Abstract

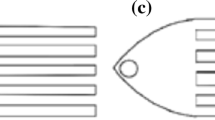

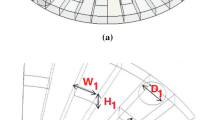

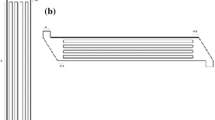

For efficient scale up of microchannel devices, uniform flow distribution to parallel microchannels is very important. In the present work, a dimensionless geometric parameter indicating the optimal manifold configuration is derived through a numerical parametric study and validated by micro particle image velocimetry. It is clearly shown that the flow uniformity is maximized when the dimensionless parameter is about 0.8. This study presents a simple and systematic design methodology for a uniform flow distribution to multiple microchannels operating in parallel.

Similar content being viewed by others

References

V. Hessel, S. Hardt and H. Löwe, Chemical micro process engineering: fundamentals, modeling and reactions, Wiley-VCH, Weinheim (2004).

V. Hessel, H. Löwe, A. Müller and G. Kolb, Chemical micro process engineering: processing and plants, Wiley-VCH, Weinheim (2005).

S. Balaji and S. Lakshminarayanan, Improved design of microchannel plate geometry for uniform flow distribution, The Canadian Journal of Chemical Engineering, 84 (2006) 715–721.

R. Chein and J. Chen, Numerical study of the inlet/outlet arrangement effect on microchannel heat sink performance, International Journal of Thermal Sciences, 48 (2009) 1627–1638.

J. M. Commenge, L. Falk, J. P. Corriou and M. Matlosz, Optimal design for flow uniformity in microchannel reactors, AIChE Journal, 48 (2002) 345–358.

E. R. Delsman, A. Pierik, M. H. J. M. de Croon, G. J. Kramer and J. C. Schouten, Microchannel plate geometry optimization for even flow distribution at high flow rates, Trans IChemE, Part A, 82(A2) (2004) 267–273.

G. Griffini and A. Gavriilidis, Effect of microchannel plate design on fluid flow uniformity at low flow rates, Chemical Engineering & Technology, 30 (2007) 395–406.

B. J. Jones, P.-S. Lee and S. V. Garimella, Infrared microparticle image velocimetry measurements and predictions of flow distribution in a microchannel heat sink, International Journal of Heat and Mass Transfer, 51 (2008) 1877–1887.

M. Pan, Y. Tang, L. Pan and L. Lu, Optimal design of complex manifold geometries for uniform flow distribution between microchannels, Chemical Engineering Journal, 137 (2008) 339–346.

V. Ponyavin, Y. Chen, J. Cutts, M. Wilson and A. E. Hechanova, Calculation of fluid flow distribution inside a compact ceramic high temperature heat exchanger and chemical decomposer, ASME Journal of Fluids Engineering, 130 (2008) 061104.

E. V. Rebrov, S. A. Duinkerke, M. H. J. M. de Croon and J. C. Schouten, Optimization of heat transfer characteristics, flow distribution, and reaction processing for a microstructured reactor/heat-exchanger for optimal performance in platinum catalyzed ammonia oxidation, Chemical Engineering Journal, 93 (2003) 201–216.

O. Tonomura, S. Tanaka, M. Noda, M. Kano, S. Hasebe and I. Hashimoto, CFD-based optimal design of manifold in plate-fin microdevices, Chemical Engineering Journal, 101 (2004) 397–402.

J. G. Santiago, S. T. Wereley, C. D. Meinhart, D. J. Beebe and R. J. Adrian, A particle image velocimetry system for microfluidics, Experiments in Fluids, 25 (1998) 316–319.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Jun Sang Park

Duckjong Kim is a senior researcher at Korea Institute of Machinery and Materials. He received his Ph.D degree in mechanical engineering from the Korea Advanced Institute of Science and Technology in 2003. His current research interests include micro/nano fluidics and thermal applications based on nano materials.

Cheong-Hwan Yu was a researcher of energy plant division at Korea Institute of Machinery and Materials. Currently, he is a research engineer at LG Electronics, Korea. His research interest includes flow control and measurement, micro- and bio fluid mechanics.

Seok Ho Yoon is a senior researcher of energy plant division at Korea Institute of Machinery and Materials. He received his Ph.D degree in School of Mechanical and Aerospace Engineering from Seoul National University, Korea, in 2002. His research interest includes heat pumps, heat exchangers, and equipments of energy plant.

Junseok Choi is a principal researcher of energy plant division at Korea Institute of Machinery and Materials. He received his Ph.D degree in Mechanical Engineering from Korea Advanced Institute of Science and Technology. His research interest includes compact heat exchangers, and valves of energy plant.

Rights and permissions

About this article

Cite this article

Kim, D., Yu, CH., Yoon, S.H. et al. Effects of manifold geometries on flow distribution to parallel microchannels. J Mech Sci Technol 25, 3069–3074 (2011). https://doi.org/10.1007/s12206-011-1220-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-011-1220-3