Abstract

Introduction

This study uses principal component analysis (PCA) to investigate deformation during powder compaction, in order to classify common pharmaceutical materials according to their relative plasticity.

Methods

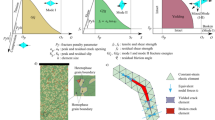

A variety of mechanical measurements were used during PCA modeling, including both applied force-dependent measurements and deformation parameters derived from various consolidation models. The applied force-dependent measurements included solid fraction, density change during elastic recovery, work of compression (w c ), work of decompression (w d ), normalized radial tensile strength (σT/σT, ε = 0), elasticity, and the work of compression and decompression (w c/d ). The models of consolidation included those proposed by Heckel, Walker, Alderborn, Gurnham, and Denny’s proposed modification to the Heckel model. The initial PCA model was calibrated based on 12, well-characterized pharmaceutical materials with a wide span of plastic, brittle, and elastic deformation properties.

Results and Conclusions

It was found that the first principal component seemed to be consistent with the relative plasticity of each material predicted by traditional methods. The variables contributing most to the variance explained by the first PC were found to be the c value from Gurnham model, w c , and w c/d . Further analysis of five additional materials indicated that the c value, alone, provided adequate differentiation of the materials’ relative plasticities. The advantages of multivariate analysis in analyzing the mechanical data and future application of PCA modeling are also discussed.

Similar content being viewed by others

References

Augsburger LL, Hoag SW. Pharmaceutical dosage forms: tablets, volume: 1. 3rd ed. New York: Informa Healthcare USA Inc; 2008.

Duberg M, Nystrom C. Studies on direct compression of tablets XVII. Porosity–pressure curves for the characterization of volume reduction mechanisms in powder compression. Powder Technol. 1986;46(1):67–75.

Heckel RW. Density–pressure relationships in powder compaction. Trans Met Soc AIME. 1961;221:671–5.

Heckel RW. An analysis of powder compaction phenomena. Trans Met Soc AIME. 1961;221:1001–8.

Gurnham CF, Masson HJ. Expression of liquids from fibrous materials. Ind Eng Chem. 1946;38(12):1309–15.

Walker EE. The properties of powders. Part VI: the compressibility of powders. Trans Faraday Soc. 1923;19:73–82.

Higuchi T, Nelson E, Busse LW. The physics of tablet compression. Determination of energy expenditure in the tablet compression process. J Am Pharm Assoc Sci Ed. 1955;44(4):223–5.

Celik M, Marshall K. Use of compaction simulator system in tableting research. Drug Dev Ind Pharm. 1989;15(5):759–800.

Aburub A, Buckner I, Mishra D. Use of compaction energetics for understanding particle deformation mechanism. Pharm Dev Technol. 2007;12(4):405–14.

Sonnergaard JM. A critical evaluation of the Heckel equation. Int J Pharm. 1999;193(1):63–71.

Rue PJ, Rees JE. Limitations of the Heckel relation for predicting powder compaction mechanism. J Pharm Pharmacol. 1978;30(10):642–3.

Jover I, Podczeck F, Newton M. Evaluation by a stastically designed experiment, of an experimental grade of microcrystalline cellulose, Avicel 955, as a technology to aid the production of pellets with high drug loading. J Pharm Sci. 1996;85(7):700–5.

Pinto JF, Podczeck F, Newton JM. Investigation of tablets prepared from pellets produced by extrusion and spheronisation. Part I: The application of canonical analysis to correlate the properties of the tablets to the factors studied in combination with principal component analysis to select the most relevant factors. Int J Pharm. 1997;147(1):79–93.

Pinto JF, Podczeck F, Newton JM. Investigation of tablets prepared from pellets produced by extrusion and spheronisation. II. Modelling the properties of the tablets produced using regression analysis. Int J Pharm. 1997;152(1):7–16.

