Abstract

Introduction

The following paper describes the International Society for Pharmaceutical Engineering (ISPE)-sponsored Blend Uniformity and Content Uniformity Group’s proposed modifications to the withdrawn FDA draft guidance document for industry “Powder Blends and Finished Dosage Units—Stratified In-Process Dosage Unit Sampling and Assessment.” The modifications targeted FDA’s primary concerns that led to the withdrawal of the draft guidance document, which were insufficient blend uniformity testing and that a one-time passing of the criteria stated in USP General Chapter <905> Uniformity of Dosage Units testing lacks confidence to ensure the content uniformity of a batch.

Method

The Group’s approach discusses when triplicate blend samples should be analyzed and the importance of performing variance component analysis on the data to identify root causes of non-uniformity. The Group recommends the use of statistically based approaches, acceptance criteria, and sampling plans for assessing content uniformity for batch release that provide increased confidence that future samples drawn from the batch will comply with USP <905>. Alternative statistical approaches, sampling plans, and acceptance criteria, including modern analytical method (e.g., process analytical technology (PAT)) sampling plans, may be substituted for those mentioned in this paper, with justification. This approach also links blend and content uniformity testing to the three stages of the life cycle process validation approach.

Conclusion

A framework for the assessment of blend and content uniformity that provides greater assurance of passing USP <905> is presented.

Similar content being viewed by others

Notes

To avoid confusion with stage 1 and stage 2 testing for blend and dosage units described in the proposed approach, this paper will refer to the three stages of validation simply as “process design” (for stage 1 validation), “process qualification” (for stage 2 validation), and “continued process verification,” (for stage 3 validation).

Although the strategy described in this section can be applied to batches manufactured during stage 1 process design, the sampling plans, statistical approach, and acceptance criteria may be modified to be phase appropriate.

Fewer locations may be sampled for the assessment of smaller batches, with justification.

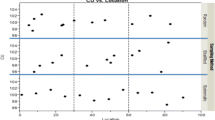

Variance component analysis is recommended if the standard deviation for the blend and/or dosage units is >3 %. After performing the VCA, attribute the variability to either variation in the uniformity of the blend and/or other causes depending on if one or both of the variance components (between and within location) are significant. Significant within-location variance (above that of the analytical method) in the blend data can be an indication of one factor or a combination of factors such as variation of the blend mix, sampling error, or agglomeration. Sampling errors of the blend will not carry over to the dosage units, while variation of the mix at the within-location scale, and/or agglomeration, can carry over to the dosage units. Significant between-location variance (above that of analytical method) in the blend data can indicate that the blending operation is not optimized or that segregation has occurred.

Although the strategy described in this section can be applied to batches manufactured during stage 1 process design, the sampling plans, statistical approach and acceptance criteria may be modified to be phase appropriate.

This example of a sampling plan was designed to provide appropriate data for estimating between-location and within-location variance components to meet FDA expectations [3].

Fewer locations may be sampled for the assessment of smaller batches, with justification.

Initial locations to be tested are identified prior to batch manufacture, and must be representative of the entire batch.

The manufacturer determines the number of dosage units to analyze during continued process verification, based on the results of process design and process qualification batch data, as well as the levels of producer and consumer risks they are willing to accept.

References

Guidance for industry, “Powder Blends and Finished Dosage Units—Stratified In-Process Dosage Unit Sampling and Assessment”. U.S. Department of Health and Human Services, Food and Drug Administration, Center for Drug Evaluation and Research (CDER), October 2003, Pharmaceutical CGMPs.

Federal Register / Vol. 78, No. 152, p. 48175-48176, August 7, 2013/Notices.

Questions and answers on current good manufacturing practices, good guidance practices, level 2 guidance—production and process controls. CDER/OC Office of Manufacturing and Product Quality: CGMP Subject Matter Contacts, 6 August 2013. http://www.fda.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/ucm124782.htm.

United States Pharmacopeia Convention, USP 37 NF 32, USP General Chapter <905> Uniformity of dosage units, general notices and requirements, Section 3.10, Applicability of standards.

“Stratified sampling” presented at 2013 ISPE Annual Meeting, Washington Marriott Wardman Park, Washington, DC, 3-6 November 2013

Bergum J. Current events in blend and content uniformity. Pharm Eng. 2014;34(2):1–10.

CFR 211.110, Code of Federal Regulations, Title 21, Volume 4, Revised as of April 1, 2014.

Guidance for industry, “Process Validation: General Principles and Practices,” U.S. Department of Health and Human Services, Food and Drug Administration, Center for Drug Evaluation and Research (CDER), Center for Biologics Evaluation and Research (CBER), Center for Veterinary Medicine (CVM), January 2011, Current Good Manufacturing Practices, Revision 1

Bergum J, Parks T, et.al. Assessment of blend and content uniformity: technical discussion of sampling plans and application of ASTM E2709/E2810, accepted for publication in J. Pharm. Innov., December, 2014

Bergum J., Tolerance interval alternative to ASTM E2709/E2810 methodology to provide assurance of passing the USP uniformity of dosage unit (UDU) test <905>, submitted to Pharmaceutical Engineering, October, 2014

De los Santos P, Liu J, Pfahler L, Harrington B, Vukovinsky K, “Performance characteristics and alternative approaches for the ASTM E2709/2810 (CUDAL) method for ensuring that a product meets USP <905> uniformity of dosage units”, Submitted to Pharmaceutical Engineering, October 2014

Tejwani R. “Relating blend uniformity specification to the finished product” presented at 2013 ISPE Annual Meeting, Washington Marriott Wardman Park, Washington, DC, November 6, 2013

Author information

Authors and Affiliations

Corresponding author

Additional information

The views presented in this article by the authors do not necessarily reflect those of their respective companies or organizations.

Rights and permissions

About this article

Cite this article

Garcia, T., Bergum, J., Prescott, J. et al. Recommendations for the Assessment of Blend and Content Uniformity: Modifications to Withdrawn FDA Draft Stratified Sampling Guidance. J Pharm Innov 10, 76–83 (2015). https://doi.org/10.1007/s12247-014-9207-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-014-9207-0