Abstract

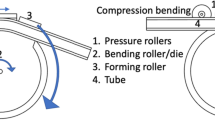

Rotary draw tube bending is one of the most complex tube forming processes subject to different process parameters such as material properties and geometry. This process is being practiced in more and more applications in industry due to its high efficiency, high forming precision and quality. However, improper process parameters can lead to wrinkling which restrict the thin walled tube bending. Therefore, the prediction and prevention of wrinkling is very important. Despite its importance, the effect of anisotropy on the occurrence of wrinkling was not considered in the literature up to now. In this investigation, a quantitative study on the wrinkling of thin walled tube bending is carried out through a finite element model of the process using velocity integral parameter, which is used for the detection of wrinkles. The other methods usually warn the wrinkling initiation with no precise location prediction. In addition, the effects of some process parameters, specially normal and planar anisotropy on the tube wrinkling are investigated. It is shown that increasing normal and planar anisotropy (increasing r0 and r90 values) result in a decrease in tube wrinkling.

Similar content being viewed by others

References

H. Li, H. Yang, M. Zhan and R. J. Gu, Forming characteristics of thin-walled tube bending process with small bending radius, Trans. Nonferrous Met. Soc. China, 16 (2006) 613–623.

H. Li, H. Yang, M. Zhan and R. J. Gu, A new method to accurately obtain wrinkling limit diagram in NC bending process of thin-walled tube with large diameter under different loading paths, J. Mater. Process. Technol, 117 (2006) 192–196.

H. Li, H. Yang, M. Zhan, Zh. Sun and R. Gu, Role of mandrel in NC precision bending process of thin-walled tube, Int. J. Mach. Tool. Manu, 47 (2007) 1164–1175.

H. Li, H. Yang, M. Zhan and R. J. Gu, The interactive effects of wrinkling and other defects in thin-walled tube NC bending process, J. Mater. Process. Technol, 187–188 (2007) 502–507.

H. Li, H. Yang, J. Yan and M. Zhan, Numerical study on deformation behaviors of thin-walled tube NC bending with large diameter and small bending radius, Comput. Mater. Sci, 45 (2009) 921–934.

H. Li, H. Yang, M. Zhan and Y. L. Kou, Deformation behaviors of thin-walled tube in rotary draw bending under push assistant loading conditions, J. Mater. Process. Technol, 210 (2010) 143–158.

A. Kumar, Optimizing the rotary draw tube bending process to avoid wrinkling, Int. J. Model. Simul, 28 (2008) 281–291.

L. G. Zhang and T. X. Yu, Modified adaptive dynamic relaxation method and its application to elastic-plastic bending and wrinkling of circular plates, Comput. Struct, 33 (1989) 609–614.

H. Yang, J. Yan, M. Zhan, H. Li and Y. Kou, 3D numerical study on wrinkling characteristics in NC bending of aluminum alloy thin-walled tubes with large diameters under multi-die constraints, Comput. Mater. Sci, 45 (2009) 1052–1067.

H. Li, H. Yang and M. Zhan, A study on plastic wrinkling in thin-walled tube bending via an energy-based wrinkling prediction model, Model. Simul. Mater. Sc, 17 (2009) 1–33.

H. Orban, G. Lin, S. J. Hu and M. Koc, Wrinkling detection in tube bending simulations, Transactions of NAMRI. SME, 35 (2007) 105–112.

M. Strano, Automatic tooling design for rotary draw bending of tubes, Int. J. Adv. Manuf. Technol, 26 (2005) 733–740.

H. Yang and L. Yan, Wrinkling analysis for forming limit of tube bending processes, J. Mater. Process. Technol, 152 (2004) 363–369.

X. Wang and J. Cao, Wrinkling limit in tube bending, J. Eng. Mater. Technol, 123 (2001) 430–435.

R. K. Miller, J. M. Hedgepeth, V. I. Weingarten, P. Das and Sh. Kahyai, Finite element analysis of partly wrinkled membranes, Comput. Struct, 20 (1985) 631–639.

R. J. Gu, H. Yang, M. Zhan, H. Li and H. W. Li, Research on the spring back of thin-walled tube NC bending based on the numerical simulation of the whole process, Comput. Mater. Sci, 42 (2008) 537–549.

H. Takahashi, J. Moro and Sh. Tsuchida, Plastic anisotropy in aluminium drawn tubes, Met. Mater, 4 (1998) 380–385.

Y. Kim and Y. Son, Study on wrinkling limit diagram of anisotropic sheet metals, J. Mater. Process. Technol, 97 (2000) 88–94.

I. Salehinia and A. R. Shahani, Effect of sheet anisotropy on the wear in deep-drawing process of a cylindrical cup, Int. J. Mech. Sci, 51 (2009) 856–868.

K. H. Kim, Evolution of anisotropy during twisting of cold drawn tubes, J. Mech. Phys. Solid, 40 (1992) 127–139.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Kyeongsik Woo

Kourosh Hasanpour graduated from Sharif University of Technology in 1999. He received his Ph.D from Isfahan University of Technology in 2006. He works as an assistant professor at University of Isfahan and is interested in continuum mechanics and plasticity.

Mahmoud Barati received his BSc. And MSc. Degrees in Mechanical engineering from Shahrekord University (Shahrekord, Iran) and K.N. Toosi Univercity of Technology (Tehran, Iran) in 2007 and 2010, respectively. Mr. Barati is currently a Ph.D student in the department of Mechanical Engineering, Isfahan University of Technology (Isfahan, Iran).

Behnaz Amini received her BSc. And MSc. Degrees in Mechanical engineering from Shahrekord University (Shahrekord, Iran) and Khomeinishahr Islamic Azad University (Isfahan, Iran) in 2007 and 2011, respectively.

Rights and permissions

About this article

Cite this article

Hasanpour, K., Barati, M., Amini, B. et al. The effect of anisotropy on wrinkling of tube under rotary draw bending. J Mech Sci Technol 27, 783–792 (2013). https://doi.org/10.1007/s12206-013-0124-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-013-0124-9