wiley & Sons; 1998.

Pitard FF. Pierre Gy’s sampling theory and sampling practice: heterogeneity, sampling correctness, and statistical process control. CRC Press; 1993.

Esbensen KH, Román-Ospino AD, Sanchez A, Romañach RJ. Adequacy and verifiability of pharmaceutical mixtures and dose units by variographic analysis (theory of sampling)–a call for a regulatory paradigm shift. Int J Pharm. 2016;499(1):156–74.

Wagner C, Esbensen KH. A critical review of sampling standards for solid biofuels – missing contributions from the theory of sampling (TOS). Renew Sust Energ Rev. 2012;16(1):504–17.

Rinnan Å. Berg Fvd, Engelsen SB. Review of the most common pre-processing techniques for near-infrared spectra. TrAC Trends Anal Chem. 2009;28(10):1201–22.

Barnes RJ, Dhanoa MS, Lister SJ. Standard normal variate transformation and de-trending of near-infrared diffuse reflectance spectra. Appl Spectrosc. 1989;43(5):772–7.

Despagne F, Massart D-L, de Noord OE. Optimization of partial-least-squares calibration models by simulation of instrumental perturbations. Anal Chem. 1997;69(16):3391–9.

Wülfert F. Temperature-robust multivariate calibration. Amsterdam: University of Amsterdam; 2004.

Blanco M, Coello J, Iturriaga H, Maspoch S, de la Pezuela C. Near-infrared spectroscopy in the pharmaceutical industry. Critical Review Analyst. 1998;123(8):135R–50R.

Bellamy LJ, Nordon A, Littlejohn D. Real-time monitoring of powder mixing in a convective blender using non-invasive reflectance NIR spectrometry. Analyst. 2008;133(1):58–64. doi:10.1039/b713919e.

Sanchez-Paternina A, Roman-Ospino AD, Martinez M, Mercado J, Alonso C, Romanach RJ. Near infrared spectroscopic transmittance measurements for pharmaceutical powder mixtures. J Pharm Biomed Anal. 2016;123:120–7.

Næs T, Isaksson T, Fearn T, Davies T. A user-friendly guide to multivariate calibration and classification. Chichester, West Sussex: NIR Publications; 2002.

Osorio JG, Vanarase AU, Romañach RJ, Muzzio FJ. Continuous Powder Mixing. Pharmaceutical Blending and Mixing. John Wiley & Sons, Ltd; 2015. p. 101–27

Hernandez E, Pawar P, Rodriguez S, Lysenko S, Muzzio FJ, Romanach RJ. Effect of shear applied during a pharmaceutical process on near infrared spectra. Appl Spectrosc. 2016;70(3):455–66.

Romañach R, Esbensen K. Proper sampling, total measurement uncertainty, variographic analysis & fit-for-purpose acceptance levels for pharmaceutical mixing monitoring. TOS Forum. 2015;5(5):25–30. doi:10.1255/tosf.68.

Acknowledgements

This project was funded by Johnson and Johnson in collaboration with the National Science Foundation Engineering Research Center for Structured Organic Particulate Systems (C-SOPS). The authors thank Kim Esbensen for helpful discussions on the variographic analysis and the Theory of Sampling.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vargas, J.M., Roman-Ospino, A.D., Sanchez, E. et al. Evaluation of Analytical and Sampling Errors in the Prediction of the Active Pharmaceutical Ingredient Concentration in Blends From a Continuous Manufacturing Process. J Pharm Innov 12, 155–167 (2017). https://doi.org/10.1007/s12247-017-9273-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-017-9273-1