Abstract

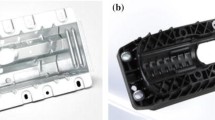

Invisible Passenger Airbag (IPAB) door system must be designed with a weakened area such that the airbag will break through the Instrument Panel (IP) in the intended manner, with no flying debris at any temperature. At the same time, there must be no cracking or sharp edges at the head impact test (ECE 21.01). Needless to say, Head impact test must keep pace with the deployment test. In this paper, we suggested soft airbag door system that is integrally molded with a hard instrument panel by using Two-shot molding. First of all, we set up the design parameters of IPAB door for the optimal deployment and head impact performance by CAE analysis. And then we optimized the open-close time at each gate of the mold so that the soft and hard material could be integrally molded with the intended boundary. We could make the boundary of two materials more constant by controlling the open-close time of each gate with resin temperature sensor.

Similar content being viewed by others

References

Christopher, L. C. and Deborah, J. L. (1996). High strain rate testing of engineer thermoplastics for head impact applications. SAE Paper No. 960153.

Dan, W., Jaya, D. and Sanjay, P. (2001). Predicting material processing degradation. SAE Paper No. 2001-01-1273.

Jaya, D. (2001). Modeling methodology of tearseams for invisible PSIR systems. SAE Paper No. 2001-01-0314.

Joseph, T. W. and Gerald, G. T. (1999). Material characterization for predicting impact performance of plastic parts. SAE Paper No. 1999-01-3178.

Kong, B. S., Park, J. G. and Bae, J. S. (2004). Invisible advanced passenger-side airbag door design for optimal deployment and head impact performance. SAE Paper No. 2004-01-0850.

Kumar, B. K., Scott, D. K. and Ravi, S. T. (1997). Using CAE to guide passenger airbag door design for optimal head impact performance. SAE Paper No. 970772.

Padraig, N. (1999). Extension of material models and finite element techniques to improve the simulation of high speed impact of thermoplastic materials. SAE Paper No. 1999-01-0300.

Simon, X. H. (1997). Advanced finite element analysis in the structural design of airbag modules. SAE Paper No. 970773.

Thomas, G. (2000). Materials modeling for engineering thermoplastics in FEA under high-strain loading. SAE Paper No. 2000-01-1167.

Tom Goral, V. N. and Robert, S. (1999). A predictive design methodology for active top pads during airbag deployment. SAE Paper No. 1999-01-0688.

Venkat, N. and Thomas, G. (1999). Material characterization and FEA correlation for engineering thermoplastics under high strain loading. SAE Paper No. 1999-01-3175.

Xinran, X. (2002). Plastic material modeling for FMVSS 201 simulation. SAE Paper No. 2002-01-0385.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, B.S., Park, D.K. Invisible PAB Door Development Using Two-Shot Molding. Int.J Automot. Technol. 20, 221–225 (2019). https://doi.org/10.1007/s12239-019-0021-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-019-0021-z