Haware RV, Tho I, Bauer-Brandl A. Application of multivariate methods to compression behavior evaluation of directly compressible materials. Eur J Pharm Biopharm. 2009;72(1):148–55.

Haware RV, Tho I, Bauer-Brandl A. Multivariate analysis of relationships between material properties, process parameters and tablet tensile strength for α-lactose monohydrate. Eur J Pharm Biopharm. 2009;73(3):424–31.

Klevan I, Nordstrom J, Tho I, Alderborn G. A statistical approach to evaluate the potential use of compression parameters for classification of pharmaceutical powder materials. Eur J Pharm Biopharm. 2010;75(3):425–35.

Roopwani R, Buckner IS. Understanding deformation mechanisms during powder compaction using principal component analysis of compression data. Int J Pharm. 2011;418(2):227–34.

Bolhuis GK, Chowhan ZT. Materials for direct compression. In: Alderborn G, Nystrom C, editors. Pharmaceutical powder compaction technology. 1st ed. New York: Marcel Dekker Inc; 1996. pp. 429, 443, 458, 460, 470, 491.

Busignies V, Tchoreloff P, Leclerc B, Besnard M, Couarraze G. Compaction of crystallographic forms of pharmaceutical granular lactoses. I. Compressibility. Eur J Pharm Biopharm. 2004;58(3):569–76.

Hersey JA, Rees JE, Cole ET. Density changes in lactose tablets. J Pharm Sci. 1973;62(12):2060.

Sonnergard JM. Investigation of a new mathematical model for compression of pharmaceutical powders. Eur J Pharm Sci. 2001;14(2):149–57.

Schmidt PC, Herzog R. Calcium phosphates in pharmaceutical tableting. 2. Comparison of tableting properties. Pharm World Sci. 1993;15(3):116–22.

Podczeck F. Investigations into the fracture mechanics of acetylsalicylic acid and lactose monohydrate. J Mat Sci. 2001;36(19):4687–93.

Buckner IS, Wurster DE, Aburub A. Interpreting deformation behavior in pharmaceutical materials using multiple consolidation models and compaction energetics. Pharm Dev Technol. 2010;15(5):492–9.

Buckner IS. Compression calorimetry, powder compaction thermodynamics and deformation mechanisms, Ph.D. Thesis. University of Iowa, Iowa, 2008.

Denny PJ. Compaction equations: a comparison of the Heckel and Kawakita equations. Powder Technol. 2002;127(2):162–72.

Alderborn G. A novel approach to derive a compression parameter indicating effective particle deformability. Pharm Dev Technol. 2003;8(4):367–77.

Sun C, Grant DJW. Influence of elastic deformation of particles on Heckel analysis. Pharm Dev Technol. 2001;6(2):193–200.

Wise BM, et al. PLS_Toolbox 3.0 Manual, Eigenvector Research Inc.; 2003.

Rowe RC, Roberts RJ. Mechanical properties. In: Alderborn G, Nystrom C, editors. Pharmaceutical powder compaction technology. 1st ed. New York: Dekker; 1996. p. 283–322.

Rowlings CE, Wurster DE, Ramsey PJ. Calorimetric analysis of powder compression: II The relationship between energy terms measured with a compression calorimeter and tableting behavior. Int J Pharm. 1995;116(2):191–200.

Vachon MG, Chulia D. The use of energy indices in estimating powder compaction functionality of mixtures in pharmaceutical tableting. Int J Pharm. 1999;177(2):183–200.

Hiestand EN. Rationale for and the measurement of tableting indices. In: Alderborn G, Nystrom C, editors. Pharmaceutical powder compaction technology. 1st ed. New York: Dekker; 1996. p. 219–25.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roopwani, R., Shi, Z. & Buckner, I.S. Application of Principal Component Analysis (PCA) to Evaluating the Deformation Behaviors of Pharmaceutical Powders. J Pharm Innov 8, 121–130 (2013). https://doi.org/10.1007/s12247-013-9153-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-013-9153-2