Abstract

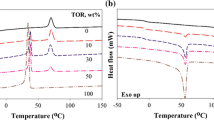

In this paper the peculiar shape memory property of semicrystalline PET films is studied. The shape memory samples were prepared through isothermal crystallization of glassy PET films at different temperatures between 120 and 230 °C for 15 and 4 minutes. It was assumed that the incorporated shape memory constitution is due to crystalline and amorphous parts and also third phase i.e. a rigid amorphous fraction (RAF) which rose by increasing the degree of crystallinity. The microstructure of samples was probed by DSC and WAXD analysis, and concluded that isothermal crystallization at temperature which spinodal decomposition mechanism is dominant, brings the formation of secondary crystal lamellas in amorphous regions between pre-existing lamellar stacks, incorporating shape recovery in the samples. As the crystallization proceeds with time or at higher temperatures, the fraction of RAF increases leading to suppression of shape memory effect.

Similar content being viewed by others

References

S. Thomas and P. M. Visakh, “Handbook of Engineering and Speciality Thermoplastics: Polyethers and Polyesters”, 1th ed., Vol. 3, pp.97–127, Wiley-Scrivener, 2011.

S. Fakirov(ed.), “Handbook of Thermoplastic Polyesters: Homopolymers, Copolymers, Blends and Composites”, Vol.1, Wiley-VCH, 2002.

S. Demeo, Science as Culture, 5, 352 (1996).

L. Cangémi and Y. Meimon, Oil & Gas Science and Technology — Rev. IFP, 56, 555 (2001).

J. L. Hu, “Shape Memory Polymers and Textiles”, Woodhead Pub., England, 2007.

A. Lendlein and S. Kelch, Angew. Chem. Int. Ed., 41, 2034 (2002).

T. Harai, H. Maruyama, T. Suzuki, and S. Hayashi, J. Appl. Polym. Sci., 45, 1849 (1992).

X. He, Y. Oishi, and A. Takahara, Polym. J., 28, 452 (1996).

Y. M. Lee, S. H. Kim, and C. S. Chao, J. Appl. Polym. Sci., 62, 310 (1996).

A. Lendlein and R. Langer, Science, 296, 1673 (2002).

W. Sokolowski, A. Metcalfe, and S. Hayashi, Biomed. Mater., 2, 23 (2007).

C. Liang Carogers, C. Rogers, and E. Malafeew, J. Intelligent Mater. Syst. Struct., 8, 380 (1997).

M. Behl and A. Lendlei, Mater. Today, 10, 20 (2007).

C. Liu, H. Qin, and P. T. Mather, J. Mater. Chem., 17, 1543 (2007).

M. Behl, M. Y. Razzaq, and A. Lendlein, Adv. Mater., 22, 3388 (2010).

D. Craig, V. Kett, J. Murphy, and D. Price, Pharmaceutical Research, 18, 1081 (2001).

W. Zhang, L. Chen, and Y. Zhang, Polymer, 50, 1311 (2009).

Y. S. Wong, Y. Xiong, S. S. Venkatraman, and F. Y. Cboey, J. Biomater. Sci., Polym. Ed., 19, 175 (2008).

Y. S. Wong and S. Venkatraman, Acta Materialia, 58, 49 (2010).

D. H. Cho, W. R. Yu, J. H. Youk, and J. H. Yoo, Eur. Polym. J., 43, 3562 (2007).

J. W. Cahn, J. Chem. Phys., 42, 93 (1965).

H. Furukawa, Adv. Phys., 34, 703 (1985).

J. I. Lauritzen and J. D. Hoffman, J. Appl. Phys., 44, 4340 (1973).

L. H. Sperling, “Introduction to Physical Polymer Science”, 4th ed., pp.153–163, Wiley-Interscience, New York, 2006.

M. Imai, K. Kaji, and T. Kanaya, Phys. Rev. Lett., 71, 4162 (1993).

N. J. Terrill, P. A. Fairclough, E. Towns-Andrews, B. U. Komanschek, R. J. Young, and A. J. Ryan, Polymer, 39, 2381 (1998).

E. L. Heeley, A. Maidens, P. D. Olmsted, W. Bras, I. P. Dolbnya, and J. P. A. Fairclough, Macromolecules, 36, 3656 (2003).

M. Imai, K. Kaji, and T. Kanay, Macromolecules, 27, 7103 (1994).

K. Nishida, K. Kaji, T. Kanaya, G. Matsuba, and T. Konisha, J. Polym. Sci. Pol. Phys., 42, 1817 (2004).

P. D. Olmsted, W. C. K. Poon, T. C. B. McLeish, N. J. Terrill, and A. J. Ryan, Phys. Rev. Lett., 81, 373 (1998).

P. G. Karagiannidis, A. C. Stergiou, and G. P. Karayannidis, Eur. Polym. J., 44, 1475 (2008).

J. D. Badia, E. Strömberg, S. Karlsson, and A. Ribes-Greus, Polym. Degrad. Stab., 97, 98 (2012).

R. Rastogi, W. P. Vellinga, S. Rastogi, C. Schick, and H. E. H. Meijer, J. Polym. Sci. Pol. Phys., 42, 2092 (2004).

J. D. Menczel, J. Therm. Anal. Calorim., 106, 7 (2011).

E. Abdel-Bary, “Handbook of Plastic Films”, p.247, Rapra Technology Limited, UK, 2003.

S. Fakirov, E. W. Fischer, and C. F. Schmidt, Makromol. Chem., 176, 2459 (1975).

D. Kawakami, B. S. Hsiao, S. Ran, C. Burger, B. Fu, I. Sics, B. Chu, and T. Kikutani, Polymer, 45, 905 (2004).

H. P. Klug and L. E. Alexander, “X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials”, John Wiley, New York, 1974.

T. Toda, H. Yoshida, and K. Fukunishi, Polymer, 36, 699 (1995).

L. Sirelli, R. A. Pereira, C. A. Perez, and M. L. Diaz, Macromol. Sci. B Phys., 45, 270 (2006).

M. Canetti and F. Bertini, Eur. Polym. J., 46, 270 (2010).

A. Flores, M. Pieruccinib, N. Stribeckc, S. S. Funarid, E. Boscha, and F. J. Baltá-Callejaa, Polymer, 46, 9404 (2005).

P. J. Holdsworth and A. Turner-Jones, Polymer, 12, 195 (1971).

J. D. Ferry, “Viscoelastic Properties of Polymers”, 3rd ed., Wiley-Interscience, New York, 1980.

B. Bhushan and H. Fuchs, “Applied Scanning Probe Methods III: Characterization”, p.85, Springer, Germany, 2006.

B. Wunderlich, “Thermal Analysis of Polymeric Materials”, Netherlands, Springer, 2005.

A. Mehta, U. Gaur, and B. Wunderlich, J. Polym. Sci. Polym Phys. Ed., 16, 289 (1978).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saatchi, E., Karimi, M. Incorporating shape memory properties in poly(ethylene terephthalate) film by isothermal crystallization. Fibers Polym 14, 208–215 (2013). https://doi.org/10.1007/s12221-013-0208-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-013-0208-2