Abstract

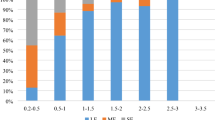

Since natural fiber/polymer composites are increasingly used, the development of safe and environmental friendly flame retarding bio-based composites is of great importance. But this issue must maintain the mechanical performance of these composites. To study these objectives, four levels of magnesium hydroxide Mg(OH)2 of (0, 10, 20, 30 phc) and two levels of nanoclay (0, 3 phc) were considered and incorporated into HDPE/wheat straw composites. Maleic anhydride grafted polyethylene (PE-g-MA) was also used as a compatibilizer at constant content. The samples were prepared by melt compounding and injection molding processes, respectively. The some properties of samples including burning rate and mechanical properties (tensile and impact strengths) were tested based on the ASTM standard. The results showed that the burning rate of samples decreased with increasing the nanoclay and Mg(OH)2 content. The tensile and impact strengths showed a marginal reduction by adding Mg(OH)2 from 10 phc to 30 phc and the tensile modulus and impact strength revealed an increase by increasing the amount of nanoclay up to 3 phc. Generally, these results confirmed that the fire retarding and mechanical properties of HDPE/wheat straw composites could be significantly improved with an appropriate combination of the nanoclay and Mg(OH)2 in the composites.

Similar content being viewed by others

References

A. Alemdar and M. Sain, Biores. Tech., 99, 6 (2008).

Y. Copur, C. Guler, M. Akgul, and C. Tascioglu, Build. Environ., 42, 2568 (2007).

X. F. Sun, R. C. Sun, J. Tomkinson, and M. S. Baird, Polym. Degrad. Stab., 83, 47 (2004).

N. M. White and M. P. Ansell, J. Mater. Sci., 18, 1549 (1983).

P. R. Hornsby, E. Hinrichsen, and K. Trivedi, J. Mater. Sci., 32, 443 (1997a).

P. R. Hornsby, E. Hinrichsen, and K. Trivedi, J. Mater. Sci., 32, 1009 (1997b).

L. Dobircau, P. A. Sreekumar, R. Saiah, N. Leblanc, C. Terrié, R. Gattin, and J. M. Saiter, Compos. Part A, 40, 329 (2009).

C. J. Hilado, “Flammability Handbook for Plastics”, 5th ed., Technomic Publishing Co., Lancaster, Pennsylvania, 1998.

M. Sain, S. H. Park, F. Suhara, and S. Law, Polym. Degrad. Stab., 83, 363 (2004).

N. Suppakarn and K. Jarukumjorn, Compos. Part B-Eng., 40, 613 (2009).

N. M. Stark, R. H. White, S. A. Mueller, and T. A. Osswald, Polym. Degrad. Stab., 95, 1903 (2010).

B. Li and J. He, Polym. Degrad. Stab., 83, 241 (2004).

S. Z. Matko, A. Toldy, S. Keszei, P. Anna, G. Y. Bertalan, and G. Y. Marosi, Polym. Degrad. Stab., 88, 138 (2005).

E. Gallo, B. Schartel, D. Acierno, and P. Russo, Eur. Polym. J., 47, 1390 (2011).

G. Beyer, Fire Mater., 26, 291 (2002).

T. Kashiwagi, F. Du, J. F. Douglas, K. I. Winey, R. H. Harris, and J. R. Shields, Nat. Mater., 4, 928 (2005).

J. W. Gilman, Appl. Clay Sci., 15, 31 (1999).

Y. Zhao, K. Wang, F. Zhu, P. Xue, and M. Jia, Polym. Degrad. Stab., 91, 2874 (2006).

M. Kozlowski, A. Iwanczuk, S. Frackowiak, and T. Szczurek, “Proceedings of the International Sustainable Materials, Polymers & Composites Conference”, Warwick, September 11–12, 2007.

B. Kord, J. Appl. Polym. Sci., 120, 607 (2011).

A. P. Mouritz and A. G. Gibson in “Fire Properties of Polymer Composite Materials” (G. M. L. Gladwell Ed.), pp.237–286, Springer, The Netherlands, 2006.

C. M. Liauw, R. N. Rothon, G. C. Lees, and I. Zafar, J. Adhes. Sci. Technol., 15, 889 (2001).

J. C. Yu, A. W. Xu, L. Z. Zhang, R. Song, and L. Wu, J. Phys. Chem. B, 108, 64 (2004).

J. W. Gilman, R. D. Davis, J. R. Shields, D. Wentz, L. D. Brassell, A. B. Morgan, R. Lyon, and J. E. Zanetto, “Proceedings of the International SAMPE Technical Conference”, San Diego, USA, November 15–18, 2004.

Z. X. Zhang, J. Zhang, B. X. Lu, Z. X. Xin, C. K. Kang, and J. K. Kim, Compos. Part B-Eng., 43, 150 (2011).

C. M. Koo, H. T. Ham, S. O. Kim, K. H. Wang, and I. Chung, Macromol., 35, 5116 (2002).

Q. Wu, Y. Lei, C. M. Clemons, F. Yao, Y. Xu, and K. Lian, J. Plast. Technol., 27, 108 (2007).

Y. Lei, Q. Wu, C. M. Clemons, F. Yao, and Y. Xu, J. Appl. Polym. Sci., 106, 3958 (2007).

H. Chen, M. Wang, Y. Lin, C. M. Chan, and J. Wu, J. Appl. Polym. Sci., 106, 3409 (2007).

S. K. Samal, S. Nayak, and S. Mohanty, J. Thermoplast. Compos., 21, 243 (2008).

A. Ashori and A. Nourbakhsh, J. Compos. Mater., 43, 1869 (2009).

J. Fu and H. E. Naguib, J. Cell. Plast., 42, 325 (2006).

L. S. Schadler in “Nanocomposite Science and Technology” (P. M. Ajayan, L. S. Schadler, and P. V. Braun Eds.), pp.77–154, Wiley-VCH Verlag, Weinheim, 2003.

S. Chapple and R. Anandjiwala, J. Thermoplast. Compos., 23, 871 (2010).

T. D. Hapuarachchi and T. Peijs, Compos. Part A-Appl. S., 41, 954 (2010).

G. I. Titleman, Y. Gonen, Y. Keidar, and S. Bron, Polym. Degrad. Stab., 77, 345 (2002).

J. Inne and A. Innes, Plast. Addit. Compound., 4, 22 (2002).

Y. Dong, D. Bhattacharyya, and P. J. Hunter, Compos. Sci. Technol., 68, 2864 (2008).

S. H. Chiu and W. K. Wang, J. Appl. Polym. Sci., 67, 989 (1998).

H. Dvira, M. Gottlieb, S. Darenb, and E. Tartakovskyb, Compos. Sci. Technol., 63, 1865 (2003).

E. A. J. Al-Mulla, Fiber. Polym., 12, 444 (2011).

A. Boukerrou, J. Duchet, S. Fellahi, M. Kaci, and H. Sautereau, J. Appl. Polym. Sci., 103, 3547 (2007).

T. C. Li, J. Ma, M. Wang, W. Chauhari, T. Liu, and W. Huang, J. Appl. Polym. Sci., 103, 1191 (2007).

P. Mareri, S. Bastide, N. Binda, and A. Crespy, Compos. Sci. Technol., 58, 747 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liany, Y., Tabei, A., Farsi, M. et al. Effect of nanoclay and magnesium hydroxide on some properties of HDPE/wheat straw composites. Fibers Polym 14, 304–310 (2013). https://doi.org/10.1007/s12221-013-0304-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-013-0304-3